First. Vertical screw conveyor product introduction:

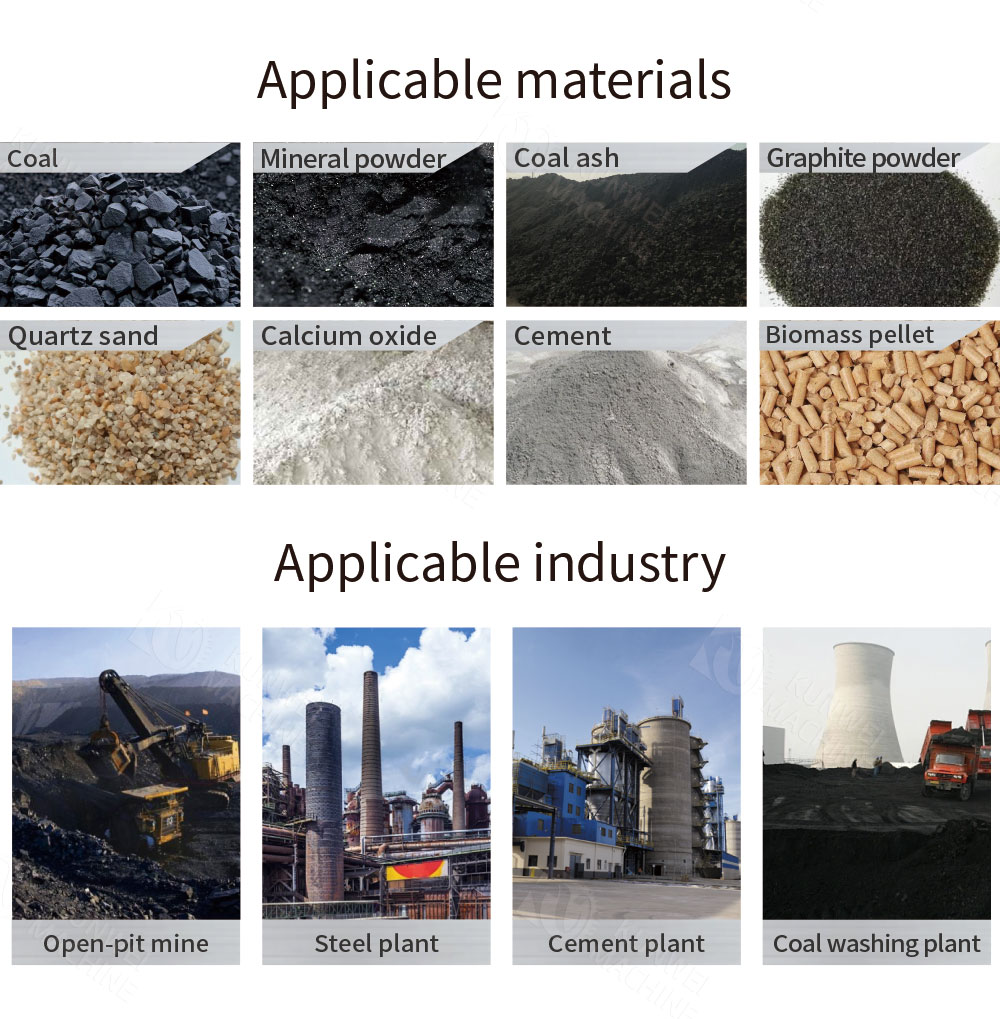

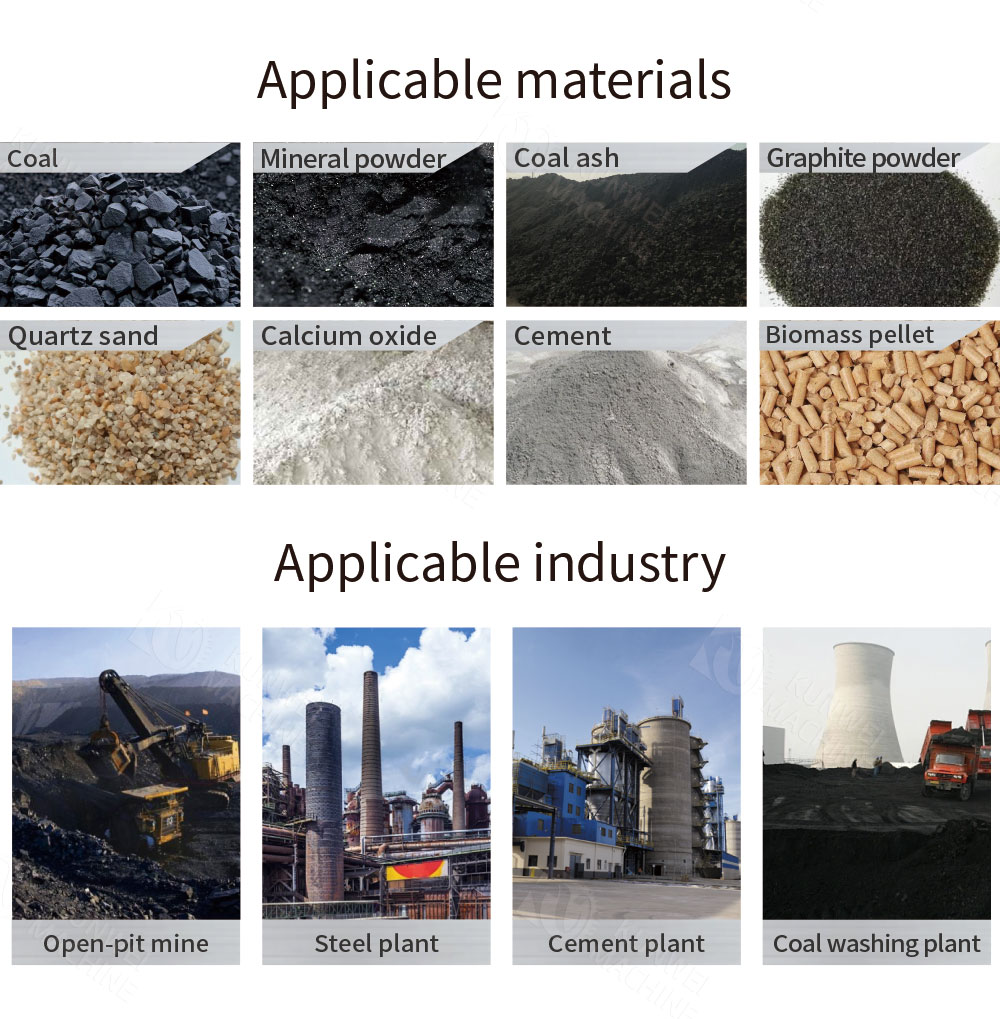

Vertical Screw Conveyor is a continuous conveying equipment that conveys materials for lifting by utilizing forced feeding screw rotation. Vertical Screw Conveyor is suitable for powdery, lumpy and granular materials, such as cement, ash, sand, stone, coal dust, lump coal and other materials. It is used in building materials, metallurgy, chemical industry, mining, machinery manufacturing, coal ash and other industries. Vertical Screw Conveyor has a small circulation