First. Reversing roller product introduction:

Conveyor redirecting pulley, also called guide pulley, is a common key component of belt conveyor, which is mainly used to change the running direction of the conveyor belt or press the conveyor belt to make it increase the wrapping angle with the transmission pulley. There is no difference between it and transmission pulley in structure, both are composed of spindle pulley bearing and bearing chamber. Reversing pulley is one kind of belt conveyor pulley, belt conveyor pulley includes reversing pulley, active pulley and surface increasing pulley. Reversing pulleys are mainly used to change the running direction of the conveyor belt, and the number of pulleys used is usually more than that of the active pulleys. Reversing roller is divided into light, heavy, td75 type and DT type.

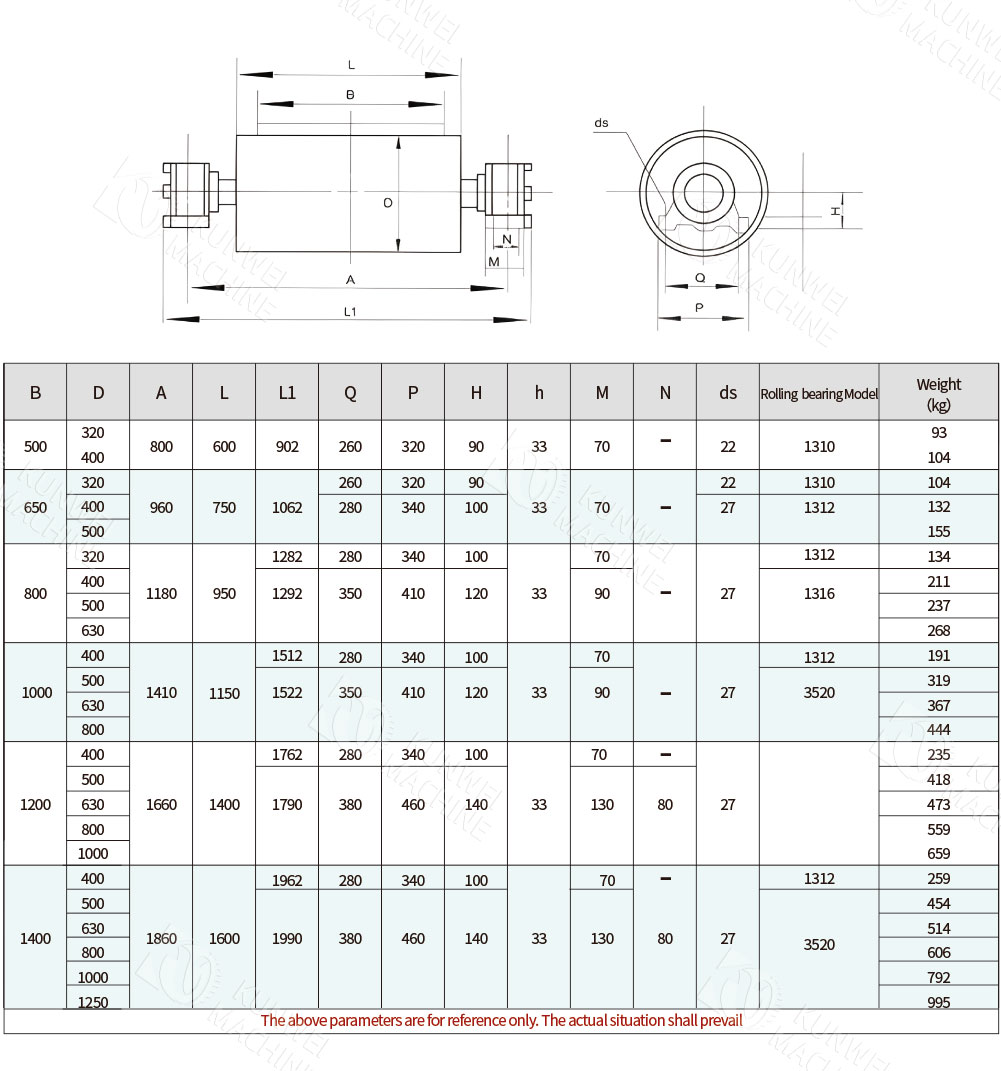

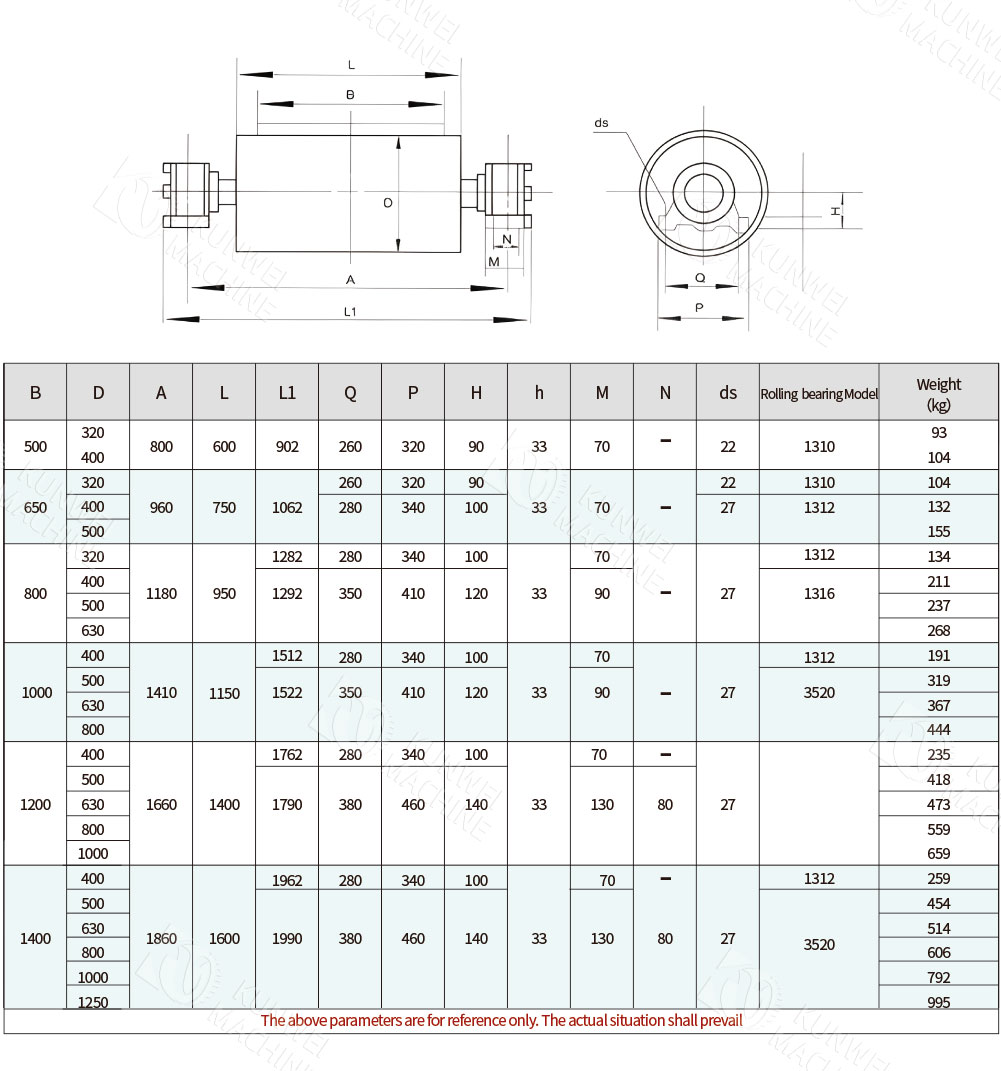

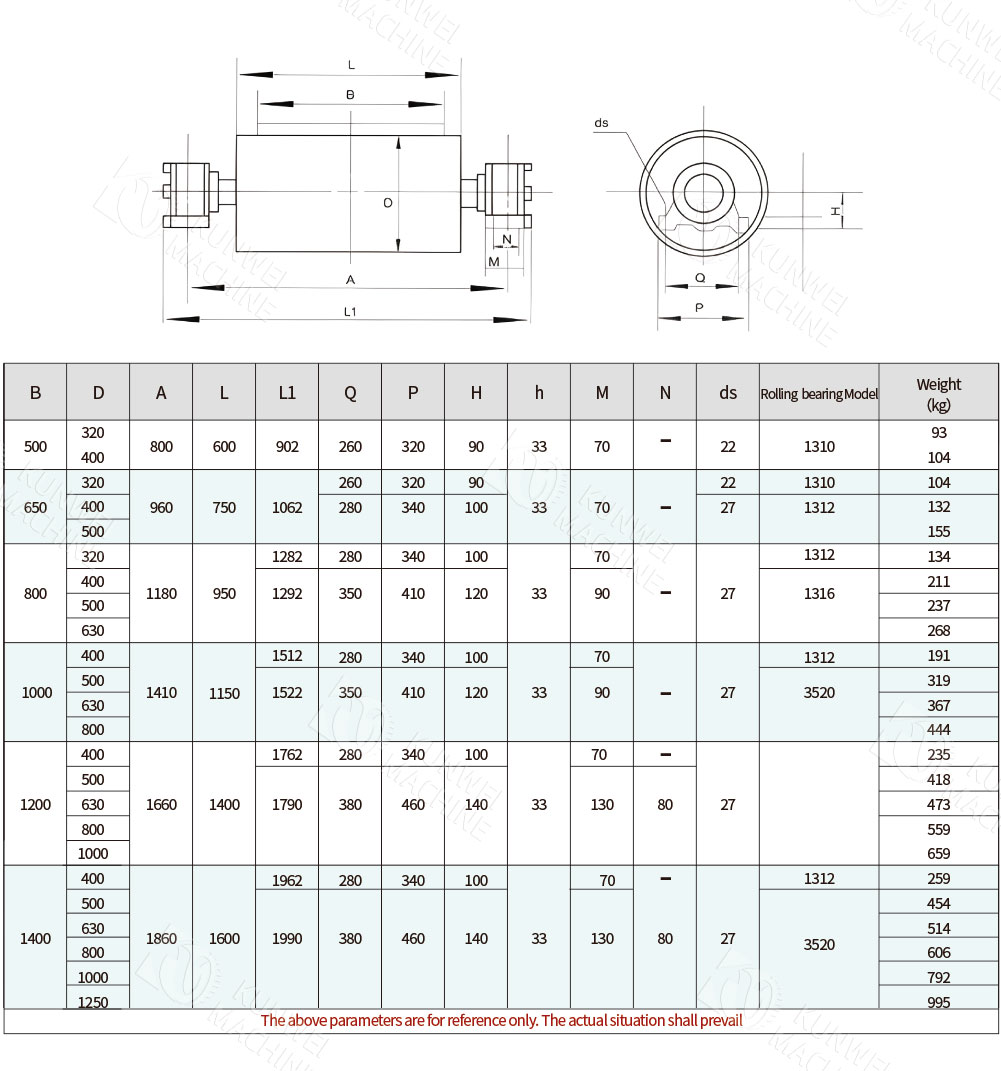

Reversing roller produced by Henan Kunwei Machinery has a stable structure, regardless of the size of the national standard design and production. The bearing frame of reversing roller adopts Havalor bearing frame, which is of standard design and reliable quality. The conveyor reversing roller has the characteristics of compact structure, light weight, less occupation, reliable performance, beautiful appearance, safe and convenient use, and can still work normally under the harsh conditions of dusty, wet and muddy.

