First. gx screw conveyor product introduction:

The gx screw conveyor is commonly known as the winch, is a widely used conveying equipment in the mineral, chemical and construction industries, from the point of view of the direction of the displacement of the transported material, the gx screw conveyor is the use of rotating spiral will be transported along the fixed casing of the material to be pushed for transport work, the head and tail bearings are moved outside the casing, the hanging bearing adopts the sliding bearing is equipped with a dust sealing device, the axle tile is generally powder metallurgy, conveying cement adopts felt axle tile, the hanging shaft and the screw shaft adopts the slider connection. The head and tail bearings are moved outside the casing, and the hanging bearing adopts sliding bearing with dustproof sealing device. Screw conveyor is divided into two types: horizontal screw conveyor and vertical screw conveyor, which is mainly used for horizontal conveying and vertical lifting of various loose materials such as powder, granule and small block. The standardized screw diameters are: 150mm; 200mm; 250mm; 300mm; 400mm; 500mm; 600mm.

Second, gx screw conveyor product features advantages:

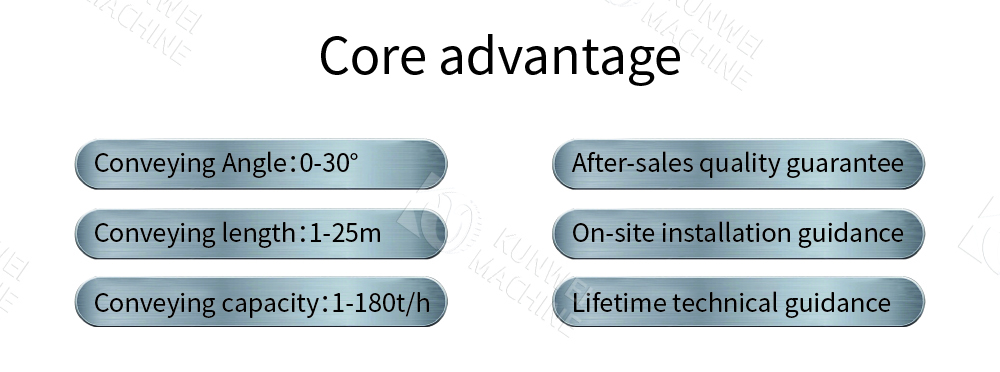

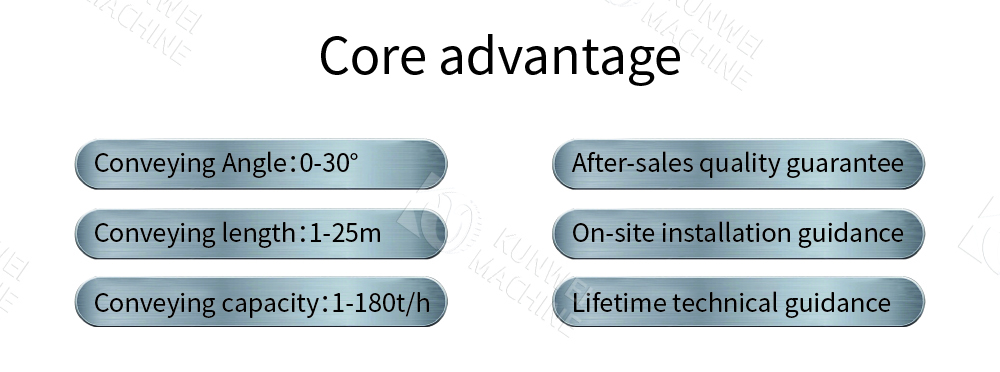

Compared with other conveying equipment, gx screw conveyor has the features of simple structure, small cross-section size, good sealing performance, etc. It can be loaded and unloaded in the middle multi-points, and the operation is safe and convenient as well as the manufacturing cost is low. Specific features are as follows:

1, large bearing capacity, reliable.

2、Strong adaptability, easy installation and maintenance, long life.

3、Small size of the whole machine, high speed to ensure fast and uniform transportation.

4、The discharge end is equipped with a cleaning device, low noise of the whole machine, strong adaptability, flexible arrangement of the position of the inlet and outlet.

5、Good sealing, the shell is made of seamless steel pipe, and the ends are connected with each other by flanges, with good rigidity.

Third, gx screw conveyor application scope:

gx screw conveyor is a kind of screw conveying equipment widely used in chemical industry, building materials, metallurgy, mining and other departments, mainly used for conveying powdery, granular and lumpy materials with small degree.

gx screw conveyor is suitable for conveying small granularity and powdery materials, not suitable for conveying easily deteriorated, viscous and easily caked materials. The working temperature is -20℃-50℃. Conveying angle is not more than 20 °, conveying material temperature is 2 ℃ below, the length of the machine is 3-70m.

