First. Inclined Screw Conveyor Product Introduction:

Inclined Screw Conveyor, also known as Mobile Screw Conveyor or Stranded Screw Conveyor, is suitable for conveying bulk materials in chemical industry, metallurgical industry enterprises and paper making, construction engineering and other industries, such as: cement, coal powder, carbon ash and so on. Because the machine can be moved at will, and horizontal, inclined, vertical position can be continuous conveying, so it is especially suitable for field mobile operation, such as concrete mixing plant, bulk material storage and transportation and other occasions can especially reflect its advanced and superiority.

Second.Inclined Screw Conveyor features:

1、It is suitable for conveying materials at an incline within the range of 90° and occupies a small area.

2、Conveying capacity can reach 142 cubic meters/hour, and it can realize 4-70 meters long-distance conveying.

3、Fast rotating speed, uniform conveying, can ensure that the material is not blocked in the conveying process.

4, good sealing, the whole conveying process basically does not produce dust pollution, material overflow, etc., improve the operating environment.

5, through the loading and unloading gate to control the material flow.

Third, inclined screw conveyor tilt angle:

1、Tubular screw conveyor with shaft inclination angle: about 45°.

2、U-shaped screw conveyor with shaft inclination angle: about 20°-30°.

3、No shaft tubular screw conveyor inclination angle: about 30 °

4、No shaft U-type screw conveyor inclination angle: 20 ° – 30 ° or so

Note: For a poor fluidity of the material, the inclination angle can reach 50 °, but the use of such a way of conveying materials, the need to apply a certain amount of pressure on the inlet, plus the material is squeezed into the main body of the conveyor, and the bottom of the equipment bearings need to withstand enormous pressure, the bearings are easy to damage.

