The Heavy-Duty Standard for Mining, Ports, and Power Plants

Engineered for High Throughput. Built for Longevity.

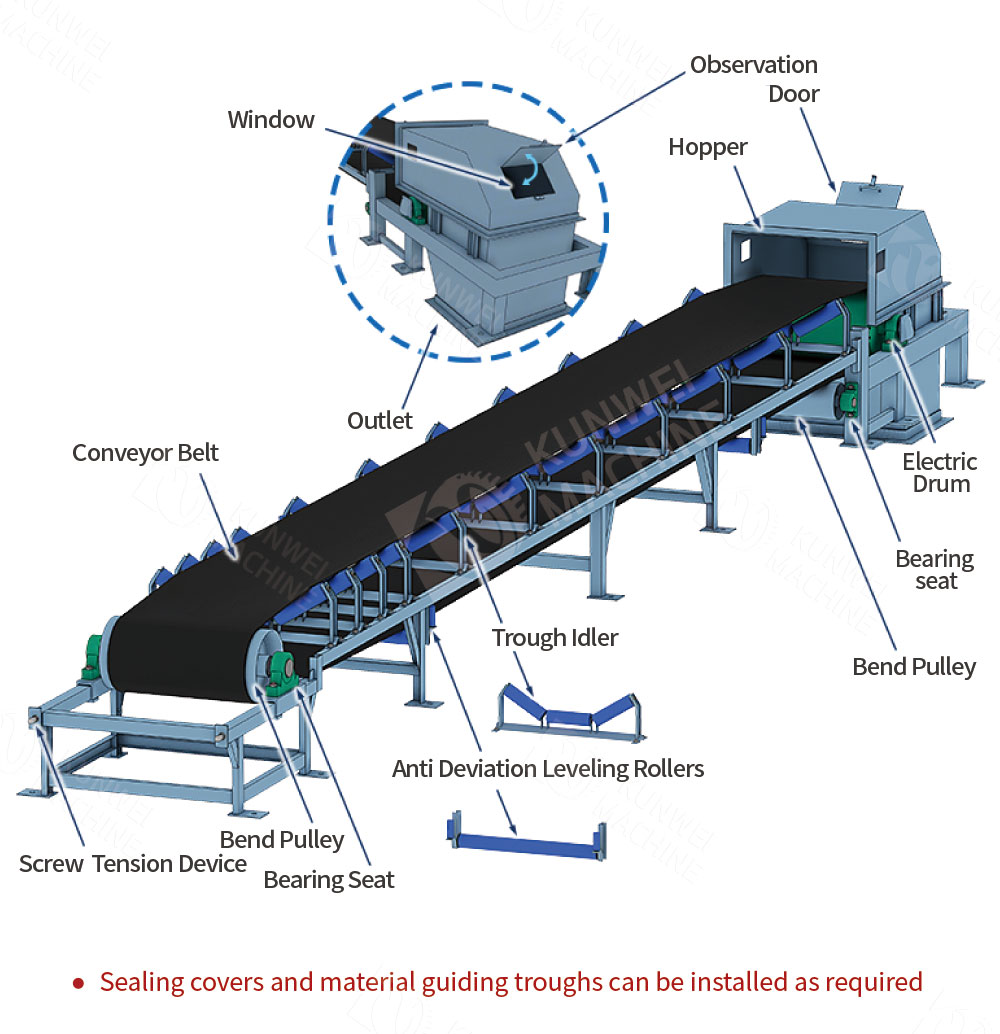

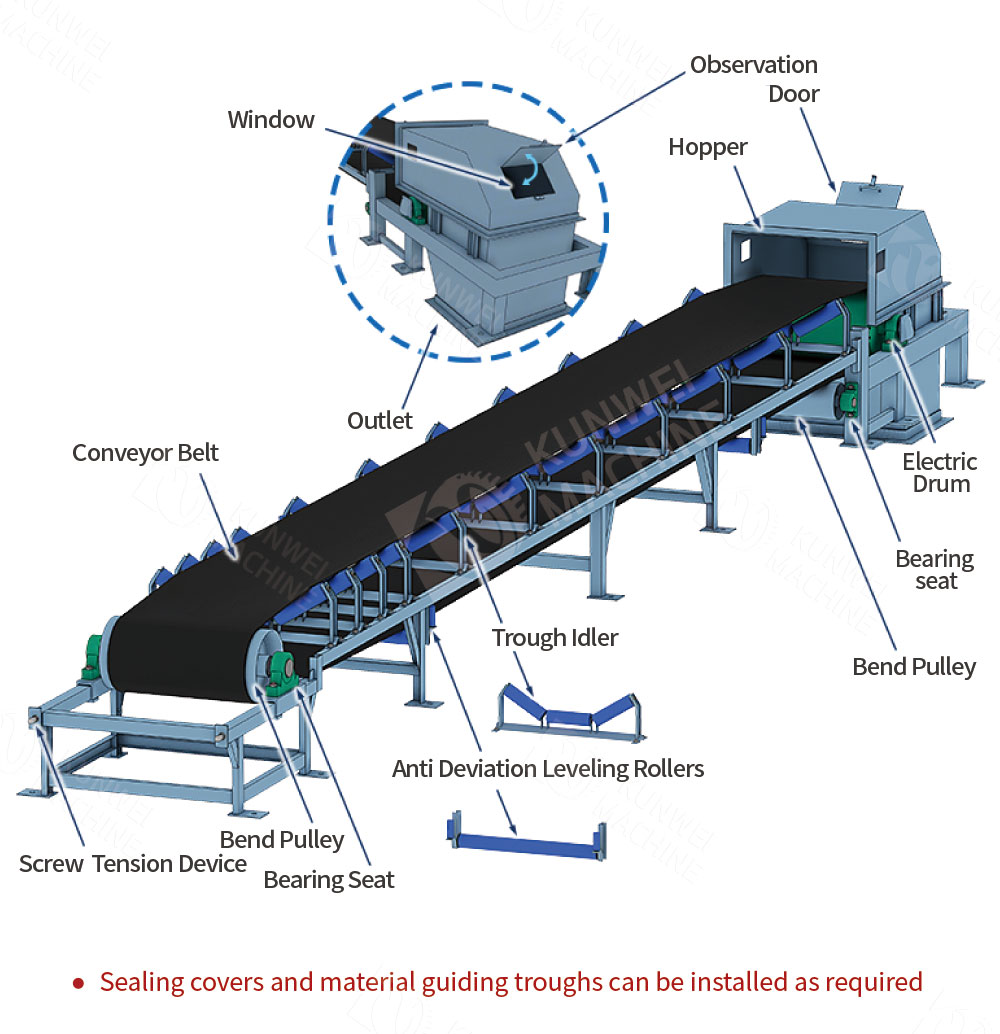

The DTII Fixed Belt Conveyor (including the upgraded DTII(A) series) is the definitive industrial standard for general-purpose bulk material handling. Designed to supersede the legacy TD75 models, the DTII utilizes a reinforced channel steel frame and advanced sealing technology to handle higher loads, wider belts, and longer distances without structural deformation.

If your operation demands continuous transport of iron ore, coal, aggregates, or grain at capacities exceeding 500 t/h, the DTII is the engineered solution for you.

Why Upgrade to DTII? (Technical Superiority)

The primary difference between a generic conveyor and the DTII lies in Structural Rigidity and Component Standardization.

Reinforced Frame: Unlike older systems using angle iron, the DTII uses channel steel or I-beam stringers. This resists twisting forces during start-up, preventing belt mistracking.

Advanced Sealing: Features idlers with non-contact labyrinth seals (water/dust proof) rather than simple metal shields, significantly extending bearing life in dusty environments.

Metric Standardization: The DTII(A) variant is fully ISO/DIN compliant, ensuring easy global sourcing of spare parts like pulleys, bearings, and motors.

