First. Introduction of mobile belt conveyor:

Mobile belt conveyor is a kind of continuous conveying and loading and unloading equipment with high work efficiency, safe and reliable use and good mobility. Mainly used for loading and unloading place often change the place, such as: port, dock, station, coal yard, warehouse, construction site, etc., used for short-distance transportation and loading and unloading of bulk materials or single piece of weight of 100 kg or less of the piece of goods.DY-type mobile belt conveyor is divided into lifting and non-lifting type of two major types of conveyor belt operation by the motorized pulley drive.

The mobile belt conveyor is suitable for short-distance transportation and loading/unloading of bulk materials or pieces of goods. It adopts steel tube structure, which is light and beautiful with good maneuverability. The rotating device is motorized pulley and equipped with two kinds of walking wheels: pneumatic tire and universal wheel. The length of the machine is more than 10 meters and the tilting angle is adjustable.

Mobile belt conveyor produced by Henan Kunwei Machinery is a kind of conveying equipment used in industrial and mining, mobile belt conveyor is easy to use, good maneuverability, in the industrial and mining industry has been favored by many users and praise.

Second. the main features of the mobile belt conveyor advantages:

1, mobile belt conveyor applicable site is not limited, whether indoor or outdoor, how to waterproof requirements, you can use color steel tiles for closed processing.

2, good mobile performance, can be moved by traction; good throughput, can be directly for loading operations, material transfer and other occasions.

3, easy to operate, the machine is equipped with a control box, including a main control switch, a lift switch. However, it still needs to be manually guarded to avoid accidents.

Third, mobile belt conveyor applicable scope:

It can be used for horizontal transportation or inclined transportation, which is very convenient to use and widely used in various modern industrial enterprises, such as: mine ground transportation system, open-pit mining field and ore dressing plant. According to the requirements of conveying process, it can be used for single conveyor, or can be composed of multiple units or with other conveying equipment to form a horizontal or inclined conveying system, in order to meet the needs of different layout forms of the operating line.

