90 Degree Vertical Conveyor System for Chemical Plants | Kunwei

Eliminating Leakage in Chemical Plants with a 90 Degree Vertical Conveyor System

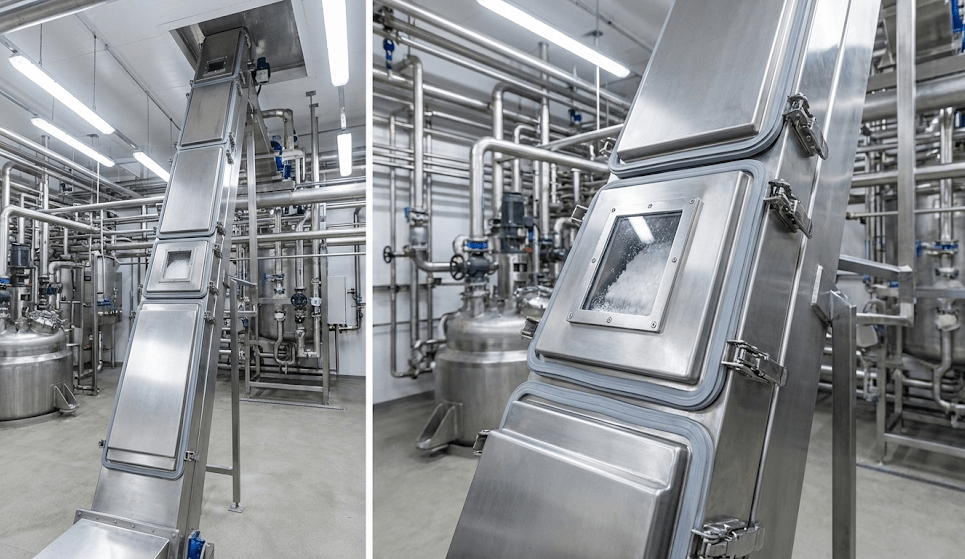

The direct answer is simple: a 90 degree vertical conveyor system for chemical plants is the most effective way to eliminate material leakage when handling corrosive chemical granules and hazardous pellets. In real chemical production environments, even minor leakage at transfer points can trigger environmental contamination, failed safety audits, and unplanned shutdowns. Kunwei Machine engineered the DJ Series closed-type sidewall conveyor specifically for these conditions. By combining a fully enclosed structural design with chemical-resistant materials, this system delivers true zero-leakage vertical transport while meeting the strict compliance standards required in modern chemical processing plants.

90 Degree Vertical Conveyor System for Chemical Plants

Scenario-Based Applications in Chemical Processing Plants

- Vertical Reactor Feeding: Controlled and sealed feeding of corrosive granules directly into reactors, preventing airborne dust and operator exposure.

- Hazardous Waste Enclosed Transfer: Safe vertical transport of by-products and off-spec pellets within a closed housing, reducing contamination risks during recovery or disposal.

- Dust-Free Cross-Workshop Lifting: Clean vertical elevation of chemical pellets between processing floors without releasing particulate matter into adjacent production areas.

Compared with traditional bucket elevators or open inclined conveyors, Kunwei’s closed-type sidewall system significantly mitigates material fallback and leakage. The enclosed design isolates the conveying path from the surrounding environment, reducing product loss while protecting personnel and equipment.

Technical Integrity of the DJ Series

| Belt Width (mm) | Max Inclination | Typical Capacity (t/h) |

|---|---|---|

| 500 | 90° Vertical | 30–80 |

| 650 | 90° Vertical | 60–150 |

| 800–1400 | 90° Vertical | 120–400 |

Engineering Logic: The gas-tight enclosure surrounding the belt path forms a controlled internal environment. This structure prevents vapor escape and particulate leakage, ensuring that volatile or high-value chemical materials remain fully contained throughout the vertical lifting process.

Engineering Logic & Material Selection

Material selection determines whether a vertical conveyor survives or fails in chemical service. Kunwei Machine specifies chemically resistant NBR or EPDM belt compounds to withstand aggressive media, while optional SS304 or SS316 stainless steel housings provide long-term corrosion resistance. These choices are not theoretical—they are based on years of field experience in fertilizer, polymer, and fine chemical plants.

From an engineering standpoint, the most critical factor is how the sidewalls and cleats are bonded to the base belt. Kunwei engineers apply integral hot vulcanization, fusing all components into a single structure. This method eliminates adhesive layers that can degrade under chemical attack, preventing sidewall detachment and ensuring consistent sealing performance over extended operating cycles.

Customization & Modular Design

- Explosion-proof drive motors for hazardous area classifications

- Nitrogen purge interfaces to support inert gas protection strategies

- Quick-open airtight inspection windows for safe monitoring and maintenance

Each DJ Series conveyor is configured as part of a broader system strategy. Kunwei Machine integrates these options into customized layouts, supported by our dedicated belt conveyor solutions hub.

Trust Signals & Quality Verification

Mini Case Study: A fertilizer granulation plant replaced an open bucket elevator with a Kunwei DJ Series closed-type vertical conveyor. Within three months, measured material loss dropped by 98%, housekeeping labor was reduced, and the plant passed its environmental compliance audit without corrective actions.

Expert Quality Check – Feed Point Sealing:

- Inspect the sealing skirt alignment at the feeding point. The skirt must maintain continuous contact with the belt surface to prevent material escape.

- Verify gasket compression consistency. Uneven pressure indicates potential leakage paths during vertical lifting.

- Observe material behavior under load. Proper sealing should eliminate visible fallback or dust emission at startup and shutdown.