What are all the ways to prevent belt breakage of climbing belt conveyor?

News 2025-05-10

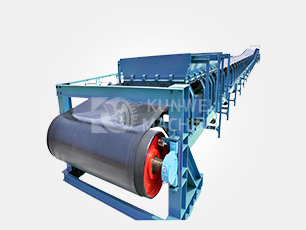

In the previous articles I said about the climbing belt conveyor prevention of belt breakage method, I have already posted on the platform before. Then I realized that I was just talking about the prevention methods of the climbing belt conveyor brother general-purpose belt conveyor. In fact, the methods are universal, but in view of some users really do not know where to look, so this article will again tell you about the climbing belt conveyor to prevent belt breakage methods are what?

First, before starting or after stopping to check the machine

Before starting or after stopping the machine to check, seemingly unnecessary step, in fact, to be honest, this step is really very very important. Because most of the broken belt conveyor climbing belt conveyor is actually because the climbing belt conveyor in the running process mixed into the sharp metal objects, resulting in metal objects scratching the conveyor belt, which led to the climbing conveyor belt broken. So that before starting or after the shutdown of its inspection, really can prevent eighty percent of this similar situation occurs.

Second, regular maintenance of the whole machine, and create a strict maintenance system

From the perspective of professional manufacturers engaged in climbing conveyor, as well as according to user feedback, climbing belt conveyor the reason why the phenomenon of belt breakage occurs, to a large extent, climbing belt conveyor is a part of the fault, common problems with the rollers, roller problems, etc., so be sure to climb the whole belt conveyor maintenance, in a timely manner, easy to cause belt breakage and other phenomena such as belt failure exclusion.

Third, timely replacement of the conveyor belt

Usually the ideal service life of the climbing belt conveyor belt for 8-10 years, but we also said that this is the ideal state. The fact that the working environment of the climbing belt conveyor is complex, overloaded work, coupled with the improper use of staff and other factors will affect the life of the conveyor belt, so when your climbing belt conveyor conveyor belt reaches a certain age should be replaced in a timely manner to prevent the phenomenon of belt breakage.

Fourth, the installation of iron removal devices and conveyor belt longitudinal tear protection devices

The solution to the conveyor belt breaks in addition to the operator on time to pay attention to the other, some auxiliary devices can also play a lot of role. Common devices are conveyor belt longitudinal tear protection device and iron removal device. The iron removal device is simply like a big magnet, which can effectively suck up the metal objects hiding in the material. The belt longitudinal tear protection device is simply an emergency stop to minimize the damage when the belt may be torn longitudinally. Iron removal device and longitudinal tear protection device, a spear and a shield attack and defense, minimize the slope climbing belt conveyor may occur belt breakage accident.

Fifth, start and stop the stress should be controlled in the ideal range

Why start and stop the stress should be controlled in the ideal range? On the one hand, the operator training degree is not the same, there is no good operating habits, on the other hand, in the climbing belt conveyor startup failed to start or no-load stop caused by stress changes, it is very easy to break the belt phenomenon, so in order to put an end to this phenomenon, we must be on time to the staff training, and strictly require them to operate the startup and stopping when the stress is controlled within the ideal range, and Conduct the relevant training test on time to ensure that everyone can memorize the

Translated with DeepL.com (free version)