Why does the conveyor belt on a belt conveyor keep getting damaged by friction?

News 2025-09-18

First, let’s understand the types of conveyor belts commonly used for transporting heavy materials like coal and gypsum.

Rubber belts are the primary choice, with their cores primarily categorized into four types:

1. Steel cord core;

2. Nylon belt (NN belt);

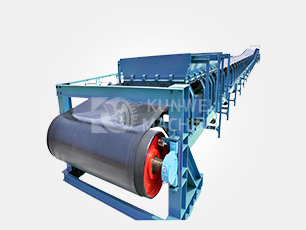

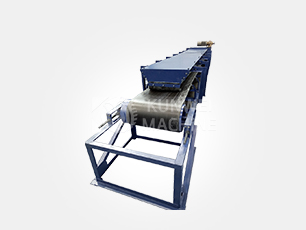

3. Cotton canvas belt (CC56); 4. Polyester (EP). Our company’s belt conveyors, such as steep-angle belt conveyors, utilize conveyor belts with corrugated sidewalls and partitions. TD75 and DTII models commonly employ flat belts or herringbone anti-slip belts. All these belts are made from the aforementioned materials, offering superior wear resistance and durability.

In reality, numerous factors contribute to friction-induced damage in conveyor belts.

1: Poor belt quality may be a contributing factor.

Nylon/cotton canvas/polyester belts are standard types. These conveyors are widely used in industrial, mining, and transportation sectors for transporting various solid bulk materials, powdered substances, or packaged goods. They enable continuous, high-efficiency, steep-angle transportation. Conveyor belts offer safe operation, simple handling, easy maintenance, low freight costs, reduced transport distances, lower engineering expenses, and savings in labor and resources.

2: Belt misalignment can also cause conveyor belt damage.

Misalignment causes are primarily categorized into three types: ① The drive roller at the head or the deflection roller at the tail is not perpendicular to the conveyor centerline, causing the belt to misalign at these points. ② Variations in roller diameter due to machining errors, material buildup, or uneven wear cause the belt to drift toward the larger diameter side. ③ Improper material drop position at transfer points significantly impacts belt deviation, especially when the projection of the upstream conveyor onto the horizontal plane is perpendicular to the downstream conveyor.

3: Incorrect material selection requires tailored belts for different goods.

For instance, our company primarily handles materials like slag and coal, predominantly using rubber belts such as high-strength, highly resilient nylon belts or canvas belts. Other lightweight belt conveyors commonly employ polyvinyl chloride (PVC) and PU belts. However, conveying sharp or angular objects can cause friction damage. In such cases, it is still advisable to consider using suitable rubber conveyor belts.