Can oil-contaminated sludge be transported via a belt conveyor?

News 2025-10-10

The transportation of oil-contaminated sludge primarily occurs at solid waste or hazardous waste treatment sites, where oil content varies significantly—ranging from 10% to 35% in higher cases, with some samples reaching as high as 50%.

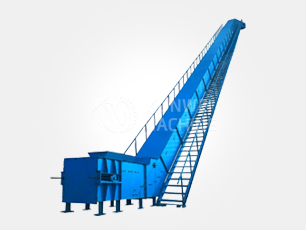

As is widely known, conveying sludge via belt conveyors is generally feasible. However, transporting sludge with excessive moisture content requires careful consideration of material stickiness—let alone the oil-contaminated sludge discussed here, which exhibits even higher viscosity.

Yet if you ask whether oil-contaminated sludge can be conveyed by belt conveyors, my answer is: Absolutely! But this depends on the specific conditions at the conveying site. If the sludge sticks to the belt upon loading and fails to discharge, belt conveyors become unsuitable. After all, our goal is to transport the material to its next destination.

Additionally, the conveying angle and elevation must be considered. Different belt conveyor types significantly impact conveying outcomes and the intended operational goals at the site.

One more tip: if a belt conveyor isn’t feasible, consider a shaftless screw conveyor. Its design makes it particularly suited for handling highly viscous materials.

Of course, the final decision depends on your specific site conditions. What material are you looking to transport? Feel free to leave a comment for assistance with selecting the right equipment!