area in the hub, so it is not suitable for conveying easily deteriorated, viscous and lumpy materials.

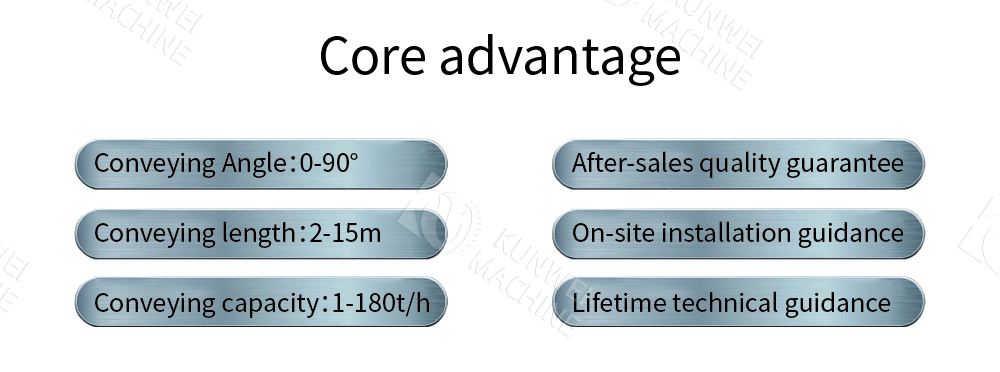

Second.vertical screw conveyor features advantages:

Third, vertical screw conveyor applicable scope:

Vertical screw conveyor is suitable for vertical or large inclined angle conveying powdery, granular, non-viscous dry materials with capacity of 1.3t/m3, such as oil bran, chemical raw materials, cement and so on. The temperature of materials generally can not exceed 80 degrees, vertical screw conveyor is not suitable for conveying lumpy and viscous materials.

