What parameters are needed to purchase a belt conveyor?

News 2025-05-07

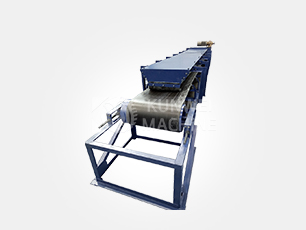

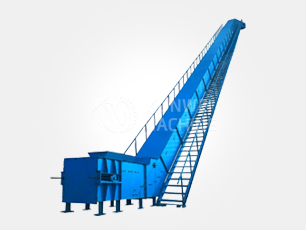

The first thing many people want to know when purchasing a belt conveyor is its price. But the belt conveyor itself belongs to the type of customized equipment, after all, each site situation varies greatly, so we need to provide some parameters or want to achieve the purpose of the site conveyor to meet the basic requirements of the quote! In addition to the basic conveying length, width, and conveying speed of these intuitive size and efficiency indicators, we also need to consider several key elements to ensure that the equipment can meet specific production requirements.

First, the characteristics of the material should not be ignored. Material density, particle size, humidity and abrasiveness will directly affect the choice of belt material and conveyor design structure. For example, for easy to wear or corrosive materials, should use wear-resistant, corrosion-resistant special material belt.

Second, the inclination angle is also an important consideration. Different inclination angles have a significant impact on the power requirements of the conveyor, drive mode and even the overall structure. Large angle conveying often requires stronger power support and special anti-skid design.

Third, the working environment conditions are equally critical. For example, whether it needs to be used outdoors, whether there are explosion-proof, dust-proof, waterproof and other special requirements, which are directly related to the shell material, sealing performance and electrical configuration of the conveyor.

In addition, ease of maintenance and operation is a point of increasing importance in modern industrial procurement. This includes whether it is easy to carry out belt replacement, adjustment and troubleshooting, as well as whether it is equipped with intelligent monitoring and alarm systems in order to detect and deal with potential problems in a timely manner. Therefore, when purchasing belt conveyors, material characteristics, inclination angle, working environment and ease of maintenance and other dimensions should be taken into account to ensure that the selected equipment is not only energy-efficient operation, but also adapt to the complexity of the changing industrial application scenarios.