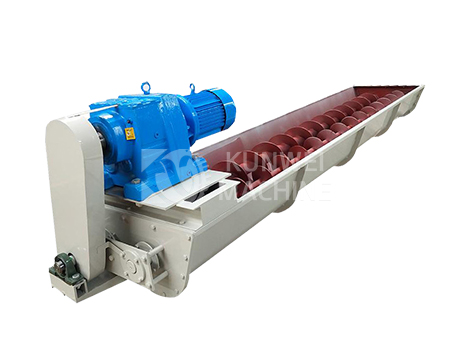

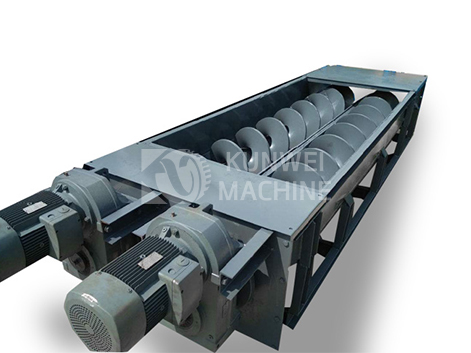

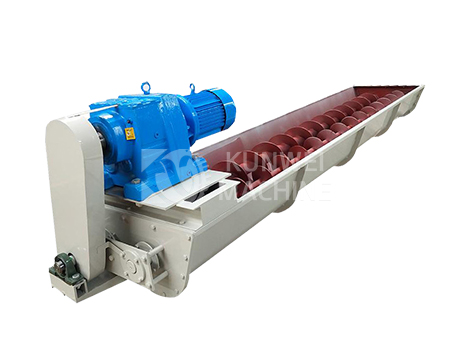

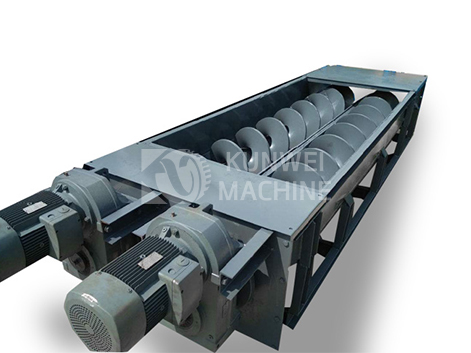

First. Product introduction of double-blade shaftless screw conveyor:

Double-blade shaftless screw conveyor is a screw conveyor with two rotating shafts welded with rotating blades. To put it bluntly, it is the two screw conveyor organic combination together, grouped into a double screw conveyor. Screw conveyor rotary shaft rotation, determines the direction of material transportation, but the general screw conveyor in accordance with the design of a single conveyor to design the rotary blade. When conveying in the reverse direction, it will greatly reduce the service life of the conveyor.

Double-blade shaftless screw conveyor adopts thicker belt spiral, blade structure for double spiral blade shaftless design, compared with single-blade shaftless screw conveyor, double-blade shaftless spiral blade lead angle (or screw angle) than single spiral blade is high, so its conveying capacity is larger, and it can prevent viscous, entangled materials in the process of conveying the phenomenon of clogging, generally used in sewage plants, waste treatment plants are used more.

Second, double blade shaftless screw conveyor structure features advantages:

1、U-shaped section: the shape is basically the same as LS series screw conveyor.

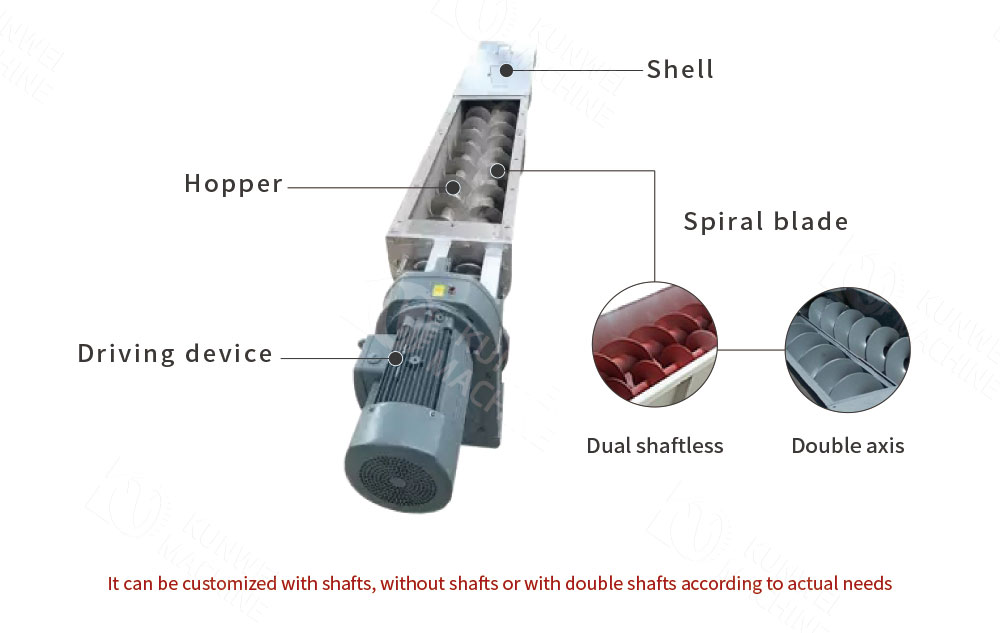

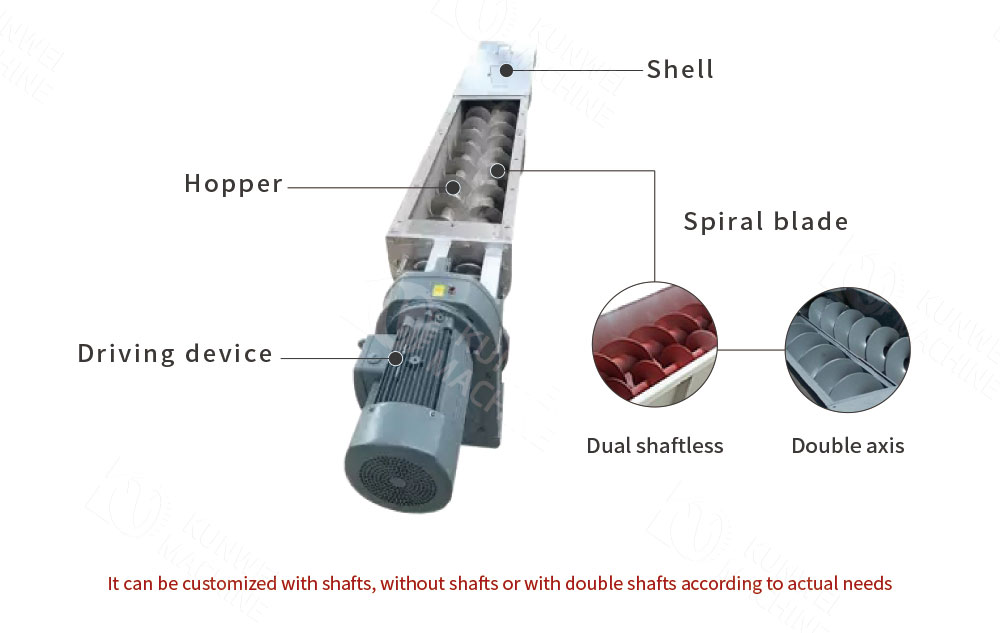

2、Double Shaftless Screw Conveyor screw body is a thicker ribbon spiral, shaftless screw, the head is connected with the drive shaft. The structure is divided into single and double blades, the material is divided into carbon steel, stainless steel, according to the pitch ratio of 1:1 and 2:3 two kinds.

3、Sliding liner: the middle and tail of the shaftless spiral body are working support parts, the material is divided into high-strength engineering plastics, stainless steel and other high wear-resistant materials.

4、Working parts: basically the same as WLS-type working parts, absorbing and adopting the mature technology of LSY series screw conveyor and the structural characteristics of WLS-type screw conveyor.

