Product

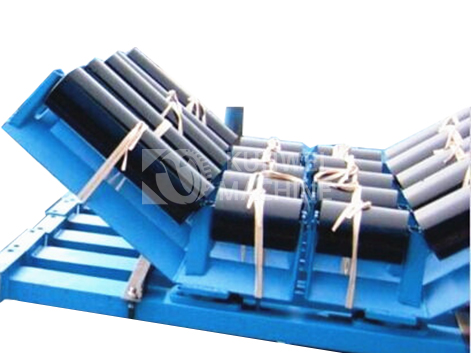

Grooved Roller Set

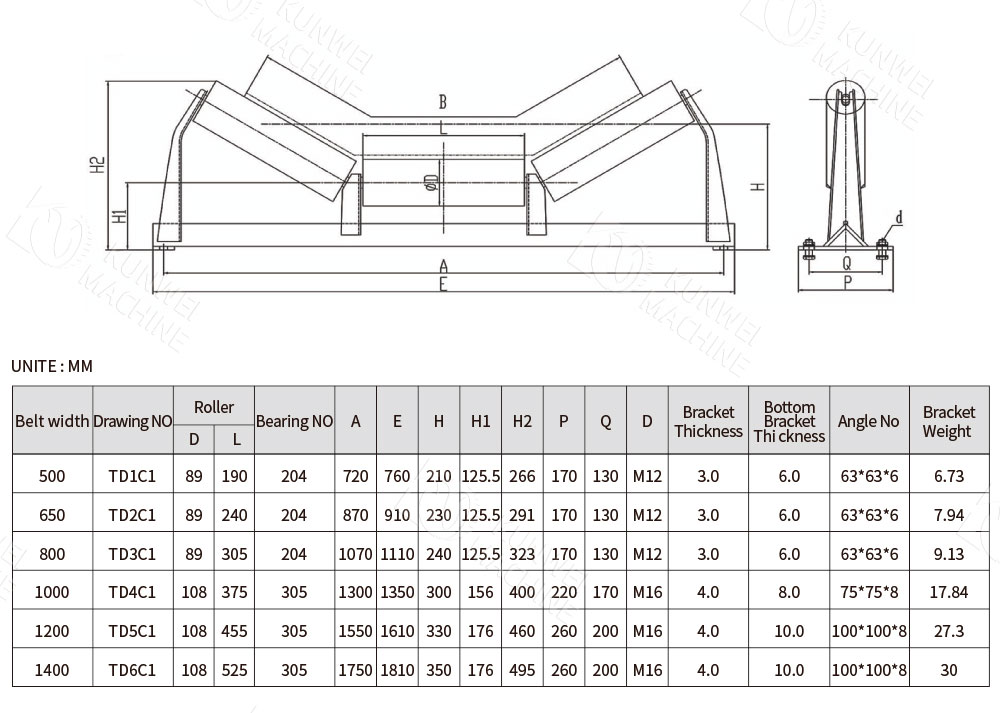

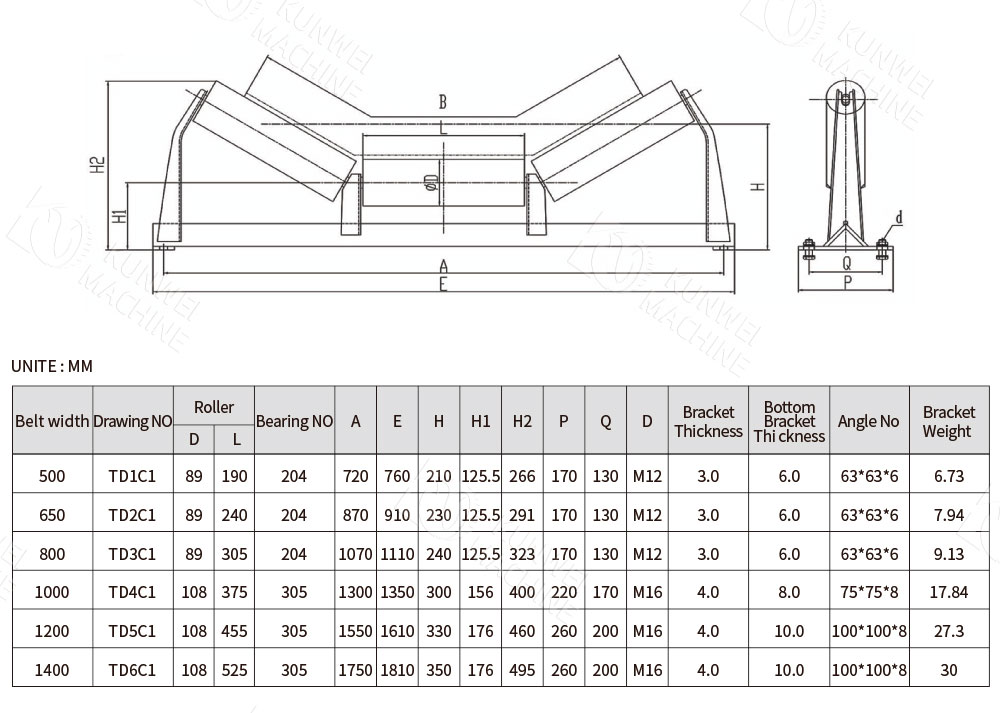

First. Introduction of grooved rollers products: Henan Kunwei machinery focus on grooved roller group production for many years, the production of roller series products are rich in variety, there are ordinary type roller, forward tilting type roller

First. Introduction of grooved rollers products:

Henan Kunwei machinery focus on grooved roller group production for many years, the production of roller series products are rich in variety, there are ordinary type roller, forward tilting type roller, quick-change bearing type roller, hanging type roller, three-chain rollers, reversible rollers, variable groove angle type rollers, transition type rollers, V-type rollers, and other related products, each roller product they have their own advantages and characteristics, Kunwei machinery production of grooved roller group is used for transportation of The groove roller set produced by Kunwe Machinery is used for the transportation of bulk materials, and the groove angle is 30℃.

The steel pipe used by Kunwe Machinery is made of special straight seam welded pipe for rollers, and the roundness is controlled within the special tolerance range. Shafts are made of cold drawn steel machined to standard tolerances. The bearing housings are made of cold-drawn steel plates stamped by several processes. Roller shells and bearing housings are welded together by automatic welding robots to form an integral structure with very high strength. Roller bearings are made of large clearance deep groove ball double sealed bearings of famous brands, which make the rollers have ideal static and dynamic balance. Roller seals are designed with high quality materials to effectively prevent impurities, water and air from eroding the inside of the rollers.

Second.grooved rollers product classification:

1、Parallel rollers have general type rollers, comb type rollers, forward tilting type rollers, steel rubber rollers type, spiral type rollers and so on.

