Why are enclosed belt conveyors recommended for powders?

News 2025-05-07

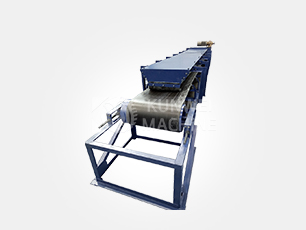

Why are enclosed belt conveyors recommended for powders? This brings us to its dust control and environmental protection! ~

Powder, especially fine granular materials, in the transmission process is very susceptible to external wind effects, resulting in dust pollution, not only endangering the health of workers on site, but also irreversible damage to the environment. The closed belt conveyor’s fully enclosed design effectively isolates the material from direct contact with the outside environment, greatly reduces the dispersion of dust, protects the air quality of the production site, and meets the increasingly stringent national and local environmental standards.

Closed belt conveyor also shows unique advantages in improving production efficiency and guaranteeing material quality. Its continuous and stable transmission reduces the production interruption and cleaning work caused by material spilling and piling, and significantly improves the production efficiency. At the same time, the closed environment can also effectively prevent the intrusion of moisture, impurities and other external factors, to maintain the dryness and purity of the powder, which is undoubtedly a major gospel for the chemical industry, heavy industry coal yard with strict quality requirements for conveying coal powder, aluminum powder class! ~

Enclosed belt conveyor model selection, but also more abundant ~ can have multiple choices, according to the horizontal, inclined, vertical three kinds of conveying angle for the selection of belt conveyor models, respectively, TD75 type and DTII, DTII (A) for the can be horizontal can be tilted belt conveyor, these three types of models collectively referred to as the groove type belt conveyor; need to be vertical or a large angle of inclined feeding, you can choose the DJ-type, that is, the large angle of inclination of the belt Conveyor. The above four models can be sealed in various forms, such as fully enclosed or semi-enclosed, in order to achieve the function of dustproof and rainproof or environmental protection!

Finally the most important thing is actually from a business or from the point of view of project cost control. Although the initial investment in a closed belt conveyor may be slightly higher than traditional open equipment, its reduced maintenance costs, cleaning costs and fines that may be faced due to environmental violations make the overall operating costs significantly lower. More importantly, it establishes a good environmental image for the company, which helps to attract more customers and partners who focus on the concept of sustainable development. So each enterprise or project to develop, to be more discretionary Oh! ~