First, the belt machine unloading trolley product introduction.

Belt machine unloading trolley belongs to one kind of unloading device, which can unload material at any point in the horizontal section of the belt machine, convenient for the overall fabric. Because of the steel rail, can be easily moved, the material with the unloading car angle to lift a certain height, through the three-way or two-way to realize the two sides or one side of the unloading, the flow of materials and the flow of each way through the gate valve (or flap valve) control. Belt conveyor unloading trolley belongs to a separate part of the belt conveyor, mainly used in the belt conveyor unloading requirements of the occasion. Its role is the same as the unloader, but can realize the multi-point fabric and different locations of the fabric. More convenient to use, but relatively high cost, suitable for use in large belt conveyor.

Second, the belt conveyor unloading trolley product features advantages.

1, the unloading point can be moved to realize long-distance continuous multi-point unloading.

2, unloading trolley single or double side can be unloaded.

3, not subject to unloading bin limitations, more suitable for large unloading sites.

Third, the belt machine unloading trolley scope of application:

Belt machine unloading trolley due to its longitudinal movement of continuous unloading characteristics, can maximize the use of silo or storage yard volume, is widely used in metallurgical plants, electric power, chemical plants, and coal and other industries.

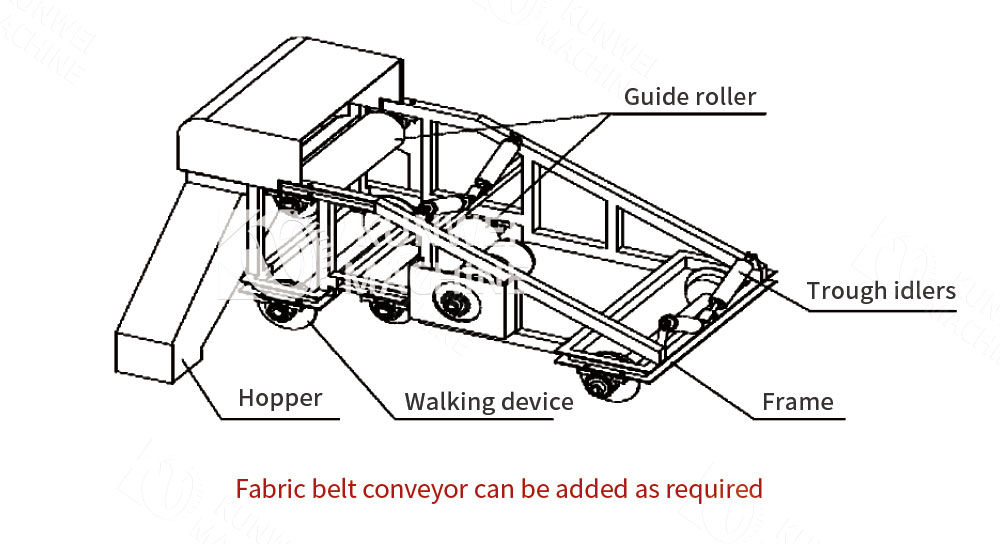

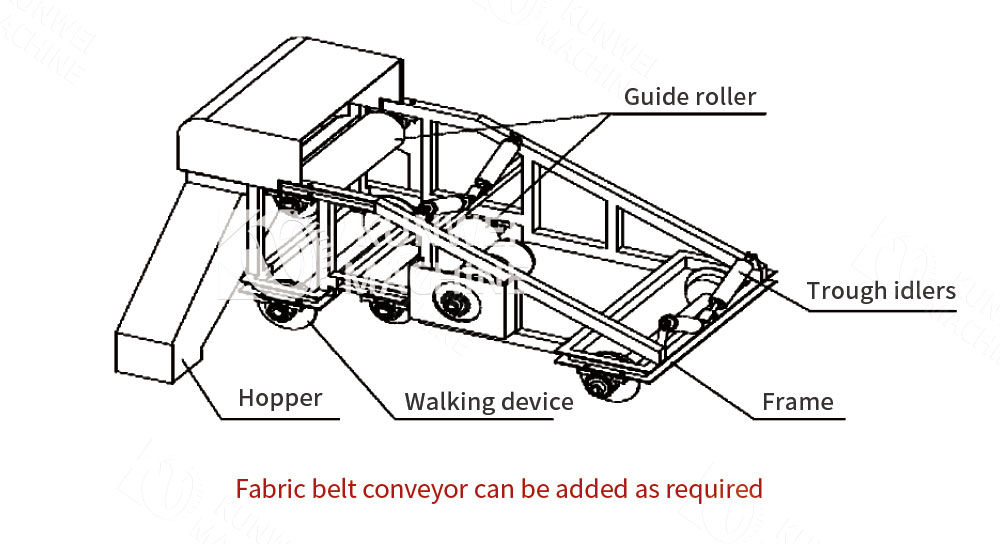

Fourth, the belt machine unloading trolley structure composition.

