Types of rollers corresponding to different models of belt conveyors

News 2025-08-13

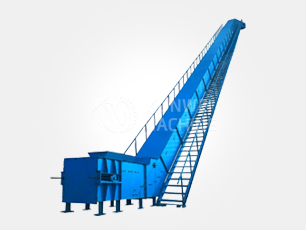

Types of idlers corresponding to different models of belt conveyors

Idlers, as important support components of conveyor belts, are indispensable accessories in belt conveyors. Do you know how many types there are? Which types correspond to which models of belt conveyors? Today, the editor from Kunwei Machinery will provide an overview of the relevant knowledge. Commonly used idlers for mining belt conveyors are divided into five types:

1. Trough-type idlers

Trough-type idlers are used for carrying bulk materials and consist of three idlers. The trough angle is generally 30 degrees, and they have a fully sealed design. Trough-type idlers can reduce the height of the idler frame and decrease the equivalent idler group spacing, making them suitable for areas with lower belt stiffness and limited space.

2. Buffer Rollers

Buffer rollers are installed at the material discharge point of the conveyor to mitigate the impact of falling materials on the conveyor. They possess high toughness, corrosion resistance, flame retardancy, and static dissipation properties, and are widely used in mining operations.

3. Self-aligning Idler Rollers

Self-aligning idler rollers correct excessive belt deviation during operation, preventing belt serpentine movement to ensure stable belt operation. In conveyors requiring self-aligning idler rollers, one set is typically installed every ten idler roller groups.

4. Return Idler Rollers

Return idler rollers are the most commonly used type of lower idler rollers. For large conveyors, two rollers can be used, arranged in a V-shape to prevent deviation and provide higher load-bearing capacity. Most designs involve installing three sets of V-shaped and V-shaped inclined lower idler rollers consecutively every seven sets of parallel lower idler rollers.

5. Transition Idlers

Transition idlers are suitable for high-capacity, long-distance conveyors with high belt tension and critical applications. Transition sections should generally be installed, where transition idlers are arranged.

The above is a detailed classification of idlers. Which type of idler corresponds to each model of belt conveyor? Based on their shape, they are generally divided into two types: trough-type (U-shaped, V-shaped) idlers and parallel idlers. Of course, specific equipment customization should be determined based on actual conditions.

For steep-angle belt conveyors using corrugated sidewall conveyor belts, the load-bearing idlers are parallel idlers. Depending on actual conditions, side guides may be added on both sides to prevent issues such as belt deviation. For TD75 or DTII-type belt conveyors, which use chevron belts or patterned belts, both types of idler rollers can be used. Generally, trough-type rollers are more common for bulk material conveyance, with the choice between U-type or V-type rollers depending on factors such as handling capacity; parallel idler rollers are typically used for bagged materials.