Second, the composition and structure of the redirecting pulley:

Reversing pulley is mainly in the belt movement below, such as the belt delivery direction for the left, then the reversing pulley in the belt machine on the right, the main structure of the bearings and steel cylinders, the drive pulley is the belt machine’s active wheel, from the relationship between the two is just like a bicycle with two wheels, the rear wheel is the drive pulley, the front wheel is the reversing pulley; Reversing pulley and the drive pulley in the structure of the pulley is no difference, are composed of the spindle pulley bearing and bearing room transmission pulley Bearing and bearing chamber composed of transmission drum is divided into two kinds of master drive and slave.

Third, the main role of the reversing roller:

The main role of the conveyor roller contains two points, one is to be able to change the direction of operation of the conveyor belt; the second is to be able to press the conveyor belt so that it becomes larger with the driving roller wrapping angle. We can be subdivided into the following points:

1, the mandrel only bear bending moment, such as the shaft of the reversing roller group, the rotary shaft at the same time bear bending moment and torque.

2, the material of the spindle is generally through the rolling or forging of carbon steel or alloy steel, the general material is medium carbon steel, forty-five steel is common, for the force is relatively large and the size of the shaft is limited, and some of its special requirements of the shaft can be alloy steel, the choice of material for the four zero chromium.

3, reversing roller shaft generally need through heat treatment or surface strengthening treatment, in order to improve its mechanical properties and wear resistance, etc., in the general temperature, alloy steel and carbon steel modulus of elasticity is relatively small, so the choice of alloy steel can not improve the stiffness of the shaft; shaft material will generally be by the tempering process, when the shaft strength indicators do not meet the needs can also be selected by the merger of the tempering process, the permissible stresses should be permitted according to the symmetrical cycle of bending Correction.

Fifth, the scope of application of the reversing roller:

Reversing roller is suitable for conveying machinery, mainly used in metallurgy, mining, port terminals, cement and building materials, steel, coal and other fields, is a variety of belt conveyor drive device.

[contact-form-7 id="b88c0ec" title="product form"]