How much can belt conveyor output be?

News 2025-05-06

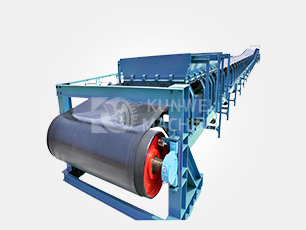

How much can belt conveyor output be? In fact, the output size of a belt conveyor is affected by a combination of factors, mainly including the following aspects:

1. the parameters of the belt conveyor itself

Belt width: the larger the width, the larger the cross-sectional area of the material that can be carried, the higher the theoretical output.

Belt speed: the faster the belt runs, the more material is conveyed per unit time. The output is usually proportional to the belt speed.

Groove structure: the groove shape of the belt (flat or groove) affects the cross-sectional area of the material accumulation, groove belt can be loaded with more materials.

2. Material Characteristics

Bulk density: For example, the greater the bulk density of coal, the greater the mass conveyed in the same volume.

Particle size and humidity:

Material particle

particle size is too

Large or high humidity may lead to poor fluidity of the material, affecting the loading efficiency or causing blockage.

High humidity may increase the viscosity of the material, leading to belt sticking or cleaning difficulties.

3. Drive and power

Motor power: Insufficient drive power may cause the belt to be unable to reach the designed speed or the load capacity is reduced, limiting the output.

Transmission efficiency: the loss of transmission parts such as reducer and coupling will affect the actual output power.

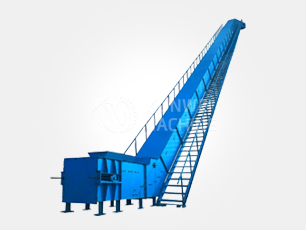

4. Inclination angle

Belt inclination angle: the greater the inclination angle, the easier the material slips, the need to reduce the belt speed or reduce the loading capacity to maintain stability, resulting in a decline in production.

5. Operating conditions

Continuous running time: Frequent starting and stopping or malfunction stopping directly reduces the effective operating time and affects the total output.

Load uniformity: Uneven distribution of materials may lead to local overload or belt deflection, reducing transportation efficiency.

Roller and Drum Condition: Worn or faulty rollers/drums can increase running resistance, reduce belt speed or cause downtime.

6. Environmental Factors

Temperature: Extreme temperatures can affect belt material properties (e.g., elasticity, coefficient of friction).

Dust and corrosion: Harsh environments accelerate equipment wear, increase maintenance frequency, and indirectly affect output.

The above six is the six main factors affecting the belt conveyor conveyor larger, but its from the initial design and later maintenance are not detached from the belt machine resulting in long-term use of the effect. For example, the theoretical design rationality, such as the center distance between the head and tail wheel, tensioning device design to match the actual demand; and maintenance, for example, the need to regularly clean up the accumulation of material, adjust the tension, replacement of worn parts to maintain efficient operation of the equipment; increase belt speed or widen the belt (need to synchronize with the upgrading of the drive power); to improve the fluidity of the material (such as controlling the humidity, to reduce the large pieces of material); regular maintenance of the equipment, to reduce non-scheduled Optimize loading methods to ensure uniform material distribution.