Product

Corrugated Edge Conveyor Belt

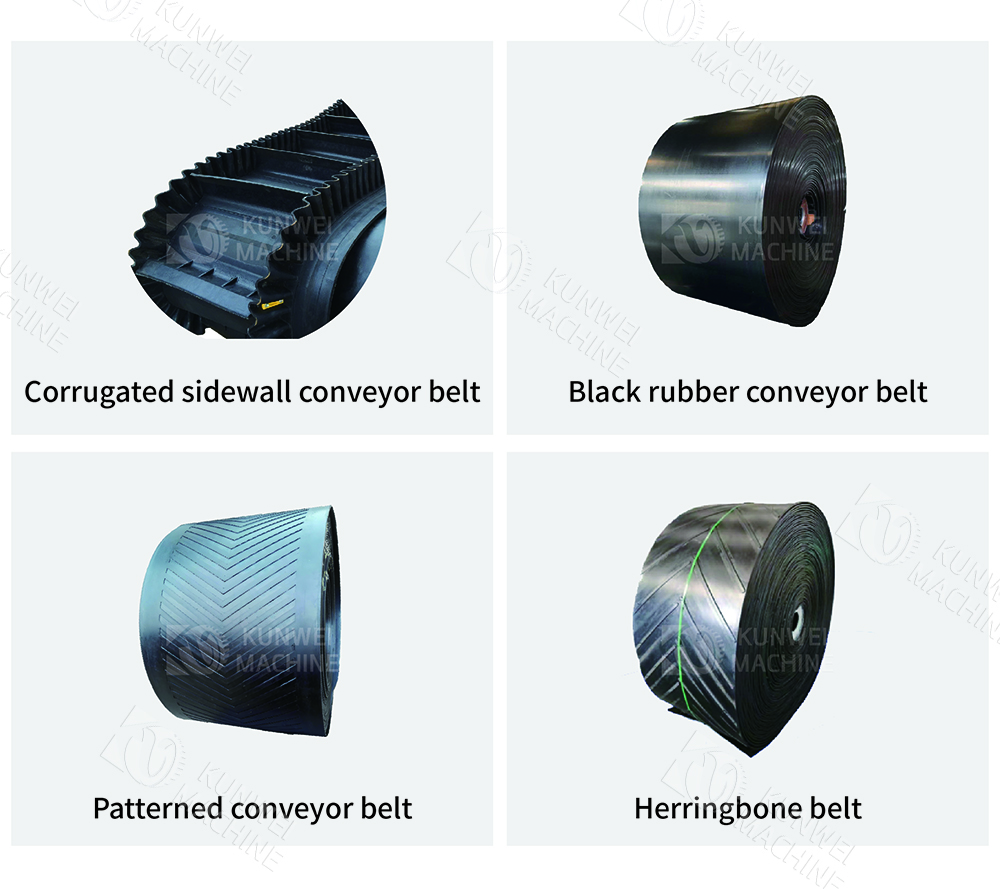

First. Product introduction of corrugated edged conveyor belt: Corrugated baffle conveyor belt with its advantages of large conveying inclination angle and large transportation capacity, etc., has been increasingly emphasized and adopted by many indu

First. Product introduction of corrugated edged conveyor belt:

Corrugated baffle conveyor belt with its advantages of large conveying inclination angle and large transportation capacity, etc., has been increasingly emphasized and adopted by many industrial sectors. Corrugated baffle conveyor belt is generally used in conjunction with corrugated baffle conveyor, whose practical angle is generally greater than or equal to 30 degrees, and can also be matched with general-purpose belt conveyor for horizontal, short-distance transportation (at this time, generally do not set up a partition). Waveform edge conveyor belt adopts the base belt with groove not larger than 0.03, and the edge and cross partition (horizontal conveying can not be) by two times vulcanization molding. The baffle plays the role of preventing the material from slipping and falling. In order to facilitate around the drum, the edge of the stall is designed as corrugated; the role of the cross partition is to support the material, in order to realize the large angle of conveyance, the use of T-type TC type. The gear edge and cross partition are connected with the base belt by the method of secondary vulcanization, which has high connection strength. It is used for conveying powdery, granular, small block, paste and liquid materials which are easy to be scattered.