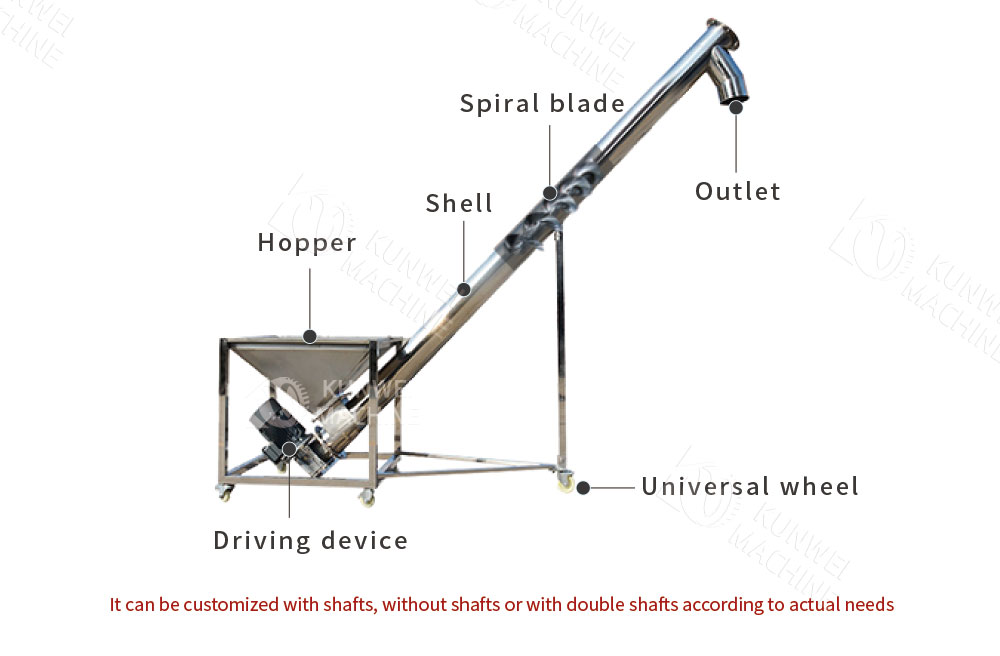

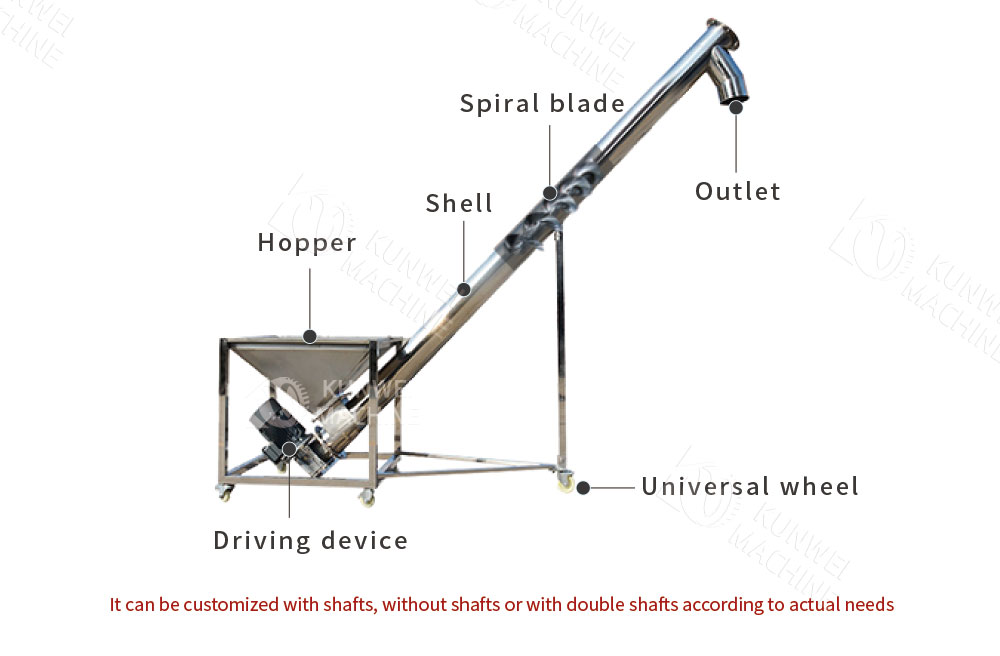

Fourth, inclined screw conveyor structure characteristics:

1, inclined screw conveyor is a non-foundation fixed, it is driven by the motor gearbox shell tube spiral body connected in turn, combined as a whole.

2, the end of the shaft and the spiral body involute spline (or rectangular spline) coupling, easy to install and disassemble, large bearing capacity, safety and reliability.

3、Conveyor shell is made of steel pipe through the flange to connect each section as a whole, so it has good overall rigidity, so that you can choose the working position and working attitude, and can be disassembled and moved at will.

4, the inlet and outlet can be made according to the work site conditions of the required angle of inclination, and fixed with the connection of other supporting equipment.

5, the machine’s spiral blade disk-shaped steel belt rolled from the whole connection blade, the spiral surface of the high degree, the outer diameter of the inner hole spiral distance size, conveying conditions, (if a single piece of group welding blade to achieve the above requirements).

Fifth, the working principle of inclined screw conveyor:

Inclined Screw Conveyor is through the rotating screw blades to push the material and screw conveyor transportation, so that the material does not rotate with the screw conveyor blades together with the force is the weight of the material itself and the friction resistance of the screw conveyor casing on the material.

