Product

Single Blade Shaftless Screw Conveyor

First, shaftless screw conveyor product introduction: For many materials that are difficult to convey, people have been looking for a reliable conveying method, and shaftless screw conveyor is a better solution . Shaftless Screw Conveyor adopts screw

First, shaftless screw conveyor product introduction:

For many materials that are difficult to convey, people have been looking for a reliable conveying method, and shaftless screw conveyor is a better solution . Shaftless Screw Conveyor adopts screw to change into shaftless screw, and there is a replaceable liner in the U-shaped groove, simple structure, the material is inputted from the inlet and pushed by the screw and outputted from the outlet, and the whole transmission process can be carried out in a sealed groove. Shaftless Screw Conveyor can convey materials that traditional shafted screw conveyor and belt conveyor can not or not easy to convey, such as granular and powdery materials, wet and pasty materials, semi-fluid and viscous materials, materials easy to be entangled and easy to be clogged, and materials with special sanitary requirements.

Second, shaftless screw conveyor working principle:

Shaftless Screw Conveyor is driven by the motor cycloid reducer operation, by mechanical sealing shaft and shaftless screw body on the connecting disk drive and make the screw rotating work, when the material into the U-shaped groove above the inlet, shaftless screw conveyor will be through the rotation of the spiral to let the material along the spiral forward, and finally the material from the U-shaped groove below the outlet fall.

Third, shaftless screw conveyor product features:

1, good environmental performance, the use of fully enclosed and easy to clean the screw surface can ensure that the materials sent without contamination will not leakage of conveyed materials.

2, large conveying capacity, conveying capacity is the same diameter shaft screw conveyor 1.5 times.

3、Large turning distance, low energy consumption, the discharge port is not blocked.

4, long conveying distance, single conveyor length up to 60 ~ 70m.

5、Compact structure, space-saving, beautiful appearance, easy to operate, economical and durable.

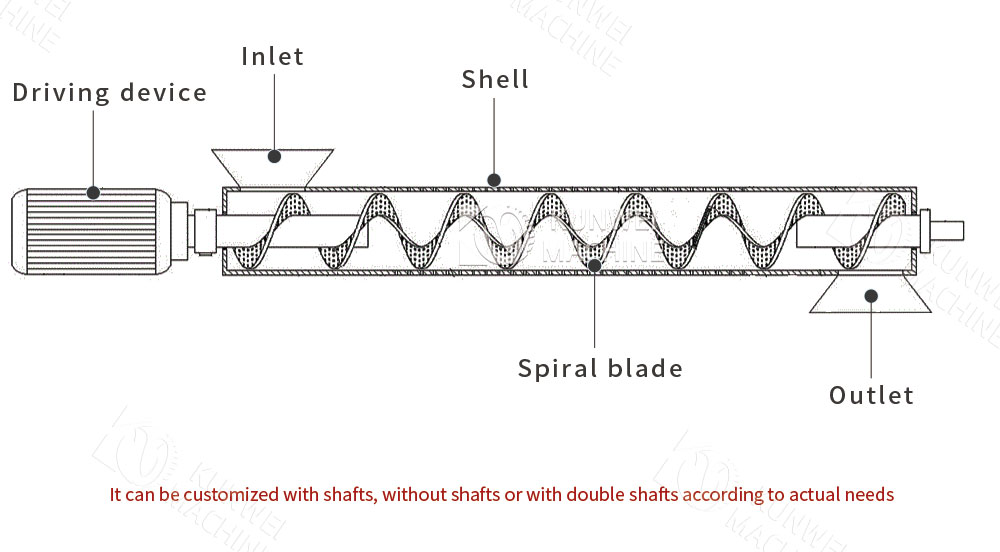

Fourth, shaftless screw conveyor structure composition:

Shaftless screw conveyor is mainly composed of driving device, head assembly, casing, shaftless screw body, trough liner, inlet, outlet, cover (when needed), base and so on.

1, drive device: cycloid reducer or shaft-mounted hardened gear reducer, the design should be as far as possible to drive the device located in the discharge port end, so that the spiral body in operation in the state of tension.

The head is assembled with thrust bearing, which can bear the axial force generated when conveying materials.

2、Case: the case is U-type or O-type, with rainproof cover on the top, made of stainless steel, carbon steel or fiberglass.

3、Shaftless spiral body: made of stainless steel or carbon steel.

4、Tank liner: made of wear-resistant plastic plate or rubber plate or cast stone plate.

5、Feeding and discharging port: there are two kinds of square and round, the general form of feeding and discharging port is decided by the user.

