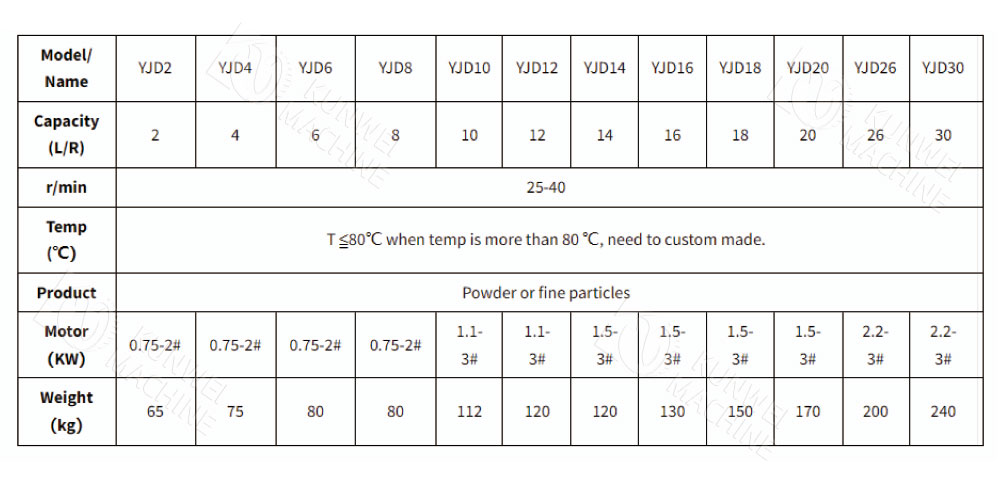

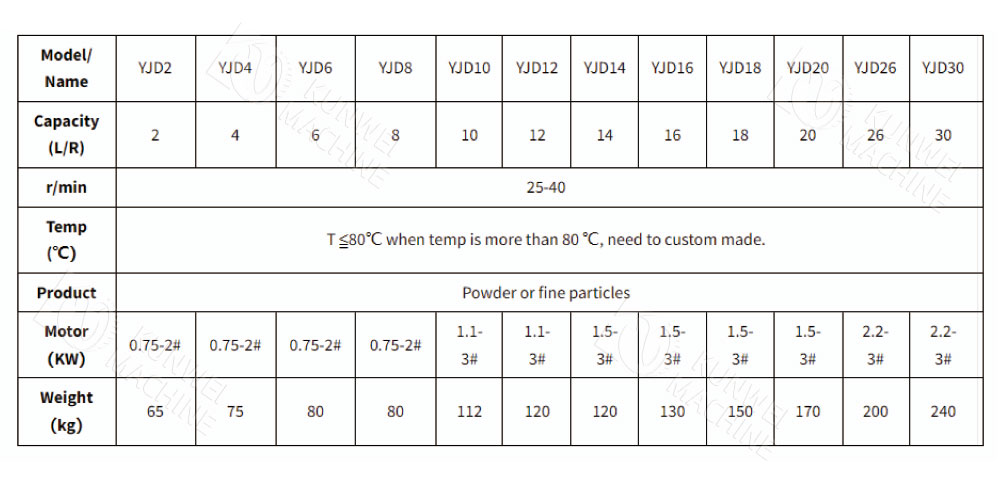

Product

Star Discharger

First. Star unloader product introduction: Star unloader as a special unloading equipment, is composed of rotor impeller with several blades, shell, seals and reducer, motor, etc., plays a great role in cleaning and cleaning work. Star unloader is us

First. Star unloader product introduction:

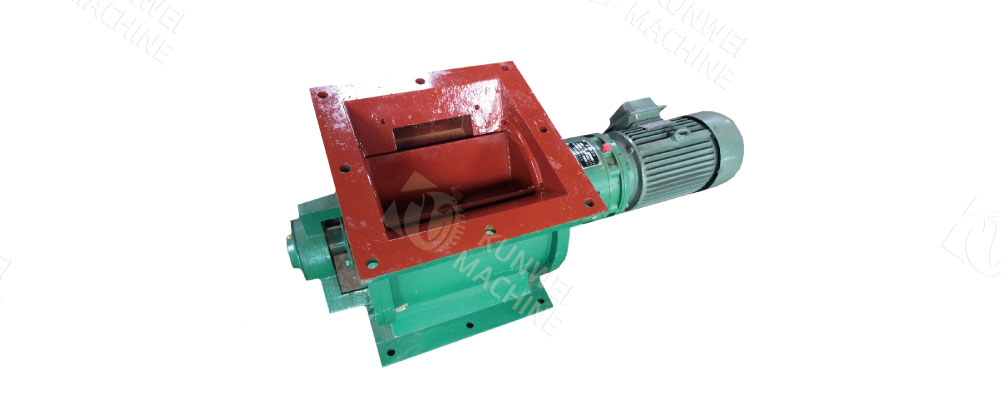

Star unloader as a special unloading equipment, is composed of rotor impeller with several blades, shell, seals and reducer, motor, etc., plays a great role in cleaning and cleaning work.