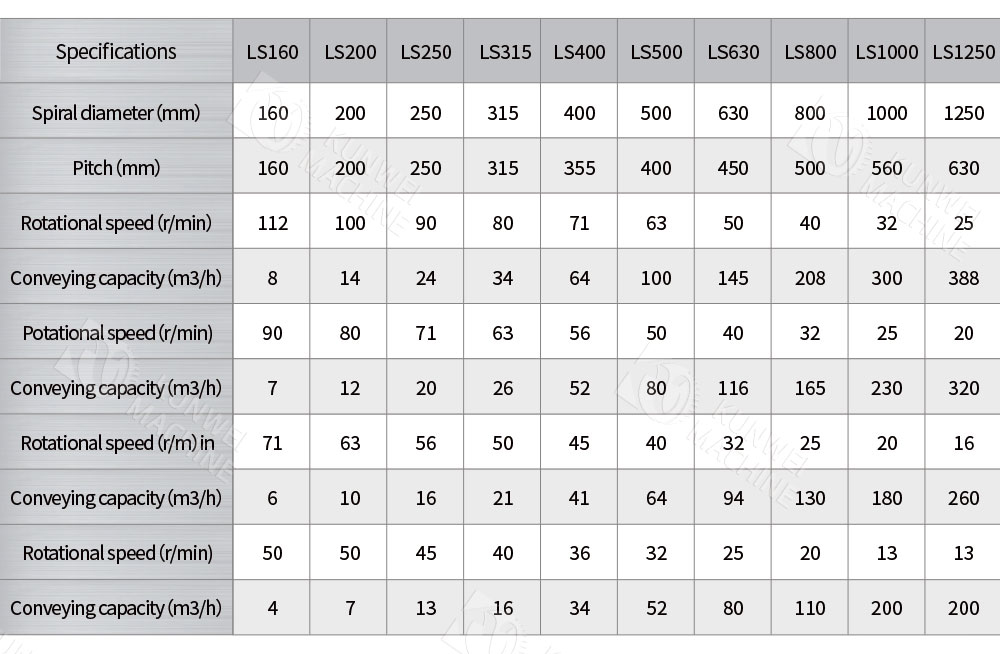

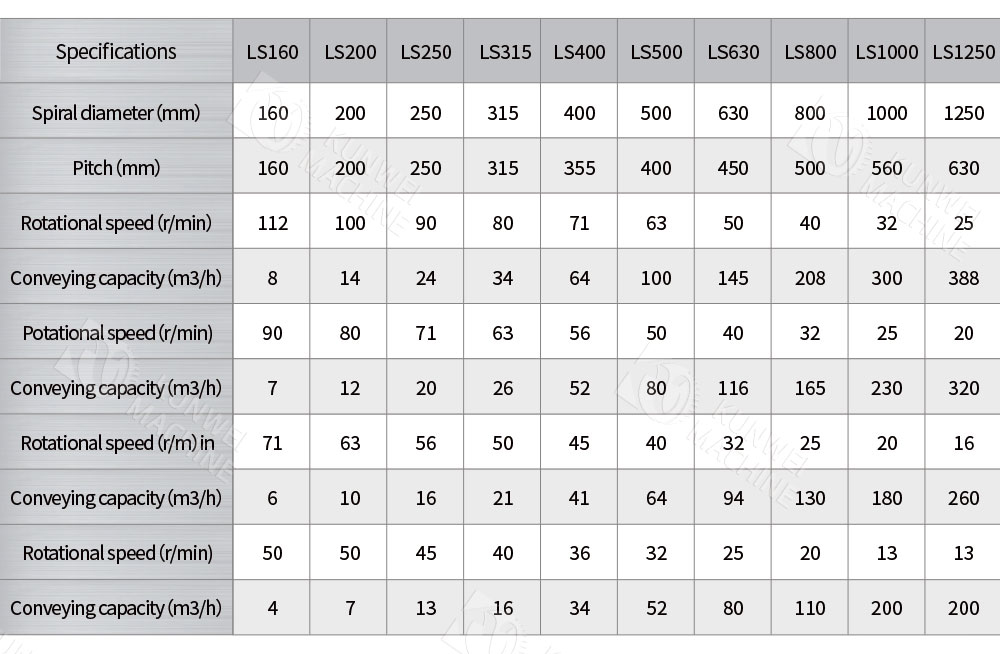

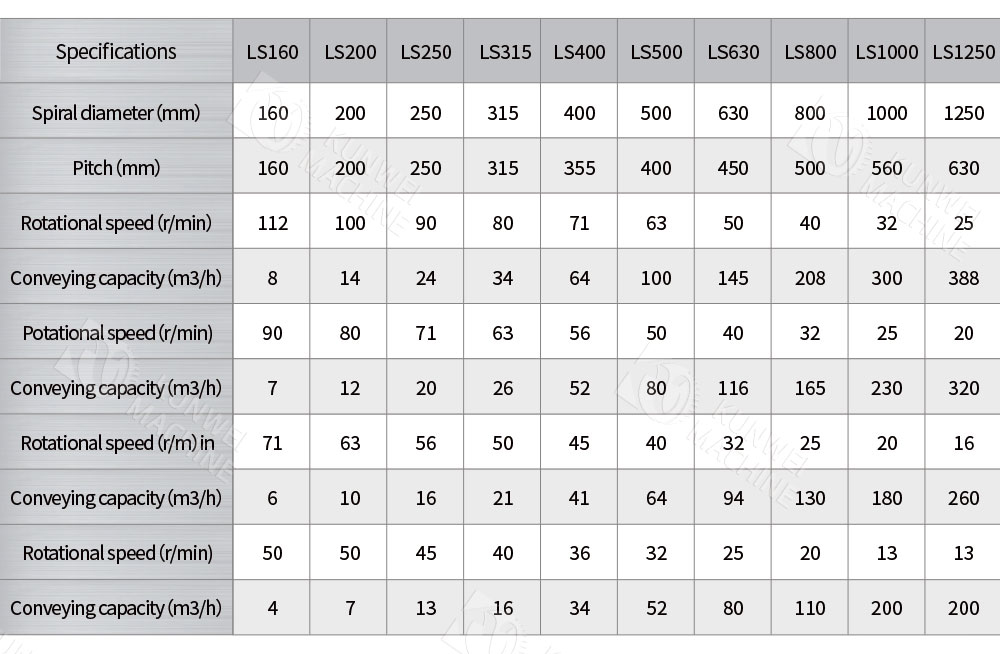

Inclined Screw Conveyor model parameters: