Belt machine operating steps and procedures

News 2025-05-06

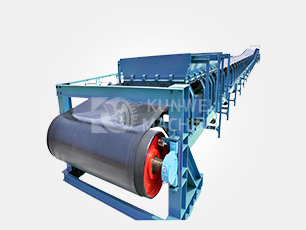

Belt machine operation steps and procedures are crucial in industrial production, they ensure efficient and safe material transportation. After completing the initial inspection and preparation of the belt conveyor, the next step is to enter the formal operation process.

First, start the power supply of the belt conveyor and observe whether the indicator light on the control panel is on to confirm that the equipment is energized. Subsequently, press the start button, the belt machine will start slowly, at this time should pay close attention to the running of the belt to ensure that it is smooth and no jitter. If you find any abnormal sound or belt running phenomenon, you should immediately stop the machine to check and troubleshoot before starting.

After the belt machine is running stably, you can start to adjust the speed of material conveying. Through the speed knob on the control panel, gradually adjust the running speed of the belt conveyor according to the production demand. During the adjustment process, it is necessary to maintain an even distribution of materials on the belt to avoid piling up or slipping to ensure the conveying efficiency.

In addition, the tension of the belt machine needs to be checked regularly. If the belt is too loose, it may lead to slippage or increased wear; if it is too tight, it may increase the load of the motor and affect the life of the equipment. Therefore, the belt tensioning device should be adjusted at the right time according to the actual situation to keep it in the best condition.

During the operation of the belt machine, the operator should always be vigilant and ready to deal with possible emergencies. Once the material blockage, belt breakage and other emergencies are found, the stop button should be pressed immediately, cut off the power supply, and take appropriate emergency measures to deal with.

Finally, when the production ends or when it is necessary to shut down for maintenance, the belt conveyor should be gradually shut down according to the specified procedures to ensure the safe shutdown of the equipment. At the same time, the belt machine should be fully inspected and maintained to be ready for the next use.