How to Fundamentally Resolve Belt Conveyor Misalignment Issues

News 2025-08-27

How to Fundamentally Solve Belt Conveyor Misalignment Issues

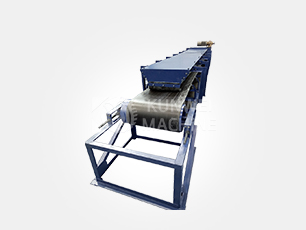

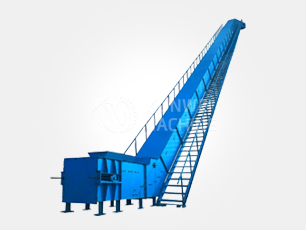

Belt conveyors are critical equipment for many enterprises. Power plants use them to transport coal and petroleum coke, while construction material plants convey cement, sludge, and quartz sand. Environmental projects utilize them to move aquatic plants, waste, and other materials. During operation, misalignment is a common yet troublesome failure. If a belt conveyor becomes misaligned, it can halt production lines, impacting efficiency and increasing maintenance costs. Therefore, fundamentally resolving belt conveyor misalignment is essential.

First, we must understand the causes of belt conveyor misalignment. Numerous factors contribute to this issue, including bearing failure, belt aging, drive system malfunctions, and external interference. Thus, addressing misalignment requires analyzing and treating each specific cause.

I. Bearing Failure

Bearing issues can immediately cause belt deviation. Damaged bearings lead to axial displacement of the conveyor shaft, resulting in unstable belt operation. Therefore, bearings must be promptly replaced or repaired upon detection of failure.

II. Belt Aging

The belt is a critical component of the conveyor. Long-term use causes the belt to age. Aged belts become unstable, causing the conveyor to drift. Regular belt replacement is therefore crucial.

III. Drive System Malfunction

The drive system is the core component of the conveyor. Any failure here will cause drifting. Drive system malfunctions can stem from various causes, including motor failure, reducer failure, or loose couplings. To ensure proper drive system operation, regular inspection and maintenance are essential.

IV. Environmental Factors

External disturbances also contribute to belt deviation. For instance, extreme temperatures (too high or too low) and strong winds can easily cause the belt to drift. Additionally, when harmful substances are sprayed or cut on the production line, residues may adhere to the belt, leading to deviation. Therefore, minimizing the impact of these disruptive factors is essential.

To address the above causes, the following measures can be implemented:

I. Regular Inspection and Maintenance

Key components such as bearings, belts, and drive units should undergo routine inspection and maintenance. Issues must be promptly addressed to prevent failures.

II. Use of High-Quality Components

Selecting premium conveyor belt components enhances stability and service life, reducing the likelihood of misalignment.

III. Implementation of Technical Solutions

Many enterprises now employ advanced technologies like laser real-time detection systems and vibration monitoring systems. These tools effectively predict and diagnose belt deviation issues, enabling proactive corrective actions.

4. Strengthen Training and Management

Operators must receive specialized training to enhance safety awareness and master proper conveyor operation. Concurrently, companies should reinforce management protocols, enforce relevant regulations, and ensure uninterrupted production line operations.

In summary, conveyor belt deviation is a multifaceted issue requiring comprehensive consideration and resolution. Addressing the root causes with tailored measures is essential to fundamentally eliminate deviation. Only through such an approach can production lines maintain stable operation, enhance efficiency, and reduce maintenance costs.