Is the belt speed of a belt conveyor proportional to the capacity?

News 2025-05-06

Is the belt speed of a belt conveyor proportional to the volume conveyed? If the answer is rigorous, must be whether! First we can analyze the structure of the belt conveyor itself:

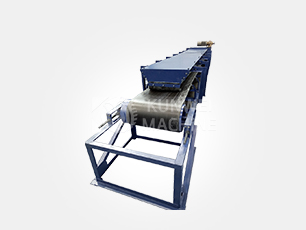

Take our commonly used belt conveyor as an example, tape, rollers, rollers, brackets, hoppers, etc. as the main components, but also according to the bandwidth, length, and site construction requirements to see if you need to increase the guardrail, sealing cover, cleaner and other accessories part.

And the part related to the belt speed is the first part of the conveying capacity, and the conveying capacity needs to be combined with the actual working conditions of the site needs to be designed. What we need to understand is

1. Material conditions – what materials, particle size, the site wants to achieve the conveying capacity is how much (preferably can be combined with the upstream and downstream equipment processing capacity design);

2. The site conveying angle – affecting the selection of the type of belt conveyor. For example, below 28 degrees, it is recommended to choose TD75 or DTII type belt conveyor; above 28 degrees, it is recommended to choose DJ large inclination belt conveyor.

According to the above two select the appropriate mode of transportation, and then determine the belt conveyor bandwidth, belt speed can meet the above requirements of the conveyor. The reason why the belt conveyor is so effective in heavy industry is because as one of the non-standard customized equipments, each production of the belt conveyor is combined with the actual situation of the site for the design of a one-to-one program to meet the requirements of different site conveyance, in order to achieve the desired conveying effect of each site!