5, round tube shell: good airtight performance, up to airtight level (0.02mpa) performance, can work under positive and negative pressure conditions.

6、No center shaft design, anti-tangling, can prevent the material from clogging in the conveying process.

7、Double blade structure, the conveying output per unit time is bigger than single shaft.

8、With fully closed design structure, it can reduce the dust phenomenon, reduce the pollution to the environment, and also can prevent the material leakage.

9, easy to clean the spiral surface, reduce the external pollution of the conveyed materials.

10, the use of rubber or cast stone plate material wear-resistant liner, long service life.

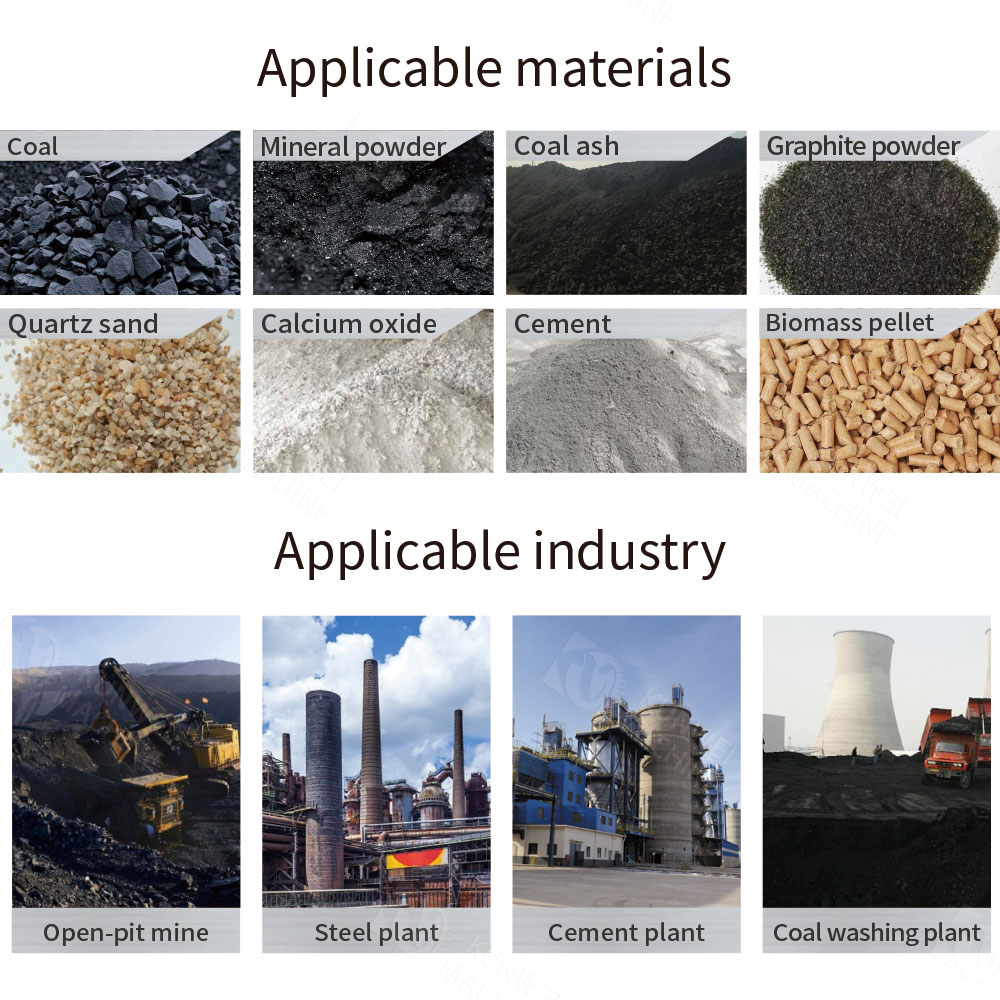

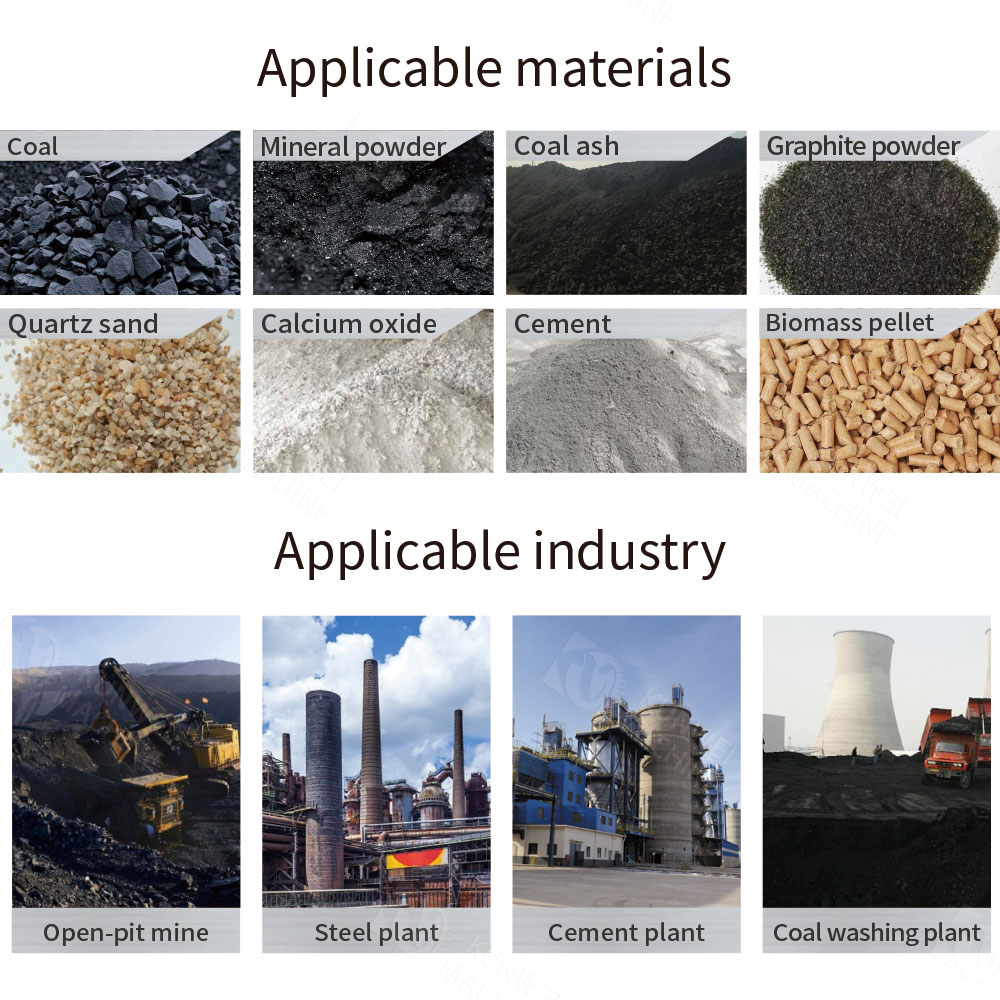

Third, the application scope of double-blade shaftless screw conveyor:

Double-blade shaftless screw conveyor is mainly used for conveying viscous and easily entangled materials, such as garbage, cement, white ash and other materials, widely used in building materials, chemical industry, electric power, metallurgy and other industries, can be arranged horizontally or inclined.

1、Ordinary model: It has unique advantages in conveying entangled materials (such as domestic garbage) and fiber materials (such as wood chips, wood chips).

2、Heat-resistant model: conveying hot materials and high-temperature materials without tail-end support. Such as high-temperature recovery of blast furnace dust, high-temperature furnace ash (slag) conveying.

Fourth, double-blade shaftless screw conveyor structure:

Fifth. Technical parameters of double-blade shaftless screw conveyor:

Sixth, double-blade shaftless screw conveyor customer cases:

Seventh, double-blade shaftless screw conveyor technology patents: