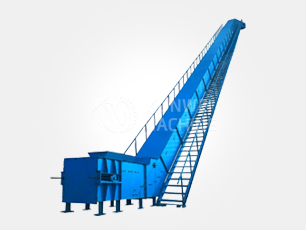

Belt conveyor how to adjust the tape elasticity

News 2025-05-07

How to adjust the tape tightness of belt conveyor? In daily maintenance, adjusting the belt tightness is a crucial task, which is directly related to the operating efficiency and stability of the conveyor. When the tape is found to be too tight or too loose, timely measures must be taken to adjust, in order to avoid unnecessary wear and tear, increased energy consumption and even equipment failure.

First of all, check and confirm whether the driving device and tensioning device are in good working condition. Tensioning device, such as hammer type, spiral type or hydraulic type, etc., is the key component for adjusting the tightness of the tape.

Different forms of tensioning require different adjustment methods. Hammer type tensioning device can be adjusted by increasing or decreasing the weight of the hammer to adjust the tape tension; spiral type tensioning device can be adjusted by rotating the adjusting screw to change the position of the tensioning roller to adjust the tape tension; hydraulic type tensioning device can be precisely controlled by adjusting the pressure of the hydraulic system.

In the adjustment process, should be carried out gradually, each time to adjust a small distance or increase or decrease the appropriate amount of weight, and then observe the tape running situation. Ideally, the tape should be kept at the proper tension when empty and fully loaded, neither too tight to cause increased wear, nor too loose to cause slippage or run-off. In addition, you also need to pay attention to check whether the tape deflection, because deflection is also a manifestation of the tape tension is not appropriate, need to be corrected in time by adjusting the rollers, sweepers and other components.

After completing the adjustment, test run should be carried out to observe whether the tape runs smoothly and whether there is any abnormal vibration or noise. At the same time, it is also necessary to regularly test the tension of the tape to ensure that it remains stable during long-term operation. This can not only effectively extend the service life of the belt conveyor, improve its working efficiency, and provide a strong guarantee for the production and operation of the enterprise.