Sidewall Conveyor Belt Manufacturer | 90° Vertical Lift Custom Systems

Solving Bulk Material Transport at 90° Vertical Angles

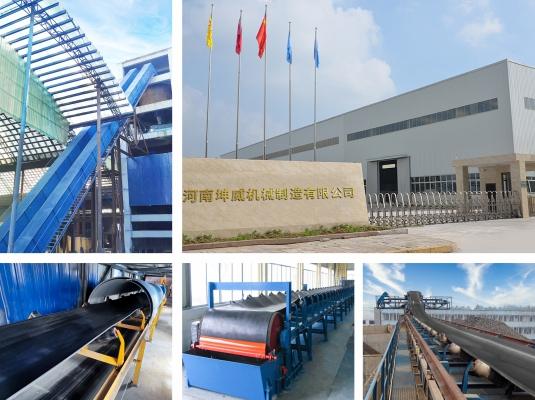

Are you struggling with limited plant space or material rollback on standard conveyors? As a specialized Sidewall Conveyor Belt Manufacturer, we engineer systems that defy gravity. Unlike trading companies that offer “off-the-shelf” belts, we custom mold and vulcanize every cleat and sidewall to ensure zero delamination under high-stress vertical lifting.

Why Procurement Managers Switch to Us:

-

Maximum Angle: Convey up to 90° vertically with zero spillage.

-

Sidewall Height: Custom range from 40mm to 400mm (S-type/W-type).

-

Temperature Range: Proven performance from -30°C to +200°C.

-

Factory Direct: Save 30%+ on costs by skipping the middleman.

What Is a Vertical Conveyor Belt System?

A vertical conveyor belt system utilizes a cross-rigid base belt equipped with corrugated sidewalls and transverse cleats. This unique design creates “pockets” that hold bulk materials securely, allowing them to be transported at steep inclines (greater than 30°) or completely vertically.

Unlike bucket elevators, our sidewall belts offer continuous conveying with lower maintenance costs and less material degradation.

Ideal For:

-

Mining: Coal, copper ore, sand, and gravel.

-

Energy: Biomass, wood chips, and waste-to-energy fuels.

-

Construction: Cement clinker and gypsum.

-

Agriculture: Grains, fertilizers, and powders.

Technical Specifications Comparison (Spec Table)

Don’t settle for vague descriptions. Compare our engineering standards directly against general market options.

| Specification | Our Standard Options | Custom Engineering Capability |

| Cleat Types | T-Type / C-Type / TC-Type | Reinforced bases for heavy ores |

| Cleat Height | 35mm – 360mm | Up to 500mm for high-volume capacity |

| Base Belt Strength | EP 200 – EP 630 | Up to ST 2000 (Steel Cord) for high lifts |

| Sidewall Material | High-abrasion Rubber | Oil-Resistant / Heat-Resistant (HR 200°C) |

| Adhesion Strength | > 12 N/mm (High Bond) | > 15 N/mm (Extreme Duty) |

| Operating Angle | 0° to 90° | Fully vertical twisting paths available |

Engineer’s Note: For vertical lifts exceeding 20 meters, we strictly recommend using TC-Type cleats with metal reinforcement to prevent back-flexing under load.

Factory Direct Quality Control: How We Ensure Zero Delamination

The #1 failure mode of cheap sidewall belts is the sidewall peeling off the base belt. At [BeltConveyorMachine.com], we treat adhesion as the most critical quality metric.

Our 4-Step Adhesion Assurance Process:

-

Base Preparation: We use mechanical grinding (buffing) on the base belt surface to increase bonding surface area by 40%.

-

Hot Vulcanization: Unlike cold bonding used by small workshops, we use hot vulcanization for all sidewalls and cleats. This fuses the rubber chemically, not just physically.

-

Destructive Testing: For every batch of 500m, we perform a random peel test. If adhesion is below 10 N/mm, the entire batch is rejected.

-

Cleat Inspection: Every cleat undergoes a “Hammer Test” and visual inspection for air pockets before packing.

Pricing Factors: What Determines Corrugated Sidewall Belt Price?

We believe in transparent engineering. Your corrugated sidewall belt price is calculated based on specific load requirements, not arbitrary markups.

-

Belt Width & Length: The primary cost driver.

-

Cleat Density: Closer cleat spacing (pitch) increases capacity but adds material cost.

-

Rubber Grade: Heat-resistant (HR) and Oil-resistant (OR) compounds cost 15-25% more than standard abrasion-resistant grades.

-

Fabric Layers: Increasing from EP200 (2-ply) to EP400 (4-ply) adds strength for taller lifts.

Cost Saving Tip: Over-specifying your belt wastes money. Contact our engineers to calculate the exact required belt strength for your TPH (Tons Per Hour).

Why Choose Us as Your Sidewall Conveyor Belt Manufacturer?

-

Speed: We stock standard base belts. Custom orders ship in 15-20 days, compared to 45+ days from major brands.

-

Experience: We have successfully supplied vertical systems for Holcim (Cement) and BHP (Mining) projects.

-

Support: We don’t just sell belts; we provide installation guides and splicing diagrams to ensure your maintenance team gets it right.

Sidewall Conveyor Belt Manufacturer

🚀 Get a Quick Quote for Your Sidewall Conveyor Belt

Stop guessing your specs. Let our engineers verify your design.

Please provide the following for an accurate quote:

-

Material Conveyed: (e.g., Coal, Sand, Grain)

-

Lift Height (m):

-

Desired Capacity (t/h):

Request Custom Quote & Drawing

Want to know more about technical selection? Check our Sidewall Belt Manufacturer Guide.