Large Inclination Belt Conveyor for Limited Space

When Space, Not Capacity, Becomes the Bottleneck

A large inclination belt conveyor for limited space is often the only practical solution for vertical material lifting on urban construction sites.

Direct Answer

The DJ Sidewall Belt Conveyor is the only continuous conveying solution that can lift sand and gravel vertically at up to 90°, without requiring long horizontal run-up.

Urban Pain Point

If you manage a construction site in a dense city center, you already know the problem:

you don’t lack equipment — you lack space.

Traditional inclined belt conveyors are space-hungry by nature. Even with chevron belts limited to 18–20°, you still need tens of meters of horizontal length just to gain a few meters of height. In a downtown concrete batching plant squeezed between existing buildings, that footprint often simply doesn’t exist.

This is where a large inclination belt conveyor for limited space stops being an upgrade — and becomes a necessity.

Trust Signal

With true 90° vertical lifting capability, a DJ sidewall conveyor can reduce the conveying footprint by over 70% compared to conventional inclined belts, making it uniquely suitable for high-density urban infrastructure projects.

Solving Space Crisis with Large Inclination Belt Conveyor

Scenario: City-Center Concrete Batching Plant

Unlike open quarries or suburban plants, urban batching stations are usually constrained by:

– Narrow plots

– Fixed building envelopes

– Strict zoning and safety setbacks

Let’s look at a simple height requirement:

– Required lifting height: 10 meters

– Standard chevron belt (18° inclination):

– Required conveyor length ≈ 30 meters

– DJ vertical sidewall conveyor:

– Required length ≈ 2 meters (vertical column)

That difference is often the deciding factor between:

– ❌ Redesigning the entire plant layout

– ✅ Installing a compact vertical conveyor and keeping everything else intact

Material Suitability

Urban batching plants typically handle free-flowing materials such as:

– Sand

– Gravel

– Crushed aggregates

These materials are ideal for corrugated sidewall belt systems due to their predictable flow behavior and limited adhesion.

