What is the typical thickness of a conveyor belt

News 2025-05-06

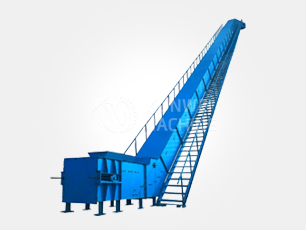

What is the typical conveyor belt thickness? This depends on the type of belt conveyor. Like our conventional coal conveyor belt conveyor, that is, mining belt conveyor, the thickness is generally in 10mm, in practice, 10mm thickness of the belt can meet most of the coal mines, power plants and other places of material transportation needs. Of course, it can also be increased or reduced according to the actual situation.

The thickness of 10mm belt represents the total thickness of the belt covering layer, covering rubber layer: the rubber layer covering the upper and lower surfaces, used to protect the internal structure, the thickness accounts for about 30%-50%; the core layer: usually consists of cotton canvas, nylon or polyester canvas, steel wire rope core (ST), or high-strength polyester canvas (EP) and so on, to provide tensile strength. The thickness of the core of the belt with multiple layers of canvas superimposed is about 50%-70% of the overall thickness (specific to the actual). This design ensures the impact resistance of the conveyor belt as well as prolonging its service life.

For special conditions, such as conveying sharp ores or high-temperature materials, the belt thickness may need to be increased to 12-15mm. the thickened wear-resistant layer effectively resists the cutting and abrasion of materials on the belt, while the high-temperature-resistant formula is able to withstand material temperatures of over 150℃. In port bulk cargo handling systems, due to long conveying distances and high loads, extra-thick belts of 16-20mm are sometimes used, and steel wire rope cores are added to these belts to increase tensile strength.

Overall, the thickness of the belt is determined by the cover rubber layer, the core layer and additional structures (such as transverse rigid layer). The type of coal conveyor belt (mining, power plant, large inclination, etc.) is directly related to its thickness range and composition. The actual selection needs to be considered in combination with the conveying capacity, material characteristics and equipment parameters.