How to fundamentally solve the problem of belt conveyor deflection

News 2025-06-19

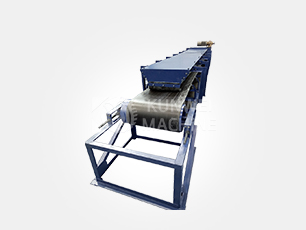

Belt machine is an important equipment for many enterprises, power plant conveying coal, petroleum coke, building materials conveying cement, sludge, quartz sand, environmental protection projects conveying water plants, garbage and so on. And in the use of belt conveyor, the problem of runaway is also a common failure, but also a big headache. If the belt conveyor runs off, it will lead to production line stoppage, which not only affects the production efficiency, but also increases the maintenance cost. Therefore, how to fundamentally solve the problem of belt conveyor deflection is very necessary.

First of all, we need to understand the causes of belt machine deflection. There are many factors that cause belt machine deflection, such as bearing failure, tape aging, drive device failure, external interference and so on. Therefore, to solve the problem of belt machine deflection, it is necessary to analyze and deal with different reasons.

First, bearing failure

Once the bearings of the belt machine have problems, it will lead to the belt machine deflection. If the bearing is damaged, it will lead to the axial displacement of the belt machine, which makes the belt running unstable. Therefore, when the bearing failure is found, it needs to be replaced or repaired in time.

Second, tape aging

Tape is a key component of the belt conveyor, and years of use will lead to tape aging. After aging, the tape will become unstable, resulting in the belt conveyor running off. Therefore, it is very important to replace the tape regularly.

Third, the drive device failure

The drive device is the core component of the belt conveyor, once the failure will lead to the belt conveyor deflection. There are many reasons for the failure of the drive device, which may be motor failure, reducer failure, coupling loosening and so on. Therefore, to ensure the normal operation of the drive device, it is necessary to regularly check and maintain.

Fourth, environmental factors

External interference is also one of the causes of belt conveyor runaway. For example, the ambient temperature is too high or too low, windy and other meteorological conditions, easy to make the belt machine run off. In addition, when the production line is spraying or cutting hazardous substances, these substances may remain on the belt, resulting in belt conveyor deflection. Therefore, try to avoid the influence of these disturbing factors.

For the above reasons, we can take the following measures:

I. Regular inspection and maintenance

For the bearings, tapes, driving devices and other key parts of the belt machine, regular inspection and maintenance should be carried out, and problems should be found and dealt with in time to prevent failures.

Second, the use of high-quality accessories

Choosing high-quality belt conveyor accessories can improve the stability and service life of the belt conveyor, and reduce the probability of the occurrence of runaway.

Third, the use of technical means

Now many companies have introduced advanced technical means, such as laser real-time detection systems, vibration detection systems, etc., these technical means can effectively predict and diagnose the deflection problem of the belt conveyor, so as to take measures to solve the problem in advance.

Fourth, strengthen training and management

For the use of belt machine workers, to carry out relevant training, strengthen safety awareness, understand how to correctly operate the belt machine. At the same time, enterprises should strengthen management, implementation of relevant systems and regulations to ensure the normal operation of the production line.

In short, the belt machine deflection is a problem that needs to be considered and solved in various aspects, for different reasons, take different measures to fundamentally solve the deflection problem. Only in this way can we ensure the normal operation of the production line, improve production efficiency and reduce maintenance costs.