Comparison: DTII vs. TD75

Make the right choice for your facility’s lifecycle costs.

| Feature |

TD75 Series (Legacy) |

DTII Series (Modern Standard) |

| Max Belt Width |

Up to 1400mm |

500mm – 2400mm |

| Structure |

Angle Iron (High flex) |

Channel Steel (High rigidity) |

| Speed Range |

< 2.5 m/s |

Up to 5.8 m/s |

| Ideal Use |

Light/Medium Industry |

Heavy Mining, Ports, Power |

| Maintenance |

Frequent Idler Failure |

Extended Service Intervals |

Core Applications

1. Open-Pit Mining & Mineral Processing

Transport crushed copper, iron ore, and gold concentrate. The system is compatible with impact beds to absorb the shock of heavy, sharp rocks (Density > 2.0 t/m³).

2. Thermal Power Generation

Safe handling of pulverized coal. Compatible with fire-retardant (FR) belting, enclosed galleries, and dust suppression hoods to meet environmental regulations.

3. Port & Terminal Logistics

High-speed overland conveying from ship unloaders to stockpiles. We offer Hot-Dip Galvanized frames to resist salt spray corrosion in seaside environments.

Technical Specifications Summary

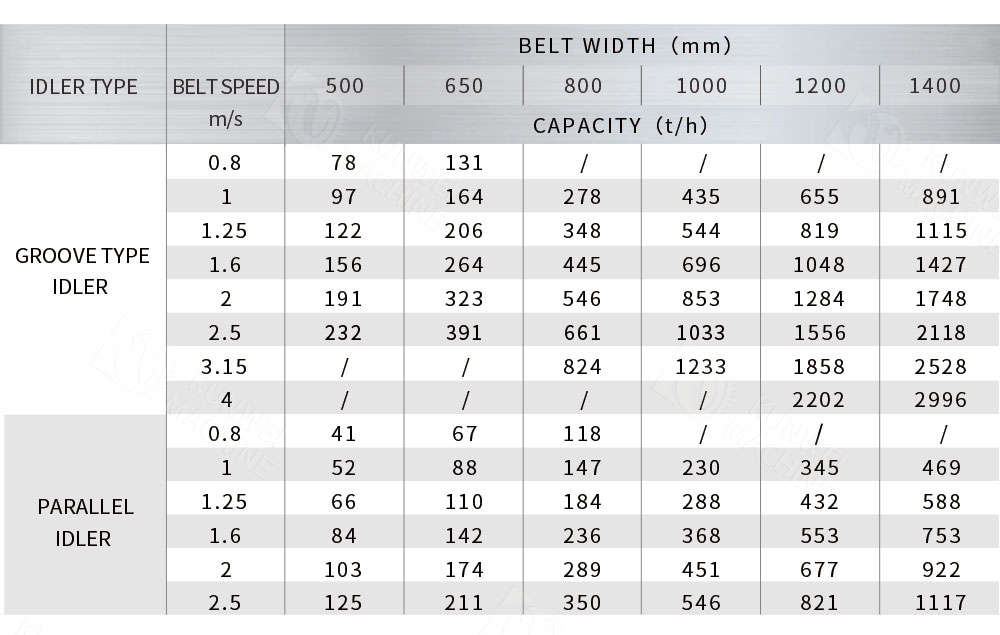

Belt Widths: 500mm, 650mm, 800mm, 1000mm, 1200mm, 1400mm, up to 2400mm.

Capacity: 50 t/h to 3000+ t/h (Dependent on material density and speed).

Belt Speed: 0.8 m/s to 5.0 m/s standard.

Drive Options: Electric Motor + Reducer / Electric Drum / Hydraulic Couplings for soft starts.

Tensioning: Vertical Gravity Take-up (recommended for long distances) or Screw Take-up.

Frequently Asked Questions

Q: Can the DTII conveyor be used for long-distance overland transport?

Yes. For distances exceeding 1km, we equip the DTII with intermediate drive units and steel cord belting to manage high tension.

Q: Do you provide the DTII or DTII(A) model?

We supply the DTII(A) as standard. This is the modernized version with improved bearing seals and metric dimensions. Legacy DTII parts are available upon request for repairs.

Q: What safety features are included?

All our systems can be configured with Pull Cord Switches (Emergency Stop), Belt Sway Switches, and Zero Speed Detectors to meet ISO safety compliance.

Ready to Configure Your System?

Don’t settle for under-specced equipment. Get a conveyor designed for your specific material and throughput.

Request DTII Specification Sheet & Quote