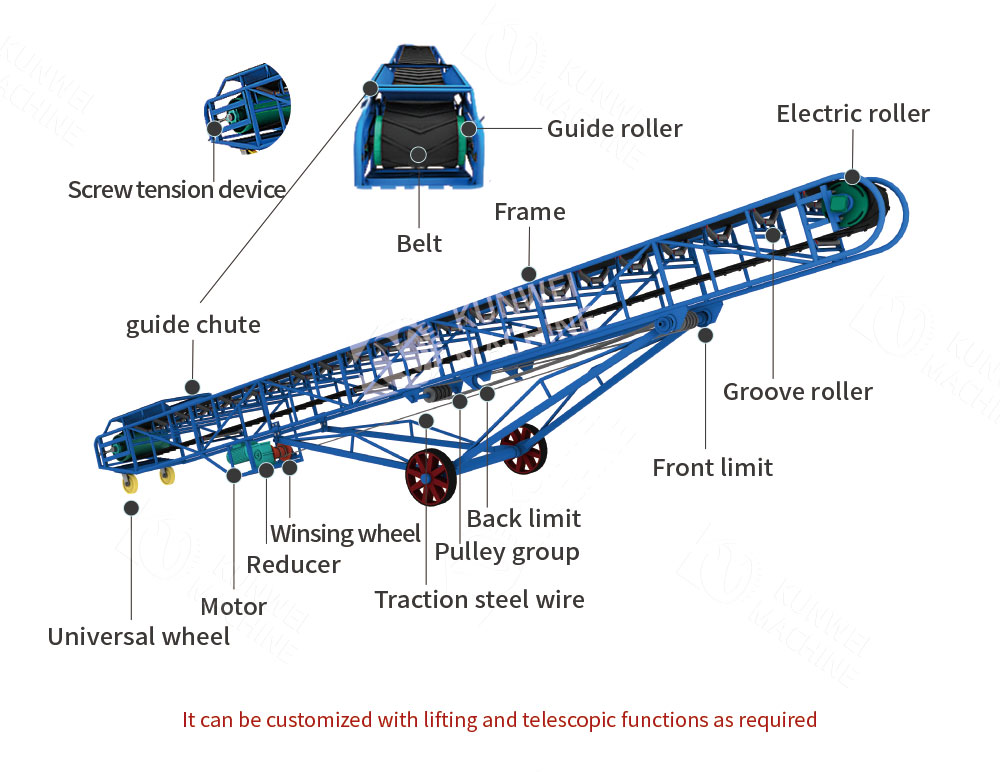

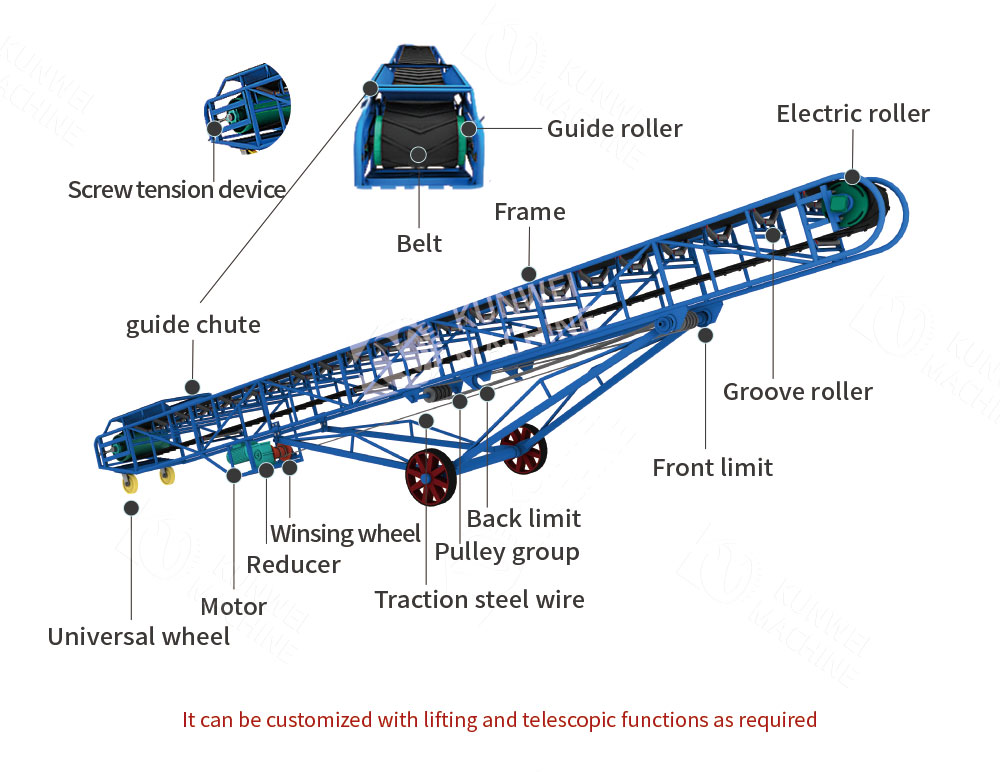

Fourth, mobile belt conveyor structure composition:

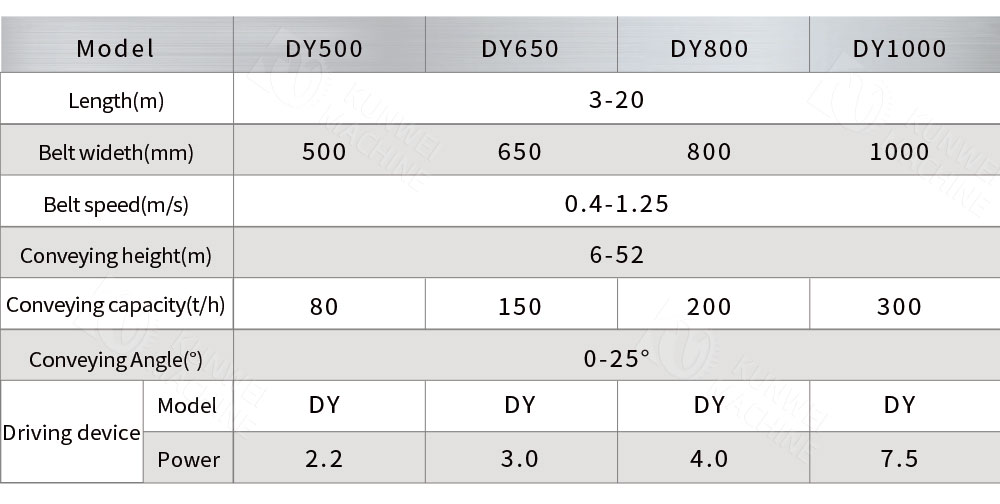

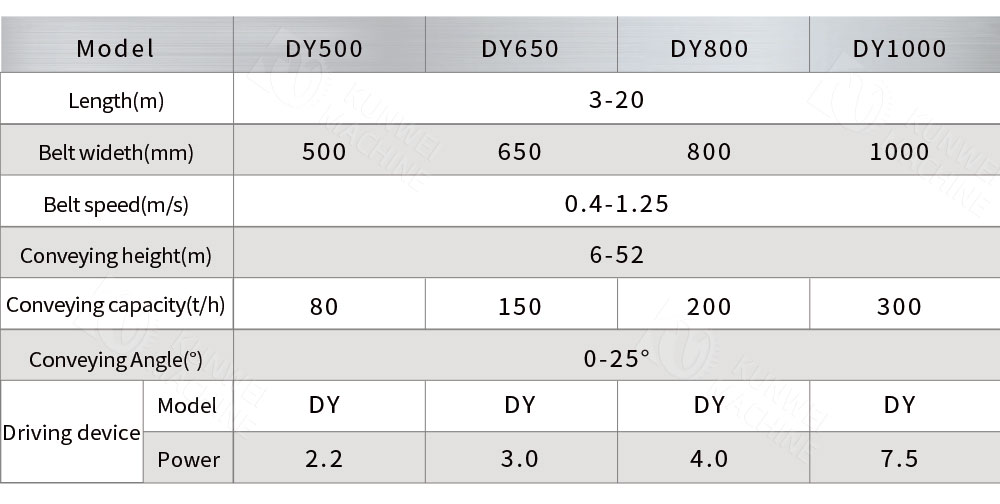

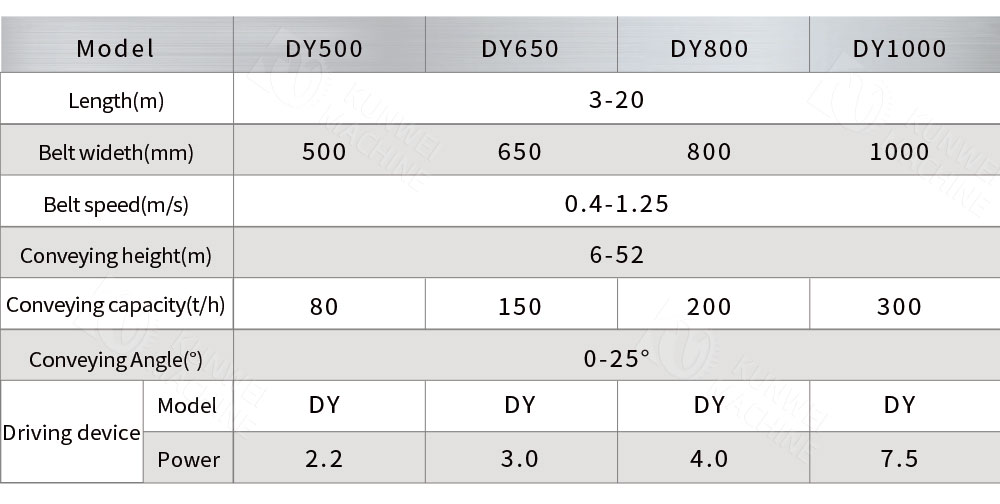

Fifth, mobile belt conveyor equipment technical parameters:

Generally according to the requirements of the material handling system, material loading and unloading location of the various conditions, the production process and the characteristics of the material to determine the main parameters.

1, conveying capacity: conveyor equipment conveying capacity refers to the amount of material conveyed per unit of time. When conveying bulk materials, the quality or volume of materials conveyed per hour; when conveying pieces of goods, the number of pieces conveyed per hour.

2、Conveying speed: Increasing conveying speed can improve conveying capacity. In the conveyor belt for traction and conveying a larger length, the conveying speed increases day by day. However, high-speed operation of the belt conveyor need to pay attention to vibration, noise and start, braking and other issues.

3, the size of the components: the size of the components of the conveyor, including the width of the conveyor belt, the width of the slats, the volume of the hopper, pipe diameter and the size of the container and so on.

4, conveying length and inclination: the length of the conveyor line and the size of the inclination directly affects the total resistance of the conveyor and the power required.