Belt conveyor anti-run-off switch is self-contained?

News 2025-05-06

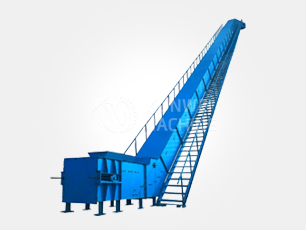

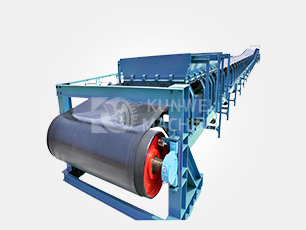

Belt conveyor anti-run-off switch in fact, in general, usually does not belong to the equipment comes with the standard components, but according to the actual needs of additional optional and installed safety protection devices.

So let’s first understand its role is what, in what circumstances need to install the belt conveyor anti-run-off switch?

Anti-run-off switch is mainly used for real-time monitoring of the running track of the conveyor belt, when the belt deviation occurs, through the two-stage triggering mechanism (a police, two stop) to prevent equipment damage or material spills. This kind of device is vital to guarantee production safety and prolong equipment life, but its installation needs to be decided according to specific working conditions.

Installation is generally installed in pairs on both sides of the conveyor belt, usually located in the head of the conveyor, tail, convex / concave arc section and the middle of the position, long-distance conveyor also need to be installed every 30-35 meters an additional pair.

The axis of the vertical roller should be perpendicular to the edge of the belt, and the belt should be located at one-third of the height of the vertical roller, and the spacing is usually 50-100mm.

The specific number of installation should be adjusted according to the length, type and layout of the conveyor, at least 3 pairs are needed for short conveyor and more for long distance.

Special attention should be paid to debugging after installation to ensure that the trigger angle and signal output are normal. For example, the first offset trigger alarm, the second offset trigger shutdown, troubleshooting vertical roller can be automatically reset. Daily maintenance should pay attention to waterproof and dustproof, and regularly check the status of wiring and mechanical components.