Product

Open Type Large Inclination Sidewall Belt Conveyor

Open Type Large Inclination Sidewall Belt Conveyor: The Ultimate Space-Saving Solution An open type large inclination sidewall belt conveyor is the ultimate space-saving solution for lifting bulk materials at steep angles, typically from 30° up to 90

Open Type Large Inclination Sidewall Belt Conveyor: The Ultimate Space-Saving Solution

An open type large inclination sidewall belt conveyor is the ultimate space-saving solution for lifting bulk materials at steep angles, typically from 30° up to 90°. By enabling near-vertical conveying, this system replaces long, shallow conveyors with a compact footprint—often the only practical option in space-constrained plants.

If you are running out of floor space for a traditional conveyor, or you need to lift coal, ore, or grain 20 meters high with only 10 meters of ground length, a sidewall belt conveyor directly addresses that constraint. Instead of adding multiple transfer points or complex civil structures, the conveyor creates a continuous, high-angle conveying path.

A key trust advantage is the open type design. Unlike enclosed pipe or tube conveyors, operators can visually inspect the belt, sidewalls, and cleats during operation. Maintenance teams gain direct access for adjustment and repair, which is critical in dusty mining sites or retrofit projects where downtime windows are short.

How High Angle Conveying Works (Technical Deep Dive)

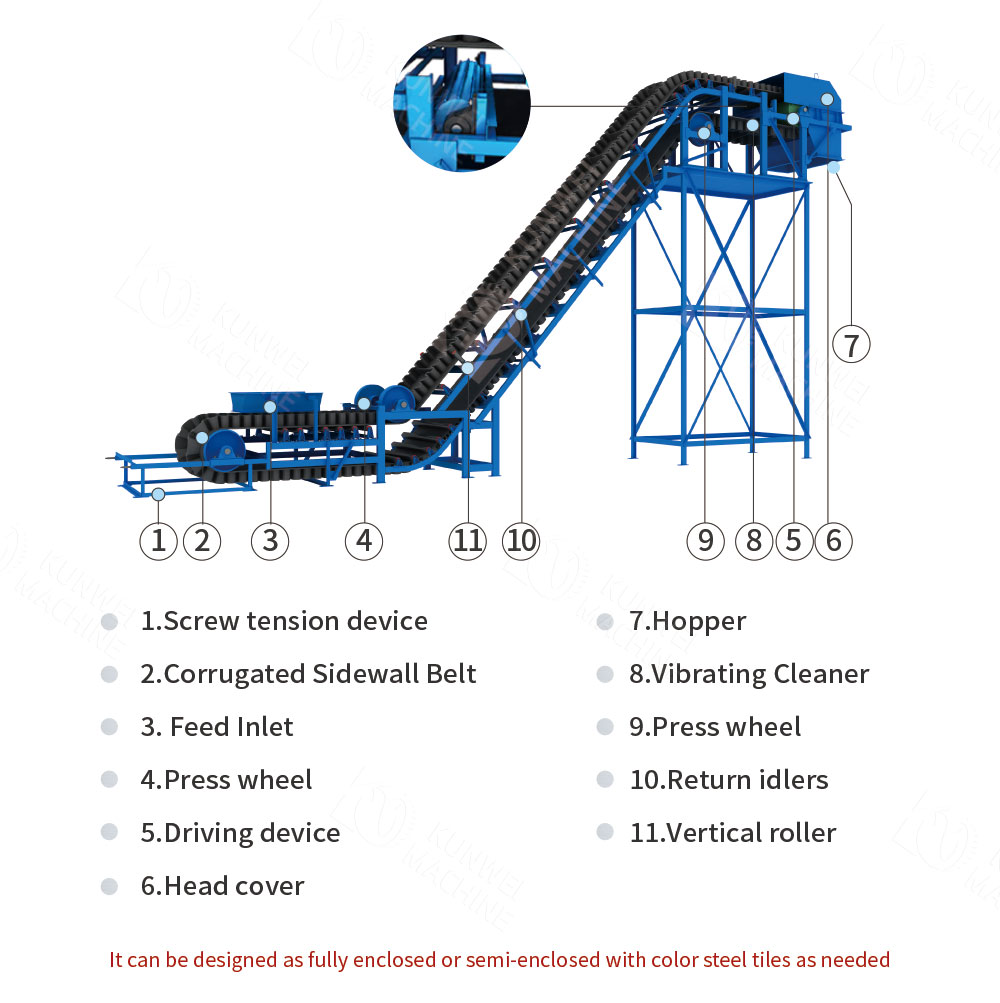

Large inclination conveying relies on the coordinated function of three critical components:

– Base Belt (High Cross-Rigidity)

The base belt provides structural stiffness across the width. High cross-rigidity prevents belt sagging and maintains sidewall geometry, especially on the return side.

– Corrugated Sidewalls

Flexible, heat-vulcanized sidewalls contain the material and prevent rollback at steep angles. Their corrugated shape allows repeated flexing without cracking.

– Transverse Cleats

Cleats generate the lifting force. They divide the belt into pockets and actively carry the load upward, even at near-vertical inclinations.

A standard flat or chevron belt fails at steep angles because gravity overcomes friction, causing material rollback. In contrast, the cleats physically support the load, while the sidewalls eliminate lateral spillage.

Solving the Space Constraint Problem (Scenario Analysis)

Sidewall belt conveyors are specifically engineered for limited-footprint environments:

Best-fit scenarios

– Existing plant expansions with no room for long conveyors

– Underground tunnels or shaft feeding systems

– Port terminals with fixed infrastructure

– Cement plants retrofitting preheater or silo feeding lines

Layout flexibility

– Configurable in **L-shape, S-shape, or C-shape**

– Easily routed around columns, buildings, or equipment

– Eliminates multiple transfer points, reducing spillage and degradation

Typical conveyed materials

– Coal and coke

– Crushed ore and aggregates

– Sand and fertilizer

– Grain and other free-flowing bulk solids

By elevating material at steep angles, this system can reduce the required footprint by up to 70% compared to conventional inclined belt layouts.

Sidewall Conveyor vs. Bucket Elevator (Trade-offs)

When vertical lifting is required, bucket elevators are often considered—but they introduce trade-offs.

Bucket Elevator

– Efficient for pure vertical transport

– Typically noisier

– Generates more dust at loading and discharge

– Can damage fragile or abrasive materials

– Maintenance often requires full shutdown

Sidewall Belt Conveyor

– Smooth, continuous conveying path

– Lower material breakage

– Quieter operation

– Open structure simplifies inspection and repair

– Handles combined horizontal and vertical transport in one system

While sidewall conveyors generally have higher belt maintenance costs than flat belts due to sidewall and cleat wear, they often outperform bucket elevators in flexibility, noise control, and overall layout efficiency.

Critical Specification Checks (Verifiable Proof)

Before selecting a large inclination sidewall conveyor, verify the following:

– Base belt cross-rigidity

A belt with insufficient stiffness will collapse on the return run, leading to premature sidewall fatigue.

– Sidewall and cleat bonding method

Integral hot vulcanization provides longer service life than cold bonding or mechanical fastening.

– Cleat height and spacing

Must match material flow characteristics and required lifting angle.

– Pulley diameter and tracking system

Improper pulley sizing accelerates belt fatigue at high angles.

These checks can be validated through belt datasheets, sample inspections, and layout drawings—no assumptions required.

Safety, Standards, and Operational Considerations

Large inclination sidewall belt conveyors are typically designed in compliance with **ISO standards** for belt conveyors.

For outdoor installations, even with an open type design, **rain covers are strongly recommended**. Water accumulation inside cleat pockets increases belt load and can negatively affect drive power and belt life.

For sticky or moist materials, cleaning devices or beaters should be considered. Highly sticky sludge may clog the pockets between cleats and requires special handling solutions.

Conclusion: A Smart Investment for Space-Limited Plants

An open type large inclination sidewall belt conveyor is one of the most effective investments for achieving high-capacity bulk transport in limited space. While maintenance costs are slightly higher than standard flat belts, the ability to lift material at steep angles—up to vertical—often makes it the only viable solution.

For plants constrained by layout, elevation, or retrofit limitations, this system delivers compactness, continuity, and operational efficiency that conventional conveyors cannot match.

Optimize Your Layout

– Get a custom layout drawing

– Consult us for sidewall height and cleat selection

– Evaluate space savings before committing to civil work

A properly engineered sidewall conveyor turns vertical challenges into usable capacity.