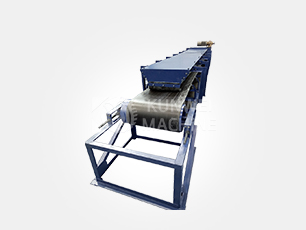

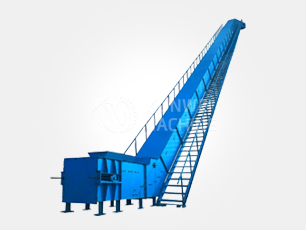

How often is it good to repair a large incline belt conveyor?

News 2025-05-09

In fact, some users have asked me more than once, how often should the large inclined belt conveyor be repaired? From the practical application of the effect, on time to the large inclined belt conveyor for the whole body repair work can indeed extend the service life of the large inclined belt conveyor, so like the large inclined belt conveyor inspection of a class of work, it is recommended that every day to be carried out. The repair work of the large inclined belt conveyor, generally speaking, large inclined belt conveyor maintenance of different categories, maintenance categories of different corresponding maintenance cycle is not the same, so according to different repair standards, the time spent is not the same, so according to different repair standards, large inclined belt conveyor maintenance personnel will be divided into repair work and overhaul.

First, small repair work time is not fixed

For the small repair work of large inclination belt conveyor, in fact, the maintenance cycle is generally not fixed. That is to say, the need for irregular inspection, usually new to the large inclined belt conveyor, the maintenance cycle can be longer, but whether it is new to the large inclined belt conveyor or the use of longer large inclined belt conveyor small repair projects are the same, that is, to check the joints of the belt, check the roller and the rollers, check the triangle belt, chain, gears, transmission structure, and so on, and at the same time need to do a good job in the parts of the cleaning and Refueling work.

Second, overhaul work is generally 12-18 months

For the overhaul of the large inclined belt conveyor, it is generally recommended to overhaul every 12-18 months, of course, the new large inclined belt conveyor overhaul project maintenance cycle can be a little longer. Overhaul project main overhaul content in addition to include the above small repair items, but also need to decompose and check each roller and bearing and transmission system is normal, do the corresponding cleaning work, the connection part of the oil change operation. Check and adjust the belt cleaner, check whether the discharging hopper is normal or not, deal with the wear and tear of the belt and side skins, adjust the belt’s tension, replace the belt if it is worn out, and correct the deviation of the drive roller and the rollers, and so on.

In addition, I would like to interject that we should not only carry out maintenance work on time, but also carry out strict maintenance assessment standards. Because this will not only be large inclined belt conveyor problems may occur as early as possible to find as early as possible to deal with, extend the use of large inclined belt conveyor cycle, but also to avoid large inclined belt conveyor staff in the maintenance process because of the neglect of a series of problems caused by.