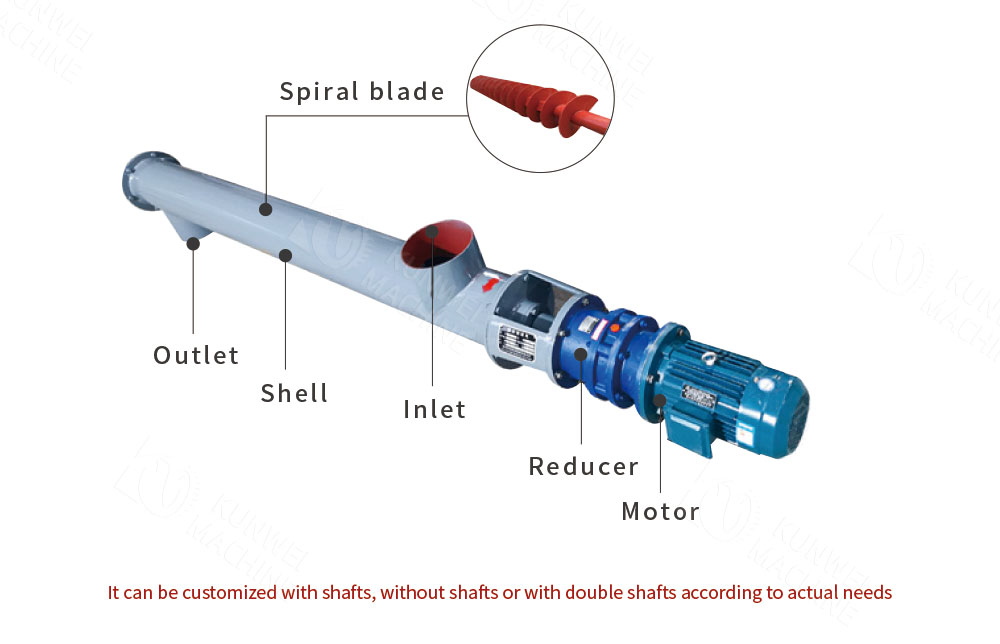

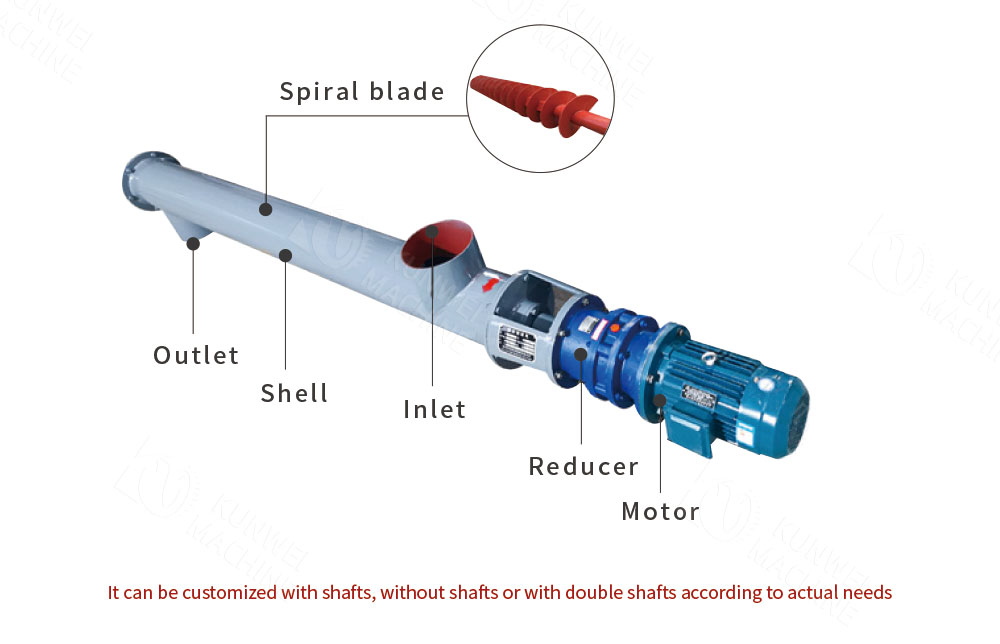

Fourth, gx screw conveyor structure composition:

The installation structure of gx screw conveyor can be divided into three parts: head section, middle section and tail section. The length of these three sections is set according to the user’s demand, so as to form a complete GX screw conveyor. If it is fixed horizontally on the ground, the ground needs to be reserved with feet and expansion wire holes for fixing. In case of angular conveying, the corresponding support must be set beforehand.

