What should I pay attention to the belt speed of the belt conveyor?

News 2025-05-10

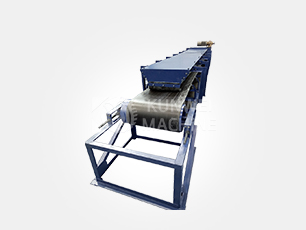

Usually, the conveying capacity is determined by the requirements of the engineering system, which simply means that the conveying capacity is decided according to the user’s demand, and the belt conveyor should be able to complete the required conveying capacity, in which the designer should choose the suitable idling speed and bandwidth according to the user’s demand. This article will introduce in detail what should be paid attention to the belt speed of the belt conveyor?

First, how to choose idle speed

Belt speed depends largely on the characteristics of the material to be conveyed, the desired conveying capacity and the tension of the conveyor belt used. So the specific selection of belt speed must be communicated with the designer in time, and the desired conveying capacity and the adopted conveyor belt tension will be told to the designer in time, so that the suitable belt speed can be selected.

What belt speed should be used for powdery materials?

Powdery materials should be conveyed at a low enough belt speed to minimize dust, especially at the loading and unloading points. Fragile materials will also limit the belt speed. When the conveyor belt and conveyed material through the rollers, the lower belt speed can make the fragile material in the loading and unloading point does not occur at the jump broken.

Third, very heavy, sharp-edged materials should take what belt speed

Heavy materials with sharp edges should be conveyed at a medium belt speed, because the sharp edges of the materials will excessively wear the surface layer of the conveyor belt, especially when the loading speed is significantly lower than the speed of the conveyor belt in the conveying direction.

Fourth, high idle speed conveying should pay attention to what

In the more favorable loading and operating conditions, for the bandwidth is not greater than 800mm belt conveyor, can be used with a belt speed of 3m/s to convey powder, wet sand, no large pieces of soil and crushed stone. And increasing the belt speed can reduce the bandwidth and conveyor belt tension. However, in bringing the above benefits at the same time, but also need to weigh the possible wear and tear of the conveyor belt, material jumping, air resistance, bearing rollers large block impact and so on the aggravation and conveyor belt all parts of the life of the reduction of shortcomings, so in the use of high belt speed conveying, the designer should be carefully studied to ensure that the program’s feasibility, and what may happen to tell the user in a timely manner.

Fifth, the unloading method should also be considered

The design of the feeding zone and the head of the drum unloading method in the choice of idle speed must also be considered. If the material is dry and powdery, when the belt speed is very high, the dust of the material will be unbearable. If the material is heavy and contains large chunks, or if the edges of the particles are angular and sharp, high discharge speeds can cause excessive wear on the discharge chute or transfer chute.