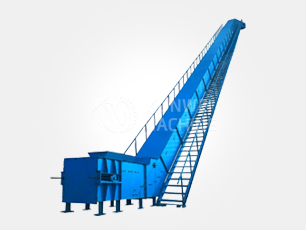

Conveying efficiency of belt conveyors

News 2025-08-07

Efficiency refers to the ratio of useful power to drive power, and it also has various extended meanings. Efficiency can be categorized into many types, such as mechanical efficiency. Efficiency is not directly related to the speed of work performed. It primarily refers to an evaluation method that assesses the most effective use of resources under specified input and technical conditions to meet predetermined objectives and needs.

How should the conveying efficiency of a belt conveyor be calculated? What factors influence its conveying efficiency? Jinrui Machinery has compiled the following five aspects, hoping they will be helpful to you.

The primary factors affecting the conveying efficiency of a belt conveyor are design selection and power calculation. The main factors influencing the power of a belt conveyor are the conveying volume and belt speed.

1. When the conveying volume q is constant, the conveyor belt power P is directly proportional to the belt speed V. Similarly, if the belt speed v increases, the power consumed to overcome resistance also increases accordingly. Therefore, by reducing the belt conveyor’s speed v, the conveyor’s energy consumption can be reduced, ultimately achieving energy-saving objectives.

2. The conveying capacity of a belt conveyor is related to production geological conditions and process equipment, and has significant uncertainty. Therefore, by studying the relationship between belt conveyor speed and filling rate, the energy consumption of the belt conveyor can be reduced. Under certain conveying capacity conditions, the lower the belt speed, the higher the material filling rate. Therefore, by reducing the belt speed, the material filling rate can be increased, thereby achieving energy-saving objectives.

III. When conveying capacity decreases, if the speed remains unchanged, energy consumption will increase. Therefore, when the conveying capacity of the belt conveyor is small, the belt speed can be selected based on design considerations.

4. As the primary transportation equipment in mines, the energy consumption of belt conveyors significantly impacts transportation costs for coal mines and other enterprises. If a constant-speed operation mode is adopted, the following issues may arise: when the conveyor is unloaded or lightly loaded, it may result in energy waste, and the friction coefficient between the machinery and the conveyor belt is relatively high.

5. To improve the transportation efficiency of conveyors and reduce energy consumption, it is necessary to take measures to adjust the belt speed of conveyors. When the conveyor’s load changes, the belt speed should be adjusted in real-time based on the load to achieve energy-saving operation and extend the conveyor’s lifespan. The conveyor belt is driven by an electric motor, and components such as the belt and drums generate resistance during operation. Typically, the main sources of resistance in a conveyor include: friction resistance between the belt and drums, compression resistance from the material, rotational resistance from the idlers, and bending and oscillation resistance from the belt.