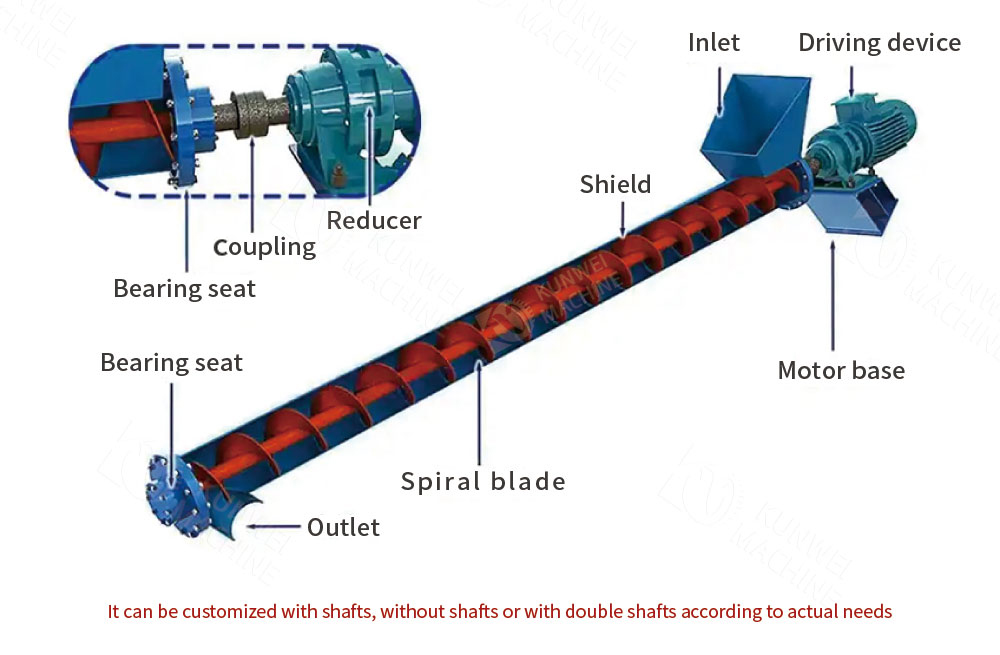

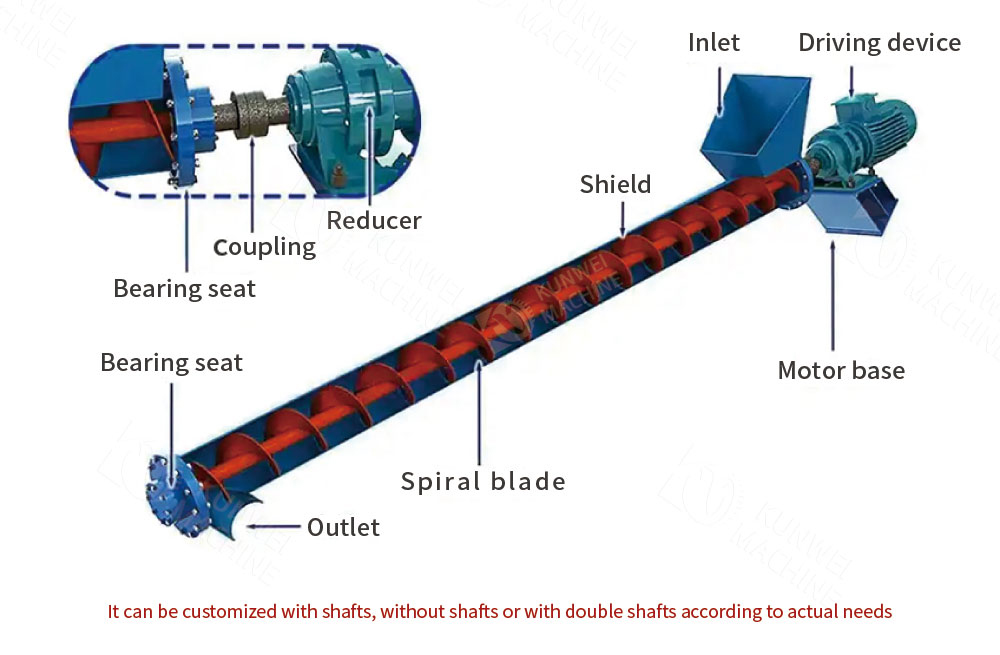

Fourth.Vertical screw conveyor structure composition:

