Belt Conveyor Troubleshooting Quick Repair Collection

News 2025-05-10

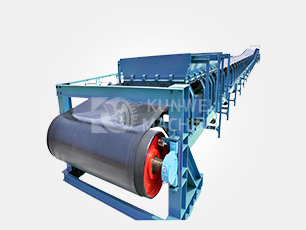

Belt conveyor simply includes TD75 belt conveyor and DTII belt conveyor, DTII (A) type belt conveyor and large inclination belt conveyor, it can also be said that the above four types of conveyors collectively referred to as the belt conveyor, which due to the TD75 belt conveyor and DTII type belt conveyor, DTII (A) type belt conveyor is transported in the plane, and each other and the general-purpose belt conveyor. Can be generalized, so also known as general-purpose belt conveyor. But no matter what kind of belt conveyor for the user he is happy how the belt conveyor can create greater value for them, unhappy is the belt conveyor failure.

In fact, it is reasonable to say that the machine failure is normal, after all, the human evolution of hundreds of thousands of years or inevitably sick, not to mention the belt conveyor to the present is only a district of more than a hundred years. Just as a person is sick, we must hurry to cure, to prevent further deterioration of the same, belt conveyor failure should also be repaired in a hurry. Of course, not everyone is a maintenance expert, but for some of the more common failures of white people can also be quickly repaired, then today we will talk about the belt conveyor failure fast repair collection.

First, the belt offset problem

Solution: the belt deflection occurs for many reasons, when the belt offset, technicians should first reasonably debug the structure of the rollers, and do a good job of adjusting the level and balance of the roller. Then debug the position of the roller round axis in the head and tail of the machine, and debug it precisely according to the requirements of the normative installation standards. In addition, strengthen the inspection of the joints and roller bearings of the belt conveyor, make an objective assessment of the wear condition, and replace the excessively worn parts in time. And the speed and angle of loading are reasonably debugged to ensure that the weight of raw coal can be well balanced on the belt conveyor.

Second, belt breakage problem

Solution: Timely installation and replacement of the aging belt, in the daily use of management belt conveyor process, should strengthen the belt life concern, build a perfect belt replacement mechanism.

Third, the handling of material and abnormal shaking problems

Solution: Belt conveyor material and abnormal shaking problems, mostly in the general-purpose belt conveyor, the solution is very simple, material and abnormal shaking most of the material for a part caused by just find the faulty parts in time to replace the parts, and do a good job of connecting the installation can be.

Fourth, the reducer broken shaft problem

Solution: In the event of broken shaft failure, first of all, the equipment should be blackout, disassemble the gearbox for a comprehensive inspection to ensure that there are no other failure points in addition to the broken shaft, reinstallation of the new shaft should be fully fastened after all fasteners, carefully calibrate the installation distance to ensure that the shaft is centered on the bearings and other key parts of the connection to supplement the lubricating oil, and then carry out the test on the power supply.

V. Handling of oil leakage problem of reducer

Solution: professional and technical personnel to check the heat treatment and quality of the reducer, and the heat exhaust device and the number of exhaust holes to increase the appropriate number of reducer heat dissipation, heat-resistant ability to improve. At the same time should strengthen the belt conveyor load management, so as not to shorten the service life of the reducer long-term high load operation.

Sixth, the noise problem

Drive and roller components are belt conveyor operation is prone to noise parts, staff can determine the source of noise equipment failure location, found after stopping to check, timely repair or replacement. Usually the noise problem is mainly caused by three aspects.

(1) The noise caused by the serious deviation of the rollers from the center.

Solution: staff in the maintenance of equipment in the process need to adjust the position of the rollers in a timely manner, the noise problem effectively resolved. If the equipment coupling axis is not centered will also lead to equipment noise, so the staff should also pay attention to adjust the coupling axis to ensure that it is in the same straight line.

(2) coupling problems caused by noise

Solution: Staff need to adjust the position of the motor and reducer in time to avoid the occurrence of shaft fracture affecting the safe use of equipment.

(3) Noise caused by bearing damage

Solution: The staff should strengthen the overhaul equipment, eliminate leaks in a timely manner, do a good job of lubricant replacement, if the more serious leaks then need to replace the bearings.

Seven, motor burnout

Solution:

(1) power quality reasons

If the quality of power caused by frequent motor burnout can be considered to increase the power supply capacity or a separate configuration of a dedicated line.

(2) cooling device performance decline

If the cooling device performance decline, should be timely replacement of the motor fan or increase the dust removal device, etc., to ensure that the motor windings get timely cooling.

Eight, roller damage

Solution: The problems caused by damage to the rollers are countless, so when the rollers are damaged, they must be replaced in a timely manner.