GX screw conveyors are also divided into two types according to the method of driving the unit: right and left mounting. Right-mounted – standing in the motor tail section and looking forward, the reducer low-speed shaft is on the right side of the motor; left-mounted – standing in the motor tail section and looking forward, the reducer low-speed shaft is on the left side of the motor.

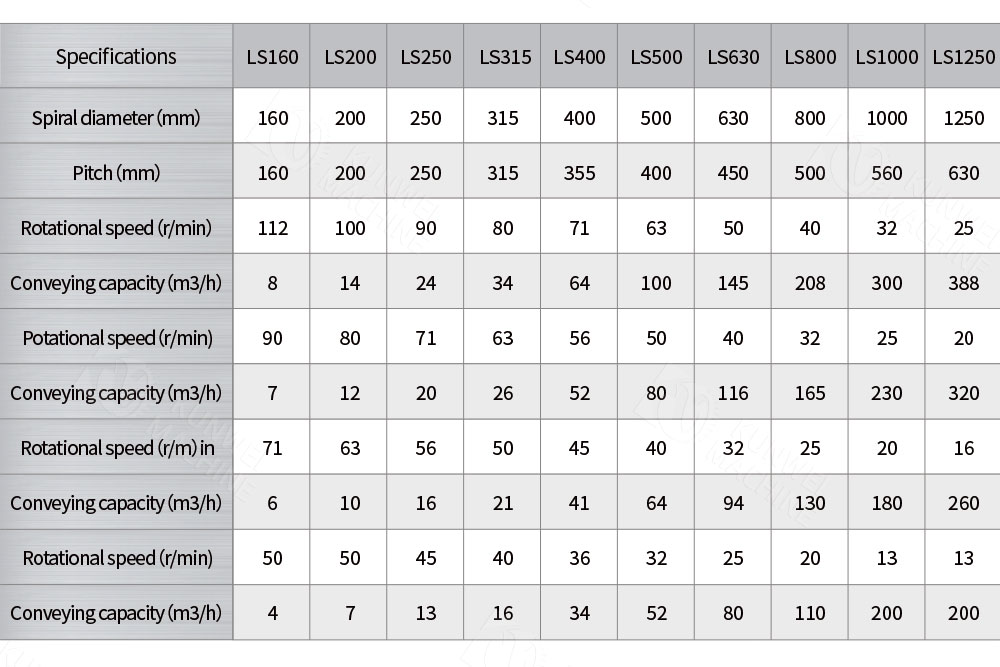

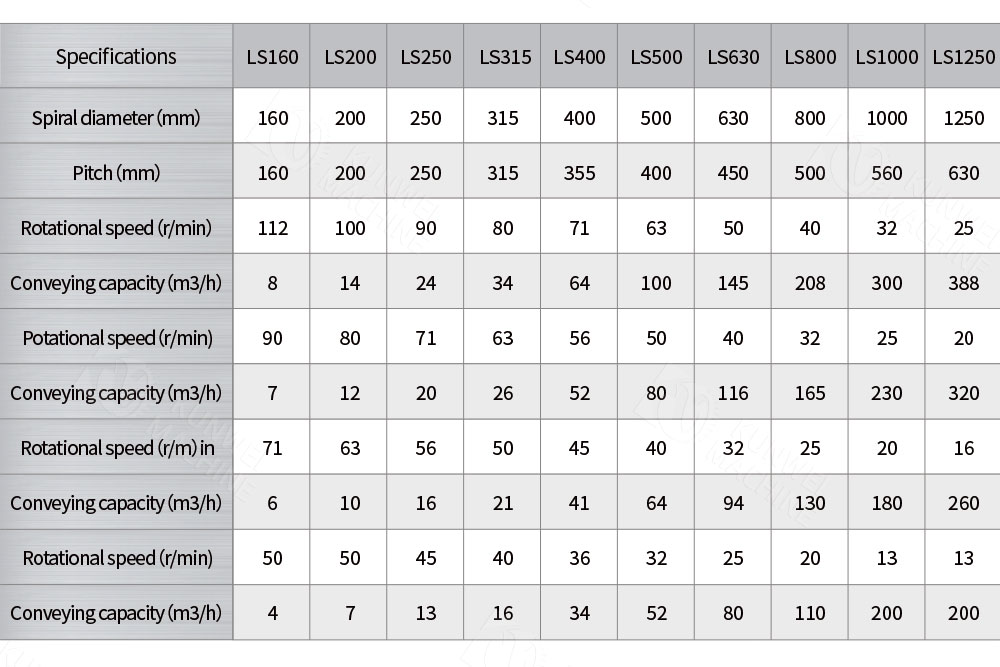

Fifth. gx screw conveyor technical parameters:

[contact-form-7 id="b88c0ec" title="product form"]