Star unloader is used to install in the discharge port of the unloader working under negative pressure, the upper part accepts the material discharged from the unloader, relying on the rotating impeller to play a role in conveying the material, but also assume the role of sealing to prevent the air from the discharge port in the process of pneumatic conveying inhalation.

Second, star discharger product features:

1、Compact structure, beautiful modeling, easy to use.

2、Smooth running, low noise.

3、Because the bearings, gear box left the shell a distance, for high temperature, lubrication have been greatly improved.

4、By adopting the principle of planetary rotation, the input and output shafts are on the same axis, and there is the uniqueness of direct connection with the motor, thus the structure is compact, the modeling is beautiful and novel, the volume is small, and the weight is light.

5、Superior sealing performance, uniform and stable feeding, smooth discharging, low noise, less failure, long service life, high wear resistance.

6, bearings, gear box, away from the valve body, to avoid the impact of high temperature dust, before and after the end cover sealing performance is good, to prevent dust leakage, to extend the service life of the motorized parts, lubrication system.

7、Strong overload capacity, impact resistance and small inertia force, suitable for frequent starting and inverse rotation.

8, according to the user needs to configure special special motor, such as explosion-proof, frequency control, speed control, marine motors, etc., to meet the user’s special requirements. In the material can also be based on user needs for special processing, such as high temperature, corrosion resistance, stainless steel, flexible blade, explosion-proof impeller and so on.

Third, star unloader product classification:

Star unloader is divided into ordinary type, pressure-resistant type, high temperature type three categories.

1、Ordinary type: can be used in 80 degrees below and room temperature on the usual materials, it can be continuous and uniform to the feeding pipe material, and in the system and separation of dust collection department, it can be used as a discharger function.

2、Pressure-resistant type: It adopts closed rotor, which can be widely used in suction conveying, pressure conveying airflow conveying system and negative pressure conveying equipment, which can ensure that the pressure of the airflow in the conveying pipe does not leak, and can safely convey and collect materials, so it is known as the air locking machine in this regard, which is not only pressure-resistant, but also has both the common type function.

3、High temperature type: according to the temperature rise of material conveying and discharging port is different because the temperature quality has an effect on the expansion of the body, as well as unfavorable to the bearings and oil sealing system.

Fourth, star unloader working principle:

1, star unloader commonly used in pneumatic output system, for pressure output system or negative pressure output system, star unloader can be uniform, continuous supply of material to the feeding tube. To ensure that the gas and solids in the pneumatic output pipe are relatively stable, so that the pneumatic conveying can work normally, at the same time, it can also isolate the upper and lower air pressure of the unloader and play a role in locking the air. Therefore, the star unloader is an important part commonly used in pneumatic conveying system.

2,When the materials in the upper silo fall down to fill in the gap between the blades by their own weight, and are discharged in the lower part with the rotation of the blades. Therefore, the star unloader can be quantitative and continuous discharge.

3,Temperature-resistant type it conveys the material temperature up to 280°C both ends of the bearings and the impeller has a certain isolation, can prevent the ultra-fine powder material and bearing contact. High temperature type unloader conveying material temperature up to 500°C, using sprocket connection. There is a certain distance between reducer and unloader shell.

Fifth. the star type unloader applicable scope:

Star unloader can be used in the collection of material system, as a silo unloader, star unloader is currently the more advanced unloading device, commonly used in the dust removal system as one of the important equipment in the dust removal system, it is particularly suitable for dust, small particles of material, by the environmental protection, metallurgy, chemical industry, food, cement, road construction, drying equipment and other industrial industries, engineering projects.

Sixth. star unloader use precautions:

1, star unloader before use, check the number of lubricating oil in the reducer and the type of oil, replace the new oil after one month of operation, and change the oil once a year after that.

2, Connect the gas source interface, and check whether the interface is blocked by foreign objects, to ensure that the interface is clean and unobstructed.

3, Before using the star unloader, be sure that the rotor rotation direction is clockwise (from the speed reducer to extend the end of the shaft, and the arrow on the sprocket cover);.

4, star unloader before use, open the sprocket cover to check the tension of the chain, in the operation process should be regularly checked; at the same time to the chain and sprocket with the appropriate grease.

5, in the unloader throughout the use of the process, adjust the pressure reducing valve so that the pressure at the seal is greater than the valve body.