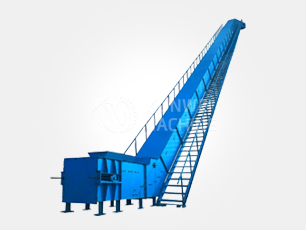

How many degrees of belt conveyor with non-slip belt?

News 2025-05-06

How many degrees of belt conveyor with non-slip belt? This question is actually mainly related to the material, sometimes even if the angle of inclination is not big, it is also necessary to use anti-skid conveyor belt.

For example, common materials, such as coal, sand and gravel. General ≤ 18 ° ~ 20 °: usually can use the smooth belt (no anti-skid design); angle > 20 ° need to use anti-skid measures, such as: patterned belt (herringbone pattern, v-shaped pattern, etc.) for 20 ° ~ 30 ° incline; corrugated edge belt (plus side baffle and cross partition) can be used for 30 ° ~ 90 ° vertical feeding use.

If the material is highly fluid, such as calcium oxide, gypsum, sludge powder or fine particles, even if the angle is small (such as more than 15 °), it may also need non-slip belt, according to the material friction coefficient to determine.

Comprehensive view, how many degrees of belt conveyor with anti-skid belt? Is to be based on the material characteristics, such as particle size, humidity, friction coefficient; belt material, such as rubber pattern belt, corrugated baffle belt, as well as smooth conveyor belt, etc., the surface friction performance is different; operating conditions: speed, load, ambient temperature and humidity, and so on. Can not be a single only look at a certain item, need to be considered comprehensively for selection.