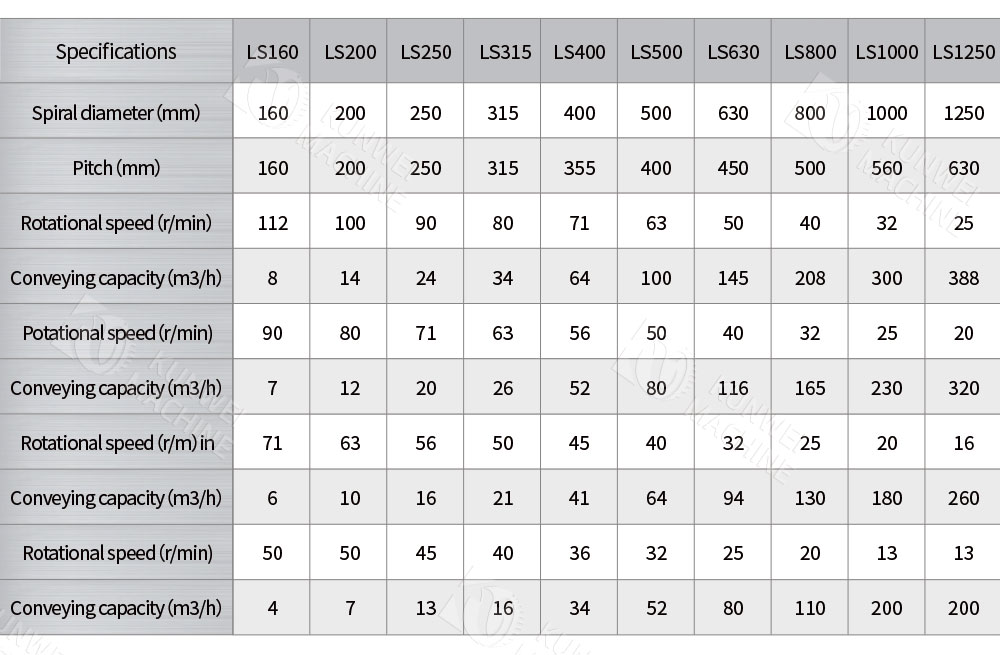

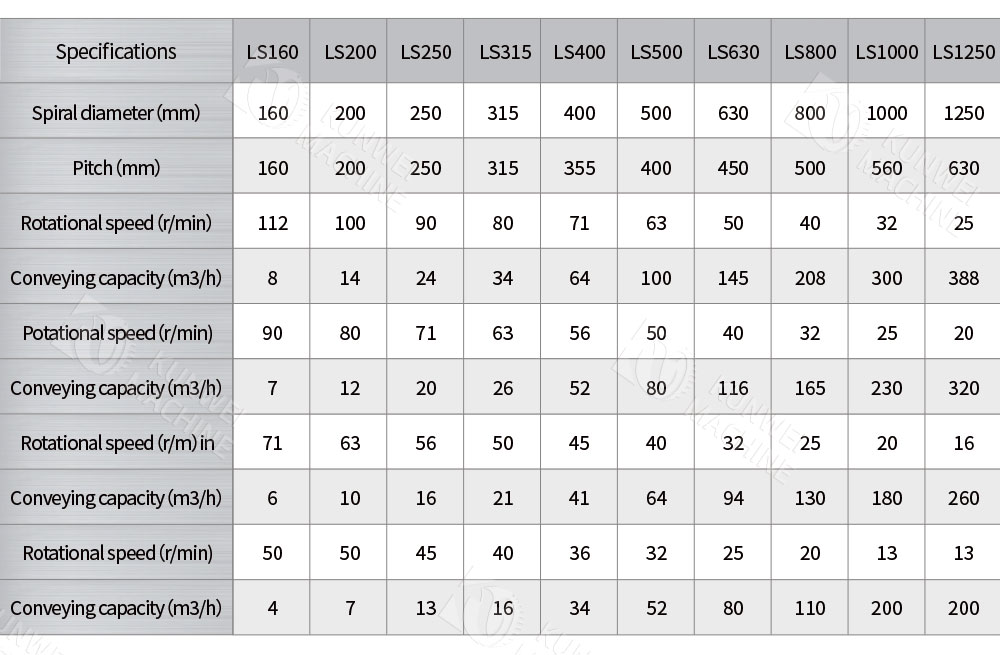

Five, shaftless screw conveyor specifications:

Shaftless screw conveyor is improved on the basis of LS type screw conveyor. Because LS type screw conveyor can not transport some sticky and winding materials, so there is a shaftless screw conveyor. Shaftless screw conveyor not only has a breakthrough in materials, but also exceeds 1.5 times of LS-type shafted screw in conveying capacity. And the single pipe conveying length reaches 60 meters of conveying distance.

