Product

DTII type belt conveyor

First. DTII type belt conveyor product introduction: DTII type belt conveyor is a general-purpose series of products, which is a continuous conveying equipment with cotton canvas, nylon, polyester canvas and steel wire rope core conveyor belt as the

First. DTII type belt conveyor product introduction:

DTII type belt conveyor is a general-purpose series of products, which is a continuous conveying equipment with cotton canvas, nylon, polyester canvas and steel wire rope core conveyor belt as the traction member.

DTII belt conveyor is mainly used for material transportation in mining, metallurgy, chemical industry, power plant and other industries; DTII belt conveyor has large conveying capacity, relatively simple structure, easy to maintain, interchangeability of main parts and strong generality. The permissible lumpiness of the material conveyed by the conveyor depends on the bandwidth, belt speed, trough angle and inclination angle. When conveying hard rock, after the bandwidth exceeds 1200mm, it should generally be limited to 350mm, and cannot be increased with the growth of bandwidth.

The working environment temperature is generally -5℃-40℃. For places with special requirements, such as high temperature, cold, explosion-proof, flame retardant, corrosion-proof, acid and alkali resistant, waterproof and other conditions, corresponding protective measures should be taken.

DT Ⅱ type belt conveyor are designed according to component series. When selecting, it can be designed, calculated and assembled as a complete set according to the process route, different terrain and working conditions. Manufacturing plant according to the general drawing or parts list production, supply. The conveyor should be installed in the through corridor as far as possible. In the open air, the driving station should be covered with protective cover.

This series of products can meet the conditions of horizontal, lifting and downward transportation. It can also adopt the conveying form with convex arc section, concave arc section and straight line section combination.

Second, DTII type belt conveyor product advantages and features:

1,Simple structure. The structure of belt conveyor produced by Henan Kunwei Machinery mainly consists of several major components such as drive roller, redirecting roller, carrier roller, driving device, braking device, conveyor belt and so on. Its components are few, universal, easy for standardized production, and can be combined and assembled as needed, and because of the simple structure, reliable operation, high efficiency, easy to realize automation.

2,Wide range of conveying materials. The conveyor belt of the belt conveyor can be manufactured according to the characteristics of the conveyed objects into conveyor belts with various performance requirements such as anti-abrasion, flame retardant, corrosion resistance, high and low temperature resistance, and thus can convey all kinds of bulk materials, block materials, chemicals and concrete, etc.

3,Large conveying capacity. Capacity can be from a few tons per hour to several thousand tons, and is continuous uninterrupted delivery, which is unmatched by other transport equipment.

4,Long transportation distance. The length of a single machine can be up to 1,000 meters, which has been very popular in foreign countries, and there is no need for any transfer point in the middle. When the use of intermediate friction drive mode, the length of the conveyor can be greatly increased, theoretically not subject to the limitations of the strength of the conveyor belt.

5, loading and unloading material is very convenient. The belt conveyor can be loaded and unloaded at any point according to the needs of the production process, and can also be loaded and unloaded on the return section for reverse transportation.

6,High reliability. Due to the simple structure and light weight of moving parts, as long as the conveyor belt is not damaged, the life is relatively long; metal structural parts, as long as the rust-proof is good, it is not easy to be damaged; wear parts of the rollers are damaged, the replacement and maintenance is more convenient and quick.

7, low energy consumption, high efficiency. Due to the light weight of the moving parts, less invalid capacity, in all continuous and non-continuous transportation, the belt conveyor has the lowest energy consumption and the highest efficiency.

8,Strong adaptability, wide range of applications, can save a lot of infrastructure investment.

Third, the scope of application of DTII belt conveyor:

DTII belt conveyor has the advantages of large conveying capacity, simple structure, convenient maintenance, standardization of components, etc. It is widely used in mining, metallurgy, coal and other industries for conveying loose materials or pieces of goods, and according to the requirements of conveying process, it can be conveyed by a single conveyor, or composed of more than one unit, or formed with other conveying equipment to form a horizontal or inclined conveying system, in order to meet the needs of different arrangements of the line of operation. For the working environment of heat-resistant, cold-resistant, anti-corrosion, anti-drying and flame retardant requirements, special rubber conveyor belts and protective measures can be used. Its length and assembly form can be determined according to the user’s requirements, the drive can be used for electric roller, can also be used with the drive frame of the drive device.

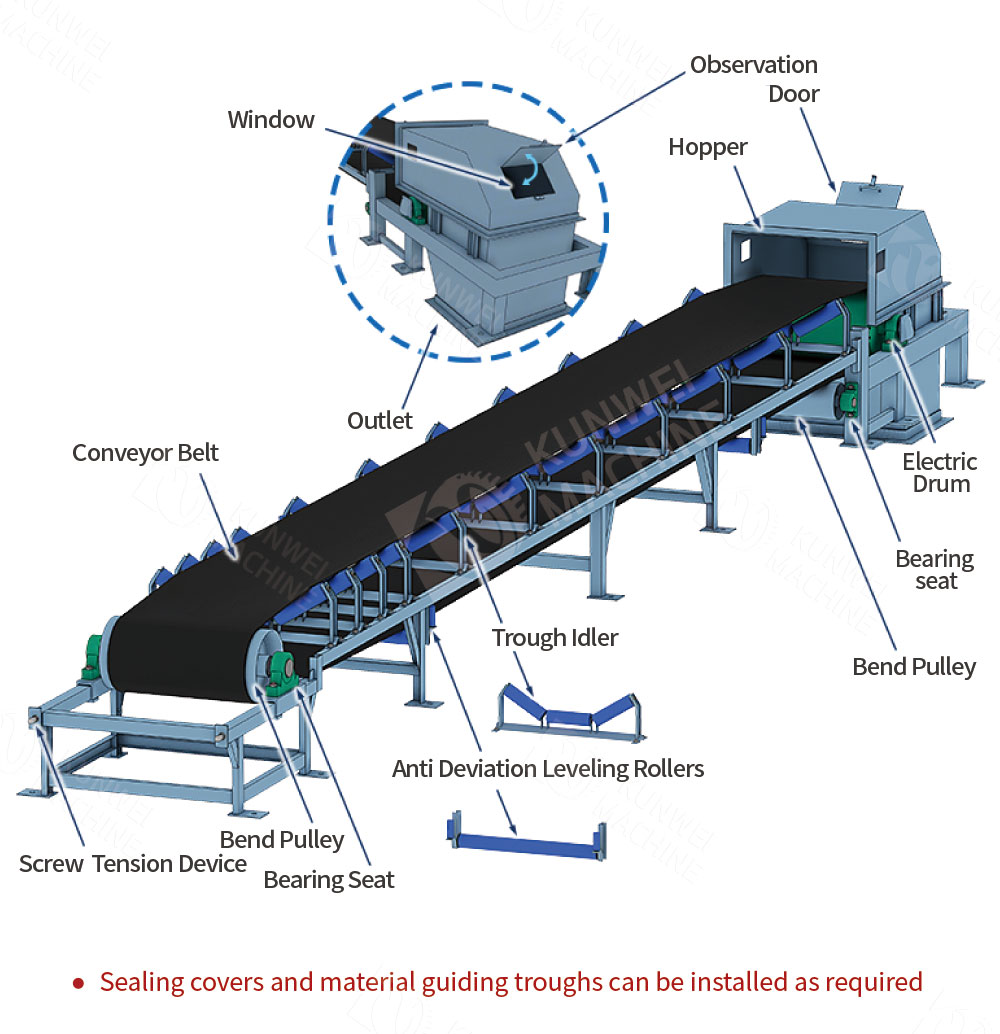

Fourth.DTII type belt conveyor structure composition:

