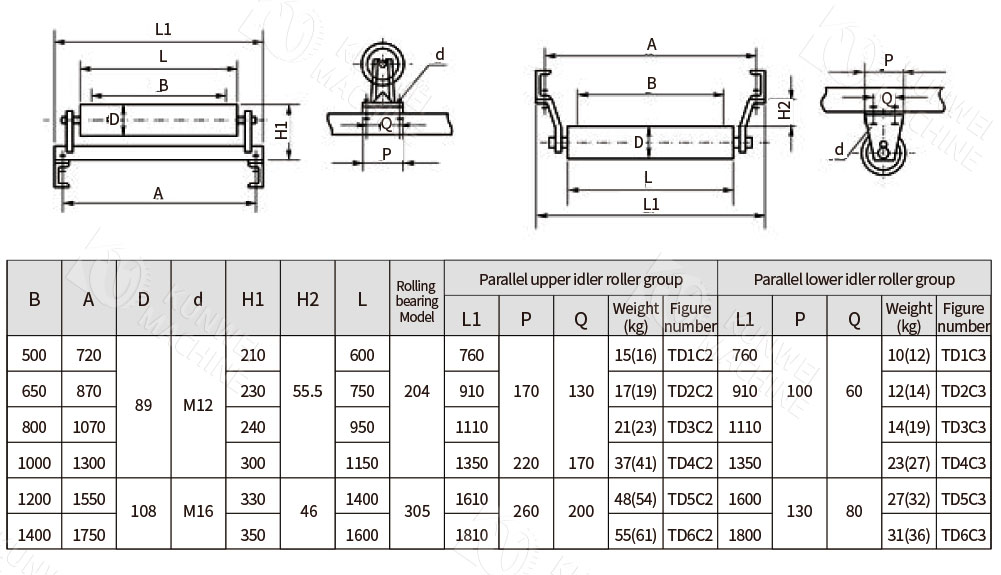

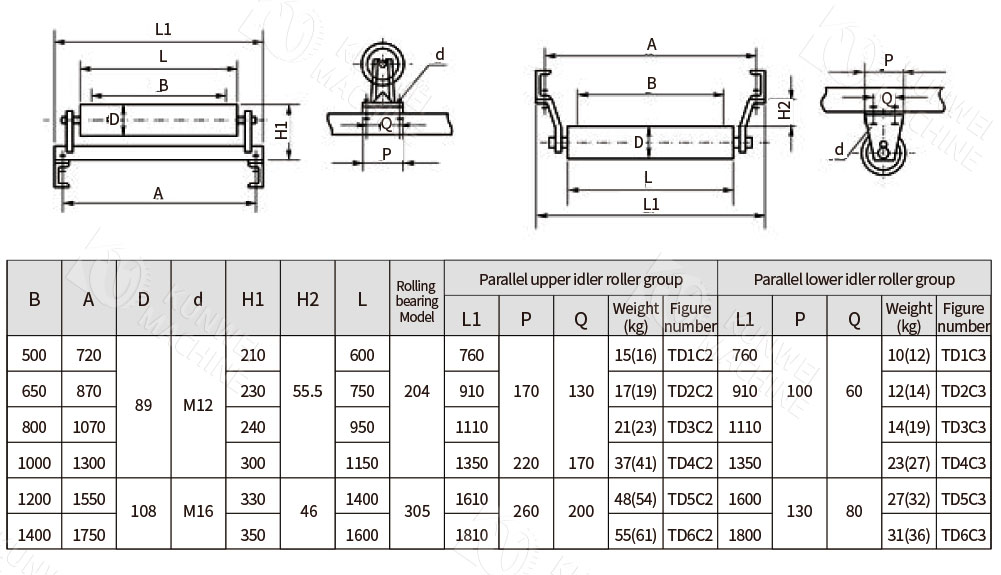

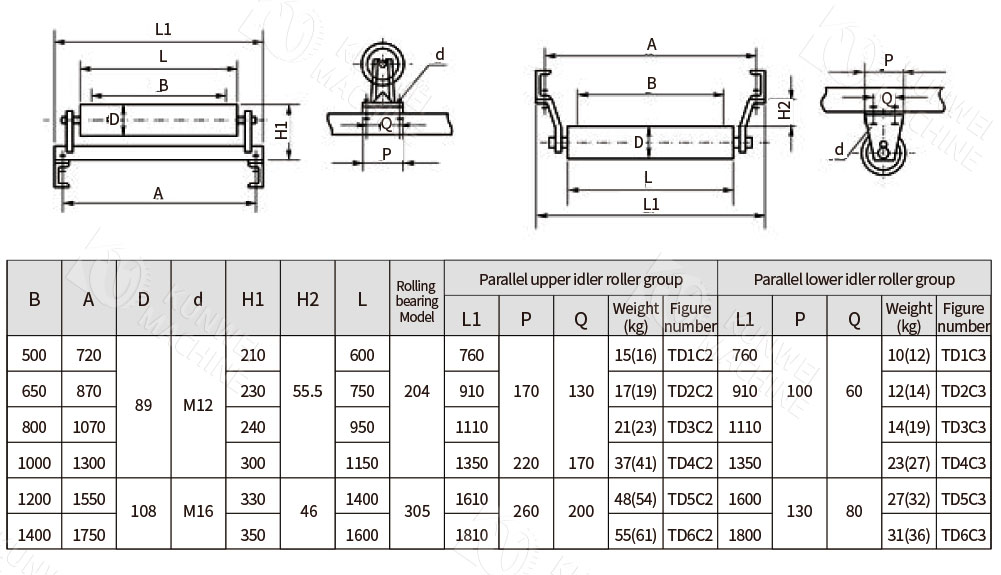

First. Introduction of parallel rollers for belt conveyor:

Parallel rollers have normal type, comb type, forward tilting type, steel rubber type, spiral type and other models. Henan Kunwei Machinery produces a full range of roller sets with excellent quality. All kinds of rollers have advanced structure and reliable performance, the materials used for roller skins are strictly selected, and high-quality special welded pipes are used with strict tolerance requirements. Shaft material adopts cold-drawn round steel, bearing seat adopts high-quality steel plate stamping, sealing structure adopts type, three sealing devices, dustproof and waterproof performance are better than the relevant national standards. The assembled rollers have good strength, small amount of longitudinal runout, low rotational resistance, light weight, low energy consumption and long service life.

Second, the belt machine parallel rollers classification:

There are many types of parallel rollers, mainly including parallel roller sets, parallel upper rollers, parallel lower rollers, parallel upper aligning rollers, parallel lower aligning rollers and so on.

1、Parallel upper rollers, parallel lower rollers: usually used in the harbor transportation terminal, mining conveyor, machinery and equipment.

2、Parallel upper centering rollers, parallel lower centering rollers: usually used to prevent belt deflection.

[contact-form-7 id="b88c0ec" title="product form"]