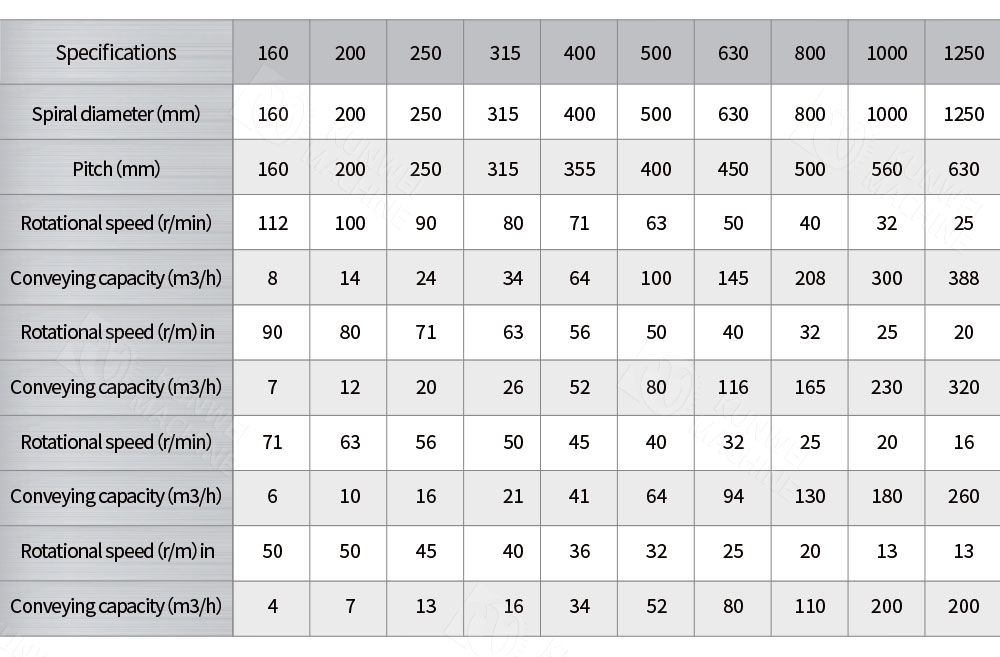

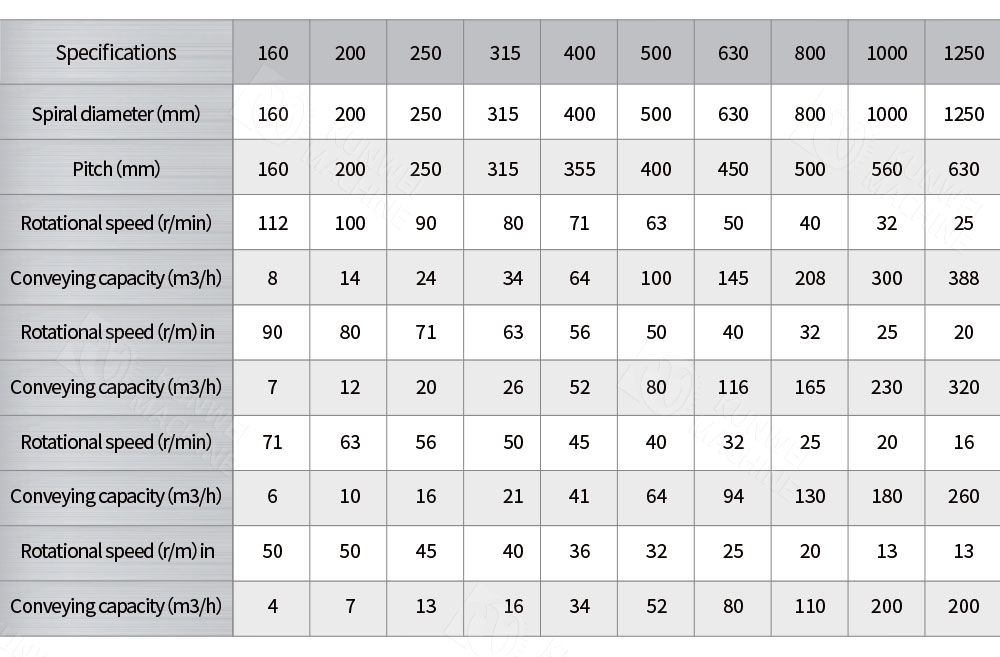

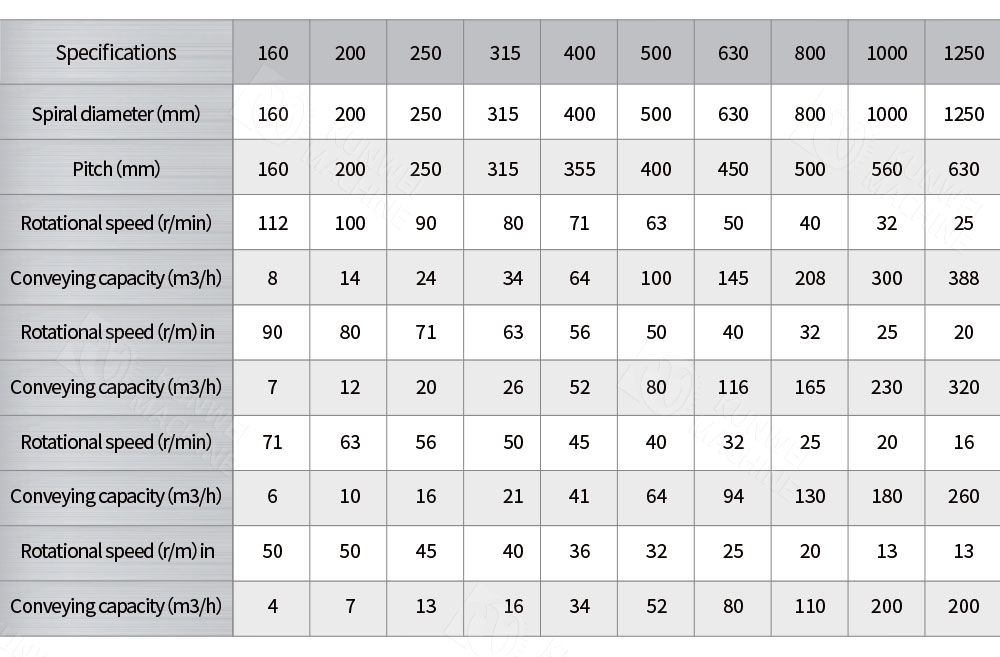

Fifth. Vertical screw conveyor technical parameters:

1, vertical screw conveyor can be calculated according to the following empirical formula Q = 8.0073n (m3 / n) where: Q = conveying capacity (m3 / n); D = screw diameter (m); n = screw speed (r / min ).

2, vertical screw conveyor motor power according to the following empirical formula for calculation N = 0.015258856QH (Kw) where: N = motor power (Kw); Q = conveying capacity (m3/n); r = material weight (t/m3); H = distance between the inlet and outlet (m).

3, length combination: vertical screw conveyor height (order height), is the distance between the feed port to the discharge port, from 2.5 meters to 15 meters, 0.5 meters a grade, the user can choose according to need.

4,Driving device: Vertical screw conveyor adopts up-driving type. The motor is installed in the head of the main machine, and the power is transmitted to the main shaft through the belt, which drives the screw to run.

Model 200 and 250 set up a single drive type, large configuration motor power 15Kw; 315 set up a single drive and double drive type. When the motor power is less than or equal to 15Kw, it adopts single-drive type; when the motor power is more than 15Kw, it adopts double-drive type. Forced feeding device with another drive device installed on the ground, should be unified design by the manufacturer.

[contact-form-7 id="b88c0ec" title="product form"]