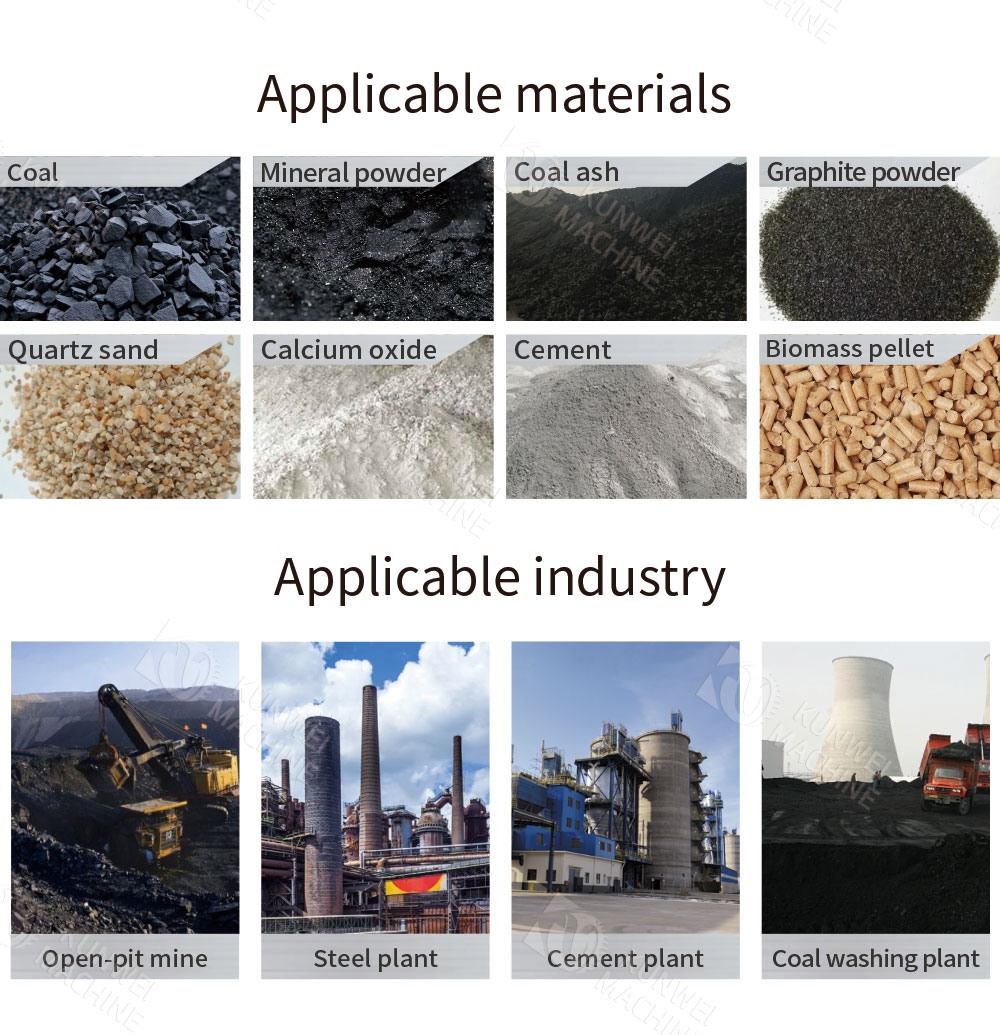

Sixth, the shaftless screw conveyor applicable range:

Shaftless screw conveyor is widely used in chemical industry, building materials, metallurgy, and other departments, in the case of inclination angle of 20 °, conveying viscosity is not big, not easy to deteriorate, too late to caking powder, granular and small pieces of material.

1、Sewage treatment plant

Shaftless screw conveyor can be used in sewage treatment plant to convey solid debris, such as sludge, mud and sludge dewatering machine mud cake and other materials. It is installed directly after the slag blocking and salvaging or sludge dewatering equipment, manufactured into a sealed structure, conveying and pressing, playing a role in pooling and slag reduction, etc., to facilitate subsequent processing. Because the screw has no shaft, the material is not easy to clog.

2、Rubbish treatment plant

Garbage has many impurities, high water content and easy to rot, so for conveying equipment, its sealing is very important, the shaftless screw conveyor adopts the fully enclosed conveying and easy to clean screw surface, which can ensure the environmental hygiene and the sent materials do not leak.

3、Industrial waste transportation

Such as boiler coal system, solid waste incineration and so on. Due to the design of no center shaft, the use of a certain degree of flexibility of the overall steel screw to push the material, can convey some winding materials, not easy to clog.