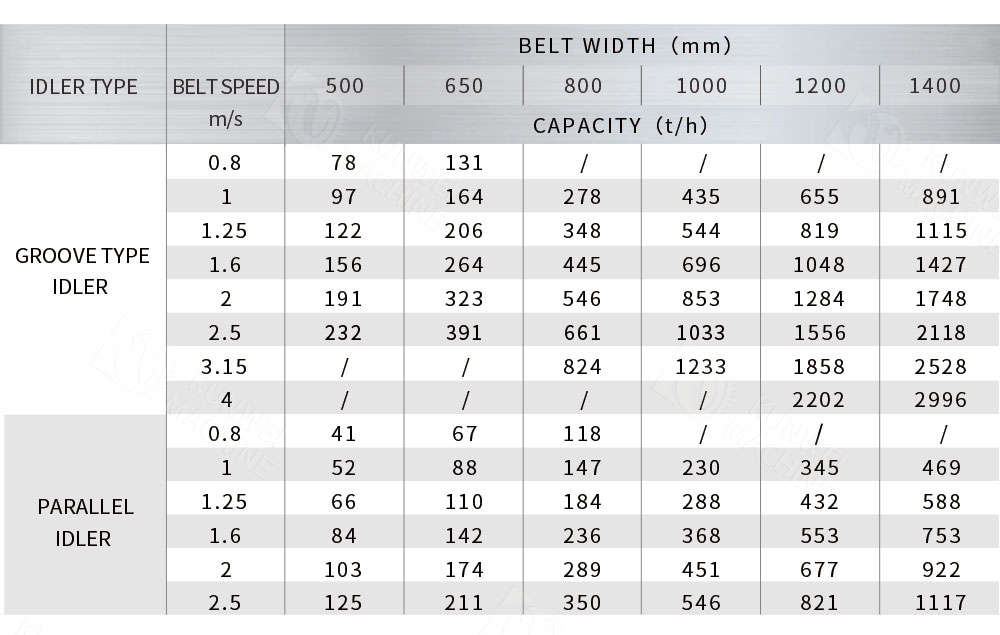

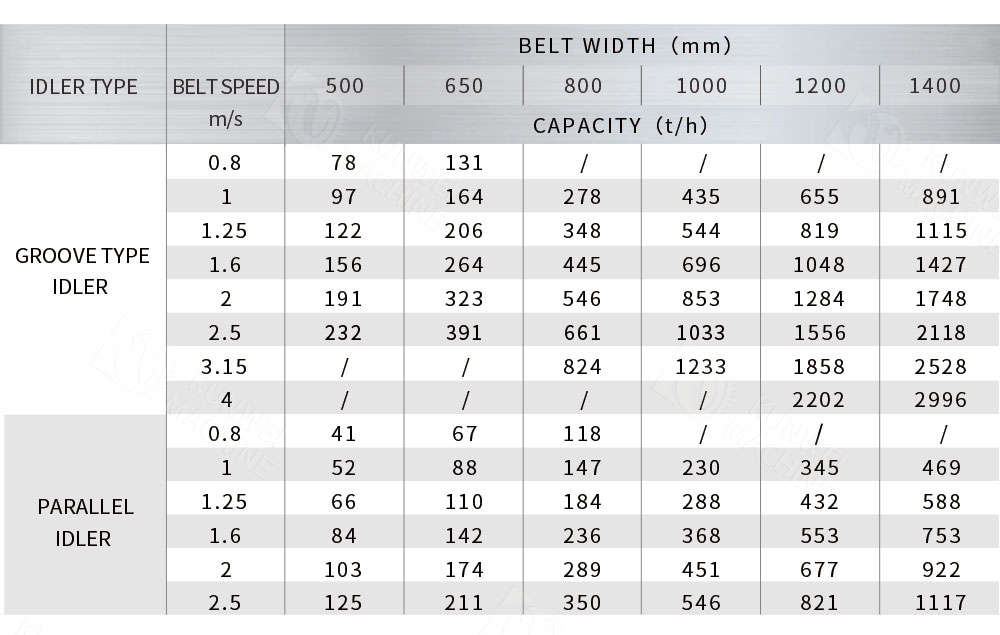

Fifth. Parameters of DTII belt conveyor:

DTII belt conveyor conveyor belt is connected into a closed ring, with tensioning device to tension them, under the drive of electric motor, by the friction between the conveyor belt and the driving rollers (or driving wheels), make the conveyor belt run continuously, so as to achieve the purpose of transporting the cargo from the loading end to the unloading end.