Routine inspection and maintenance of belt conveyor conveyor belt

News 2025-05-10

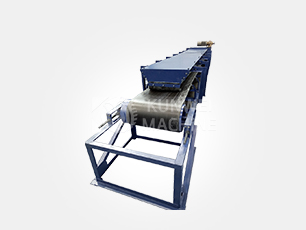

Why is it important to maintain the conveyor belt in a belt conveyor? In fact, it is necessary to talk about the components of the belt conveyor. Usually the belt conveyor has a driving device, conveyor belt, rollers, pulleys and safety protection devices and other components. In these parts, only the conveyor belt and drive the most important, of course, I say this does not mean that the rollers, pulleys and other parts are not important, they are also an indispensable part of the belt conveyor. Just conveyor belt and drive relative to other parts is too important, especially the conveyor belt, which can be seen from the first two words of the belt conveyor, it in the end how important.

Say a thousand words, in a word, the belt conveyor conveyor belt is not the eight-pack abs of the brown man, but more like a dainty, soft and weak little male. This I think the belt conveyor users should have more experience than me, to give a more realistic example, like the belt conveyor often encountered failures, belt conveyor deflection, belt conveyor longitudinal tear, belt conveyor slipping and so on a series of problems, are related to the conveyor belt. Even the belt conveyor protection devices to protect the conveyor belt devices are: anti-skid protection devices, iron removal devices, anti-bias devices and anti-tear protection devices. It can be seen that even the designers of the belt conveyor know that the conveyor belt is a delicate little male, need to focus on protection.

Belt conveyor in addition to the need for key protection devices, the daily maintenance of the belt is equally important, then this article to talk about the daily maintenance of the belt conveyor what are?

Regular inspection and maintenance of conveyor components

First, check the conveyor belt deflection

In fact, the reason for the frequent occurrence of belt conveyor failure problems, to a large extent, are caused by the conveyor belt deflection, because the conveyor belt deflection will not only cause irreversible damage to the conveyor belt, but also cause a lot of economic losses, so in order to avoid a series of problems such as the conveyor belt deflection, so we also need to check the phenomenon of conveyor belt deflection on a regular basis, and timely adjustments.

Second, check the periphery of the conveyor belt with or without hard metal objects

I think this is a very important step, like the longitudinal tearing of the conveyor belt is actually the earliest time may be due to the conveyor belt around the hard metal objects scratches lead to, in fact, this is also the most labor-saving way of maintenance, even after the belt conveyor shutdown, by the way turn, by the way to look at the belt conveyor can be avoided to appear hard metal objects scratches conveyor belt occurs.

Third, the width of the receiving end of the loading chute should be large enough

From the practical application effect, the bearing point is undoubtedly the vulnerable parts of the conveyor belt. Conveyor belt speed, material block direction and impact is an important factor affecting conveyor belt transportation, so the width of the receiving end of the loading chute should be large enough.

Fourth, check the conveyor belt and its cycle material residue situation

This point must not need me to parse more, I went to kindergarten little brother know that after meals to wipe their mouths, after the toilet to wash their hands. As a belt conveyor staff, should know to keep the roller and roller surface clean, keep the return roller and buffer roller clean and the conveyor belt is clean when entering the return operation.

Fifth, check out the damaged rollers to replace the rollers in a timely manner

In the daily inspection of the conveyor belt, should ensure that the upper and lower rollers in line with the management requirements of the rollers, timely repair or replacement of damaged rollers.

Sixth, timely check the tensioning device

In the daily inspection of the conveyor belt, should check whether the tensioning device can move, the size of the trip, the sliding condition of the guide frame is good, regular oil filling, and check the cover plate set in the tensioning device to prevent the material from falling in.

Seven, timely check the wear and tear of the conveyor belt

Regularly check the conveyor belt, if there is early rubber sleeve damage and belt edge wear, it should be excluded in time.