Material Specifications for the Frame of Belt Conveyors

News 2025-11-13

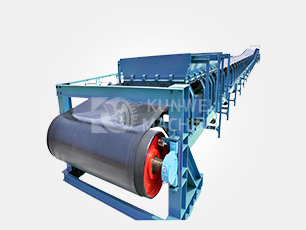

The frame of a belt conveyor serves as its skeletal structure, bearing the weight of both the conveyor belt and the transported materials. The material quality of the frame directly impacts the conveyor’s service life and operational stability.

Currently, belt conveyors used in heavy industries such as coal mining or steel production employ high-quality carbon steel for their entire frame structure, typically with a thickness of approximately 8-10mm. This material offers excellent mechanical properties and weldability, enabling it to withstand heavy loads and impact stresses. It also possesses high corrosion resistance and wear resistance, making it suitable for diverse heavy industrial applications.

Furthermore, to enhance frame quality and longevity, some manufacturers employ corrosion-resistant treatments like surface spraying and galvanization. These processes effectively extend the frame’s lifespan while reducing maintenance and operational costs to a certain extent.

Some may ask: Why not use stainless steel? Because that material is typically reserved for lightweight equipment, such as conveyors handling grain or food products. It is unsuitable for heavy industry.

In summary, for heavy-duty belt conveyors, selecting the appropriate frame material is crucial for stability and longevity. The current use of high-quality carbon steel combined with surface treatment technologies already meets the demands of most transportation scenarios. For additional equipment requirements, inquiries can be directed to the manufacturer, as belt conveyors are typically available for customization. Feel free to leave comments and discuss any questions!