1, traveling light rail. Walking light rail is set up in the conveyor above, as walking steel wheel support and running track use.

2, receiving hopper. The material is transported to the receiving hopper by the conveyor belt, and then deposited and dispersed to the chute.

3. Chute. Like all the head chutes, the chute of the unloading trolley includes double-side unloading and single-side unloading.

4、Walking drive structure. The unloading trolley can move by itself, so it needs to install the traveling drive structure. Walking drive structure consists of motor reducer.

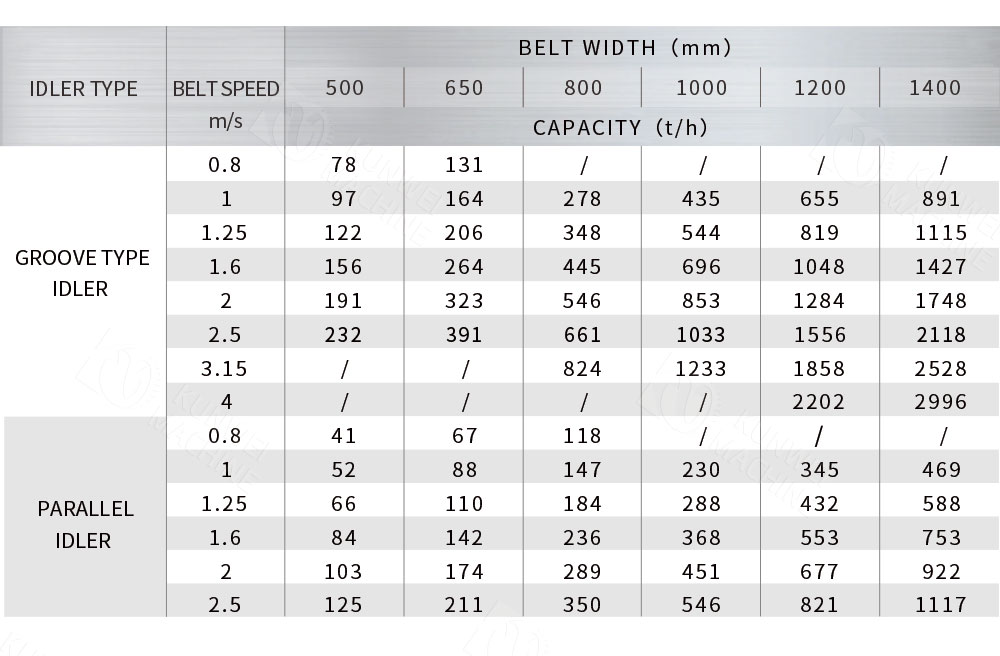

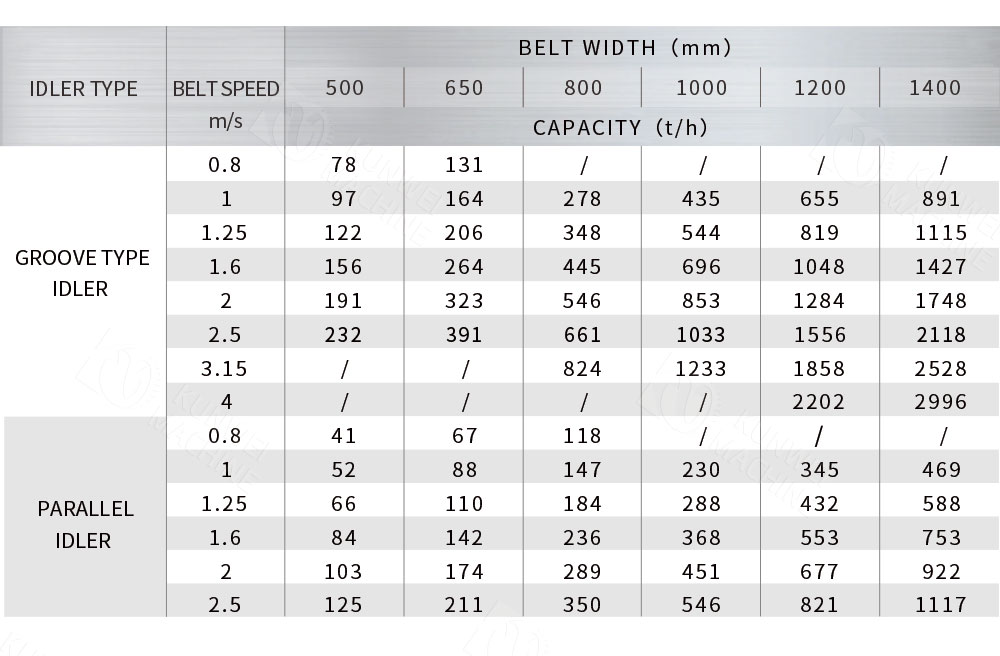

Fifth. Belt machine unloading trolley technical parameters.

[contact-form-7 id="b88c0ec" title="product form"]