2, centering rollers have general-purpose, friction reversible type rollers, strong type rollers, cone rollers, spiral type rollers, combined type rollers and so on.

3, cushioning rollers have spring plate type rollers, cushion ring type rollers, strong cushioning type rollers, adjustable elasticity type rollers, hanging type rollers and so on.

Third.grooved rollers product features:

1, grooved rollers with corrosion resistance: acid, alkali and salt are not corrosive.

2, groove roller hardness: wear resistance.

3, good sealing: grooved rollers fully sealed, equipped with plastic labyrinth seals at both ends, oil and grease will not leak, so that the rolling shaft for a long time; grooved rollers in a fully sealed state of operation.

4, groove roller ceramic surface: the formation of oxide film, smooth surface, non-adhesive materials, contact with the conveyor belt friction coefficient is small, reducing the winch driving force.

5, long service life of grooved rollers: grooved rollers are 2-5 times longer than steel rollers, and can reduce belt wear, the belt does not run edge, prolonging the service life of the belt.

6, low operating costs: grooved rollers can reduce the overall cost of the belt conveyor, reduce maintenance hours.

Fourth. grooved rollers product advantages:

All kinds of rollers have reasonable structure and reliable performance, the material used for roller skin is strictly selected, and high quality special welded pipe is used with strict tolerance requirements. Shaft material adopts cold-drawn round steel, bearing seat adopts high-quality steel plate stamping, sealing structure adopts PDC type, three sealing devices, dustproof and waterproof performance are better than the relevant national standards.

The grooved rollers produced by Henan Kunwei Machinery have the advantages of high aesthetics, low rotational resistance, long service life, low maintenance workload and high bearing capacity.

Fifth. Application scope of grooved rollers:

The grooved roller set is widely used in open dusty and corrosive environments, such as mines, power plants, steel plants, stone plants, cement plants, coal washing plants, salt plants, alkali plants, fertilizer plants, docks and other places.