Second. the structure of corrugated edge-blocking conveyor belt:

Corrugated flange conveyor belt consists of base belt, flange, cross partition 3 parts. The following are described in detail:

1, base belt: corrugated edge conveyor belt requires a certain degree of tensile strength and wear resistance. For the corrugated edge conveyor belt with empty edges, in order to adapt to the requirements of the angle of reorientation, the longitudinal requirements of the tape is flexible, and the transverse direction requires a certain degree of rigidity. The corrugated edge conveyor belt produced by Henan Kunwei Machinery adopts the transverse rigid base belt with special structure, which solves the phenomenon of large-size conveyor belt collapsing in the return process. The base belt is composed of four parts: upper cover rubber, lower cover rubber, belt core and transverse rigid layer. The thickness of the upper cover rubber is generally 3-6mm; the thickness of the lower cover rubber is generally 1.5-4.5mmz. The core material is subject to tensile force, which can be cotton canvas, nylon canvas, polyester canvas or steel wire rope. In order to increase the transverse rigidity of the base belt, a special reinforcing layer is added to the core, which is called transverse rigidity layer.

2, retaining edge: the company according to the use of corrugated retaining belt principle of corrugated retaining edge manufacturing process reform and innovation, in order to enhance the corrugated retaining edge of the tear resistance, resistance to bending and flexing, to avoid stretching and compression of the retaining edge is torn, increase the service life of the retaining edge. s-type corrugated retaining edge according to the bearing capacity can be divided into light (N), medium (S) and heavy (ES).

3, the cross partition: the company produces the cross partition made of fiber composite material, stiffness, enhanced impact resistance, to avoid deformation of the partition due to force. In the case of heavy wear and tear, for the convenience of maintenance, the cross partition can be made into chain embedded type, such as TS and TCS. when the inclination angle of the conveyor is less than 40 degrees, the cross partition adopts T-type or TS-type; when the inclination angle is more than 40 degrees, the cross partition adopts C-type, TC-type or TCS-type. When arranging the spacing of the partition, it should be considered to correspond to the wave crest of the wave-shaped baffle. In order to prevent the material from leaking down from the gap between the two and the dead space caused by the accumulation of material when unloading.

The bonding of the corrugated baffle conveyor belt, baffle, cross bulkhead and jade base belt produced by our company adopts the second low-temperature hot vulcanization bonding, which has high bonding strength, firm bonding, flatness, and does not fall off the board or shedding. The cross partition and corrugated baffle are connected with bolts, which increases the overall rigidity and improves the performance, and solves the problem of material leakage.

Third, the corrugated baffle conveyor belt product features:

1, increase the conveying angle (30 ~ 90 degrees);.

2, covers an area of small, less investment.

3, large conveying capacity, higher lifting height.

4, from horizontal to inclined (or vertical) can be a smooth transition.

5,Suitable for conveying powder, granule, small lump, paste and liquid materials which are easy to be scattered.

6, low energy consumption, simple structure, high tape strength, long service life.

Fourth, corrugated edge conveyor belt jointing method:

All conveyor belts must be connected into a ring to be used, so the good or bad of conveyor belt joints directly affects the service life of conveyor belts and whether the conveyor line can run smoothly and smoothly. General conveyor belt joints commonly used methods are mechanical joints, cold bonding joints, hot vulcanization joints and so on.

1,Mechanical joint method

Generally refers to the use of belt buckle joints, this jointing method is convenient and economical, but the efficiency of the joint is low, easy to damage, and has a certain impact on the service life of the conveyor belt products.

2,Cold bonding joint method

Cold bonding adhesive is used for jointing. This jointing method is more efficient and economical than mechanical jointing, and it should be able to have a better jointing effect, but from the practical point of view, it is not very stable due to the difficult to master the process conditions, and the quality of the adhesive has a great influence on the jointing.

3, hot vulcanization joint method

Practice has proved to be the most ideal method of jointing, can ensure high joint efficiency, but also very stable, joint life is also very long, easy to palm!