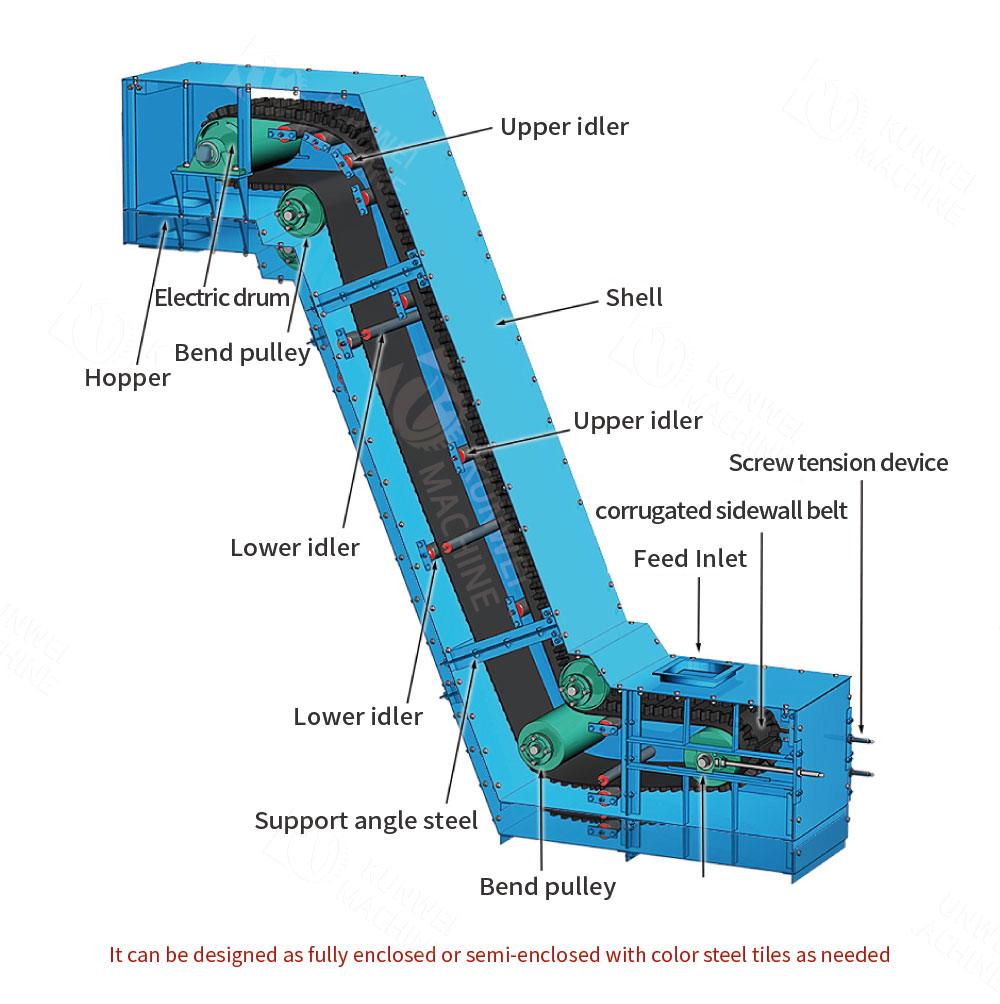

Technical Backbone: How It Lifts Vertically with Large Inclination Belt Conveyor

A vertical conveyor belt is not just a steep belt — it is a completely different structural concept.

Corrugated Sidewalls: Turning a Belt into a Box

The corrugated sidewalls act as flexible retaining walls, transforming the belt into a moving container that prevents material spillage even at extreme angles.

Transverse Cleats (TCS): The Load Carriers

The transverse cleats divide the belt into pockets, physically carrying the material upward rather than relying on friction.

For urban construction duty, this is critical:

– Gravity works against you at 90°

– Cleats must bear the full material load every cycle

Manufacturing Detail That Matters

High-quality DJ sidewall conveyors use hot vulcanization to bond cleats and sidewalls to the base belt.

This process ensures:

– No cleat peeling under heavy aggregate loads

– Long-term fatigue resistance in continuous operation

Sidewall Conveyor vs. Skip Hoist (The Real Trade-offs)

When vertical lifting is required, project managers often compare these two options.

Skip Hoist

Pros

– Simple structure

– Lower initial investment

Cons

– Intermittent operation

– Pulsed feeding to mixers

– Mechanical shock during start/stop cycles

DJ Sidewall Belt Conveyor

Pros

– Continuous material flow (e.g., up to 200 t/h)

– Smooth, consistent feeding for concrete mixers

– Lower operational vibration

Cons (Honest Disclosure)

– Higher requirements on base belt rigidity

– Maintenance cost can exceed flat belts if low-quality belts are used

Bottom Line

For urban batching plants prioritizing process stability and throughput, the DJ sidewall conveyor is usually the more professional solution.

Critical Quality Check: What Actually Determines Reliability

Vertical conveying leaves no room for weak components. Here are verifiable checks you can perform.

1. Cleat Rigidity Hand Test

Push a cleat by hand:

– It should resist bending under pressure

– Yet remain flexible enough to pass smoothly around pulleys

Too soft = material rollback

Too rigid = premature fatigue cracking

2. Base Belt Cross-Rigidity Test

Lift one edge of the empty belt:

– The opposite edge should lift simultaneously

– If it droops, the belt lacks cross-rigidity

A cross-rigid base belt prevents sidewall collapse under vertical load — a common failure point in low-cost systems.

Trust & Safety Considerations in Vertical Conveying

Vertical systems introduce unique risks that must be addressed openly.

– Backstop Device is Mandatory

In a fully loaded vertical conveyor, any power loss creates massive reverse torque.

A reliable backstop (anti-reverse) device is essential to prevent uncontrolled rollback.

– Carryback Risk (Material-Specific)

Note: For sticky or wet clay, sidewall belts may require specialized beater wheels for clean discharge.

Without them, carryback buildup becomes a real maintenance issue.

These are not flaws — they are engineering realities that must be designed for.

Conclusion: Buying Space with Engineering, Not Compromise

In urban construction, every square meter saved translates into:

– Easier approvals

– Faster installation

– Lower civil modification costs

A DJ large inclination sidewall belt conveyor allows you to trade vertical height for horizontal space — without sacrificing capacity or continuity.

If your project operates under tight spatial constraints, this is not an exotic solution.

It is the logical one.

CTA

– Request a Vertical Layout Drawing

– Get pricing for DJ-500 / DJ-650 / DJ-800 systems

For urban projects where land is expensive, a large inclination belt conveyor for limited space is not an option — it is a necessity.