Belt Conveyor Component Names

News 2025-11-07

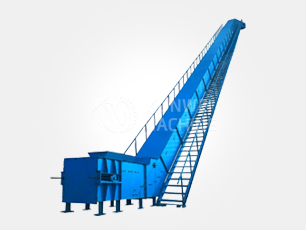

Taking trough belt conveyors as an example, there are three models: the TD75 belt conveyor, the DTII heavy-duty belt conveyor, and the DTII(A) deep trough belt conveyor (also commonly known as the V-type belt conveyor).

Belt conveyor components are broadly categorized into eight sections:

Belt Conveyor Component Names

1. Redirecting Drum: Primarily used to alter the conveyor belt’s running direction or to press the belt tightly against the drive drum, increasing its wrap angle.

2. Lower Parallel Idler: Supports and transmits the weight of the material, ensuring smooth movement.

3. Trough Idler: The trough angle for the TD75 belt conveyor is 30 degrees; DTII heavy-duty belt conveyors feature trough angles of 35 degrees or 45 degrees; DTII(A) deep-trough belt conveyors have trough angles of 50 degrees or 60 degrees.

4. Belt Frame: Constructed from carbon steel or stainless steel to support materials on the conveyor belt, ensuring stable operation and preventing material collapse or accumulation.

5. Electric Drum: Unlike conventional drums, this innovative drive unit integrates a motor and reducer within the drum body. Primarily used in fixed and mobile belt conveyors, it replaces traditional separate drive units where the motor and reducer are mounted externally to the drive drum.

6. Conveyor Belt: Constructed from black rubber, typically 4-ply with a 10mm thickness. Custom thicknesses are available upon request.

7. Hopper: The primary function of the receiving hopper is to ensure material accurately transfers from the head pulley of the preceding belt to the centerline of the tail section of the subsequent belt.

8. Scraper: Available in various types, all serving the same purpose. Primarily used to remove adhered material and debris from the belt surface. An effective cleaning system removes buildup from drum surfaces and the underside of the conveyor belt, preventing belt deviation, extending the service life of the belt and accessories, and mitigating accidents.