What are the shafts of a stranded screw conveyor

News 2025-05-07

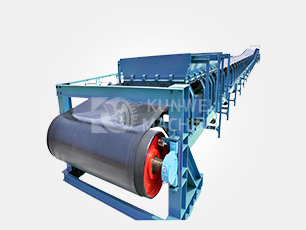

Screw conveyor, just from whether there is a center shaft to classify, can be divided into two kinds of shaft, no shaft. But if you want to ask what are the shafts of the screw conveyor, it can be more than just the center shaft.

First, the head and tail bearing

The head and tail bearings of the screw conveyor are supported by thrust bearings and radial bearings. Thrust bearings generally use tapered roller bearings, thrust bearings can withstand the axial force of the screw shaft conveying materials.

Set at the end of the head section can make the screw shaft only subject to tensile force, this force state is more favorable. The thrust bearing is installed on the end plate of the head section trough. It is also the support frame of the screw shaft. The main difference between the tail section device and the head section device is that the double-row centripetal spherical bearing or sliding bearing is installed on the end plate of the tail section trough.

Intermediate bearings/Hanging bearings

When the screw conveyor is too long, it is generally assembled in the form of multiple sections, and when it exceeds 3-4 meters, it should be equipped with intermediate bearings, which are also called suspension bearings, and their main function is to bear part of the weight of the screw shaft and the force generated during the operation. The upper part of the intermediate bearing is suspended on the transverse slats, and the slats are fixed on the flange of the trough or its reinforcing angle, so it is called suspension bearing, also known as hanging bearing. There are many types of suspension bearings.

Due to the interruption of the spiral blade at the suspension bearing, the material is easy to accumulate here, so the size of the suspension bearing should be the most compact. And can not be installed too dense, generally every 2-3m long to install a suspension bearing. The standard length of a section of the screw is 2-3m, to connect several sections of the standard screw into the length required by the process, the connection of each section of the screw conveyor is dependent on the screw conveyor suspension bearings, connecting shafts and shaft tiles are easy to damage the components, should be set up sealing and lubrication devices in order to minimize its wear.