Characteristics of different conveyor unloading equipment

News 2025-04-21

Commonly used belt conveyor unloading equipment are reversible belt conveyor, plough unloader and travelling belt tripper, three ways have their own advantages and disadvantages.

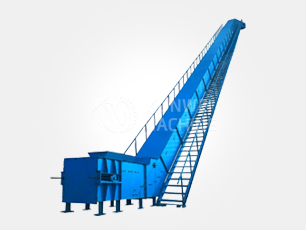

1, reversible belt conveyor

The reversible belt conveyor is generally used for bin top batching, distributing the same material to several bins, or distributing and discharging several raw materials to one or several designated bins. Reversible mobile belt conveyor can maximize the volume of silo or storage yard because of its forward and reverse head and tail discharge, and can move longitudinally for continuous discharge.

Disadvantages: not suitable for long-distance conveying, and the concentricity of the walking wheels cannot be guaranteed when conveying over long distances.

Advantages: the discharge point can be moved to realize continuous multi-point discharge; two-way operation to realize two-way discharge; the height of the whole machine is reduced, which is applicable to the occasions where the discharge truck cannot be used. The space occupied is smaller, which reduces the cost of civil construction.

2, plough unloader

The plough unloader is a loading and unloading machine used on the belt conveyor for blocking and shunting and controlling the unloading flow. The plough unloader is used to unload the material at any point of the horizontal section of the belt conveyor. Plough unloaders are available in single and double side discharge forms.

Advantages: fixed point discharge, low cost; space saving position;

Disadvantages: serious wear and tear on the belt; the material will not be unloaded cleanly because the gap between the belt and the scraping plane under the unloading plough cannot be adjusted.

3, travelling belt tripper

Travelling belt tripper is a walking cart for unloading material at any point in the middle of the belt conveyor. It is composed of frame, two rollers and guide funnel. The material is thrown out by the upper roller of the travelling belt tripper and then unloaded to one or both sides of the conveyor by the guide funnel.

Advantages: multi-point unloading, suitable for long-distance conveying; low cost, easy maintenance;

Disadvantages: it takes up a lot of space and has a heavy structure.