How to distinguish between heavy-duty belt conveyors and light-duty belt conveyors

News 2025-08-21

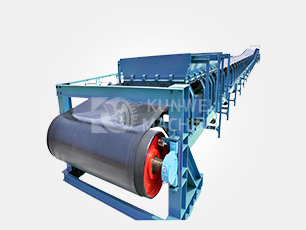

Henan Kunwei Machinery specializes in heavy-duty mining belt conveyors. However, some customers may wonder why we can produce heavy-duty conveyors but not lightweight ones. In reality, the applicability of materials and structural designs is not as straightforward as one might imagine. The following are the main factors that distinguish between the two types.

1. Material

Heavy-duty belt conveyors typically transport industrial bulk materials or bagged materials such as coal, ore, coke, and coal ash.

Light-duty belt conveyors typically transport agricultural bulk materials or bagged materials such as grain, straw, feed, and food products.

2. Belt Width

Heavy-duty belt conveyors typically have belt widths of 400, 500, 650, 800, 1000, 1200, or 1400 mm.

Light-duty belt conveyors typically have belt widths of 100, 150, 200, 250, 300, 400, 500, or 600 mm.

III. Conveyor Belt (Rubber Belt)

Heavy-duty belt conveyors use black rubber belts made of nylon (NN), cotton canvas (CC56), or polyester (EP) materials.

Light-duty belt conveyors can use white or green PVC or PU materials for their conveyor belts.

4. Structure

Heavy-duty belt conveyors, specifically the large-angle belt conveyors, primarily consist of corrugated sidewall belts, electric drums, redirecting drums, belt tensioning wheels, idler rollers, spiral tensioning devices, cleaners, head frames, head hoppers, head guards, material guide chutes, intermediate frames, tail frames, legs, and drive frames.

Light-duty belt conveyors have an overall structure primarily composed of tensioning devices, power units, and support frames.